Cooling method for stainless steel damping plate

A cooling method and vibration damping plate technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as C-bending, and achieve the effect of uniform edge peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and implementation methods.

[0020] A method for cooling a stainless steel damping plate, comprising the steps of:

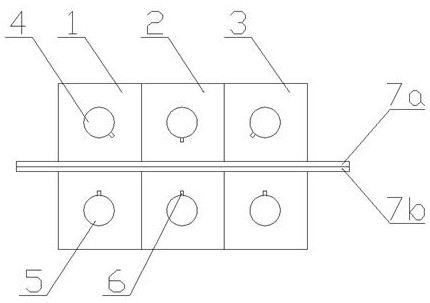

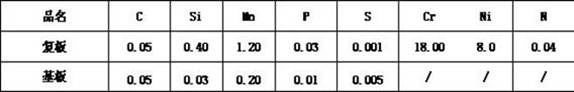

[0021] a. If figure 1 As shown, water-cooling zone 1, water-cooling zone 2 and water-cooling zone 3 are arranged in sequence from left to right. Water-cooling zone 1 includes symmetrically arranged upper cooling water pipes 4 and lower cooling water pipes 5, and the upper cooling water pipes 4 and the lower cooling water pipes The water pipes 5 are equipped with a number of cooling nozzles 6, and the structures of the second water-cooling zone 2, the third water-cooling zone 3 and the first water-cooling zone 1 are the same, specifically, the cooling nozzles 6 are rotatable nozzles;

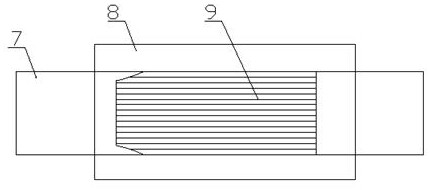

[0022] b. Put the stainless steel damping plate 7 between the upper cooling water pipe 4 and the lower cooling water pipe 5 and drive it, passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com