A method for nano-injection molding of high-binding force aluminum or aluminum alloy surface

A nano-injection molding, aluminum alloy surface technology, applied in the direction of coating, can solve the problems of good adhesiveness, uneven resin, instability, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for nano-injection molding on the surface of a high-bonding aluminum alloy, comprising the following steps in sequence:

[0029] (1) Pretreatment: Pretreatment is to remove the nano-scale natural oxide layer on the surface of aluminum or aluminum alloy by one of the treatment methods of polishing, polishing, tumbling, sandblasting or shot blasting. Here, the polishing process is selected;

[0030] (2) Pre-corrosion: soak the treated metal in 5wt.%H 2 SO 4 and 1wt%H 3 PO 4 Composition of mixed acid, soaking temperature 30 o C, for 5 minutes, chemically etched corrosion holes, then washed with pure water, and dried with cold air;

[0031] (3) DC galvanic corrosion: The pre-corroded metal is used as the anode, and the graphite is used as the cathode. At the same time, it is immersed in a mixed corrosion solution and connected to a DC power supply. The mixed corrosion solution includes 1wt.% hydrochloric acid, 0.5wt.% sulfuric acid, 0.2 wt.% .% oxalic acid and...

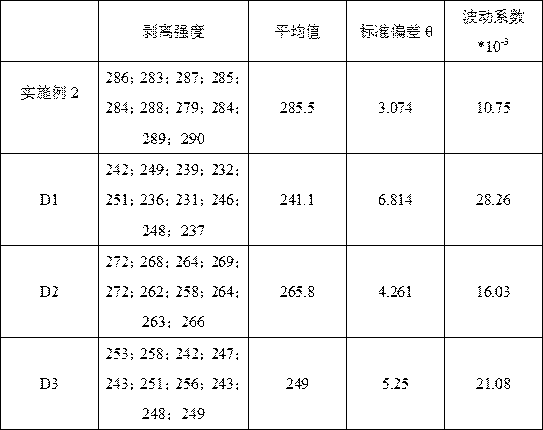

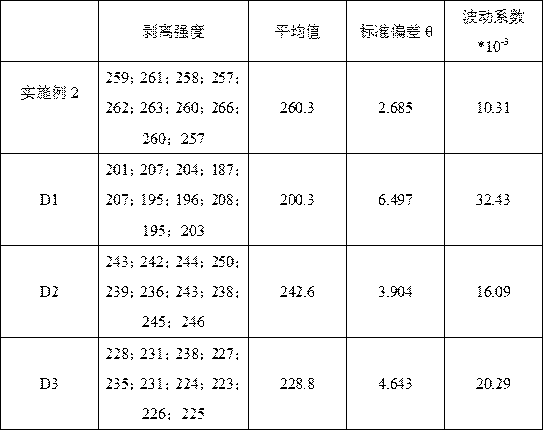

Embodiment 2

[0036] A method for nano-injection molding on the surface of a high-bonding aluminum alloy, comprising the following steps in sequence:

[0037] (1) Pretreatment: Pretreatment is to remove the nanoscale natural oxide layer on the surface of aluminum or aluminum alloy by one of polishing, polishing, tumbling, sandblasting or shot blasting. Here, the polishing process is selected;

[0038] (2) Pre-corrosion: soak the treated metal in 7wt.%H 2 SO 4 and 5wt%H 3 PO 4 Composition of mixed acid solution, soaking temperature 40 o C, for 7 minutes, chemically etched out corrosion holes, then washed with pure water, and dried with cold air;

[0039] (3) DC galvanic corrosion: The pre-corroded metal is used as the anode, and the graphite is used as the cathode. At the same time, it is immersed in a mixed corrosion solution and connected to a DC power supply. The mixed corrosion solution includes 2wt.% hydrochloric acid, 0.75wt.% sulfuric acid, 0.5wt% .% oxalic acid and 0.12wt.% AlCl...

Embodiment 3

[0044] A method for nano-injection molding on the surface of a high-bonding aluminum alloy, comprising the following steps in sequence:

[0045] (1) Pretreatment: Pretreatment is to remove the nano-scale natural oxide layer on the surface of aluminum or aluminum alloy by one of the treatment methods of polishing, polishing, tumbling, sandblasting or shot blasting. Here, the polishing process is selected;

[0046] (2) Pre-corrosion: soak the pretreated metal in 10wt.%H 2 SO 4 and 5wt%H 3 PO 4 Composition of mixed acid solution, soaking temperature 40 o C, for 10 minutes, chemically etched corrosion holes, then washed with pure water, and dried with cold air;

[0047] (3) DC galvanic corrosion: The pre-corroded metal is used as the anode, and the graphite is used as the cathode. At the same time, it is immersed in a mixed corrosion solution and connected to a DC power supply. The mixed corrosion solution includes 3wt.% hydrochloric acid, 1wt.% sulfuric acid, 1wt.% Oxalic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com