Preparation method of aluminum or aluminum alloy material with high pore density

An aluminum alloy material, aluminum alloy technology, applied to aluminum and aluminum alloy surface treatment, in the field of metal surface nano-injection, it can solve the problem of limiting operation, affecting bonding force and later stability, corrosion-resistant sputtering metal can not be effectively removed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The processing method about aluminum or aluminum alloy metal substrate mainly includes the following steps (as attached Figure 4-5 shown):

[0078](1) Pretreatment: Mechanically treat the surface of aluminum or aluminum alloy metal to remove the nano-scale natural oxide layer on the surface of aluminum or aluminum alloy. The oxide layer has low bonding force with the substrate and poor physical and chemical properties. Therefore, The process of mechanical pretreatment is indispensable. The mechanical treatment includes one of grinding, polishing, tumbling, sandblasting or shot blasting; followed by alkaline or acidic degreasing agent to chemically remove the grease on the metal surface, Since a layer of oil will inevitably adhere to the metal surface when mechanically treating the metal substrate, in order to ensure the firm combination of the substrate and the oxide film or nano-injection material, the oil on the metal surface must be removed.

[0079] Its chemical d...

Embodiment 2

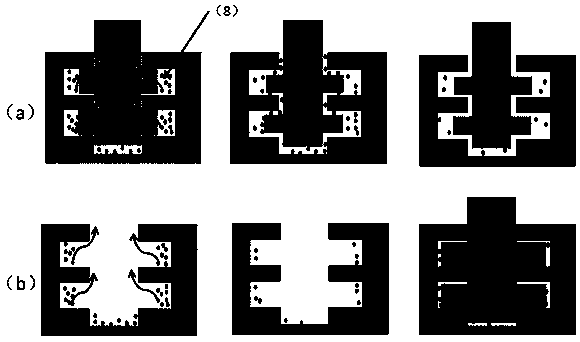

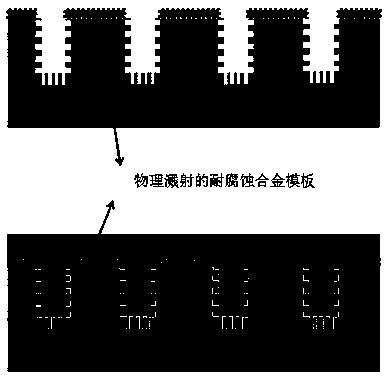

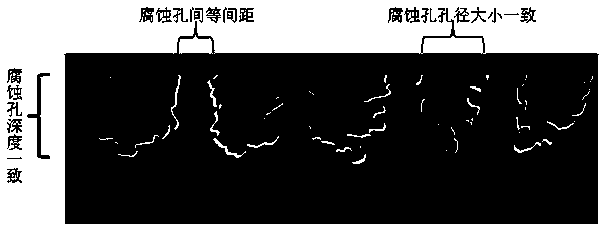

[0091] As mentioned above, the inventor CN201711256603A patent prepares ordered micron-scale pores by preparing templates: specific steps (1) Use one of the treatment methods of polishing, polishing, rolling, sandblasting or shot blasting to remove the nanoscale holes on the metal surface. (2) soak the treated metal in an alkali metal cleaning solution; (3) wash with pure water and dry; (4) cover metal Ni, Cr, Cu or their alloys on the surface of the metal substrate A corrosion-resistant metal template, the metal template is divided into a blank area and a metal area; (5) physically sputtering a corrosion-resistant metal on the substrate surface of the metal template in step (4); (6) removing the corrosion-resistant metal template, the The metal substrate after physical sputtering treatment is immersed in acid corrosion solution, and the substrate is corroded multiple times to corrode uniformly distributed micron-scale corrosion holes, which are washed with pure water, and the ...

Embodiment 3

[0113] The metal substrate obtained in Example 1 was subjected to PPS nano-injection molding.

[0114] Specific steps are as follows:

[0115] (1) Mechanical polishing; (2) Chemical degreasing; (3) Surface coating with corrosion-resistant coating; (4) Laser engraving grooves to expose aluminum or aluminum alloy metal; (5) Exposed aluminum or aluminum alloy metal (6) freeze-drying; (7) chemical corrosion to obtain mesopores; (8) heat treatment to remove moisture and coating in the metal substrate; (9) nano-injection molding, where the The resin melting temperature of the nano-injection molding is 200-300°C, the temperature of the nano-injection molding is 70-90°C, the pressure of the injection molding is 70-130Mpa, and the speed of the nano-injection molding is 400-900mm / s.

[0116] Among them, mechanical polishing is selected from polishing to remove the nano-scale natural oxide layer on the surface of aluminum or aluminum alloy.

[0117] Wherein use alkaline degreaser degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com