A binder component for high-strength metal injection molding and its preparation method

An injection molding, high-strength technology, used in adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

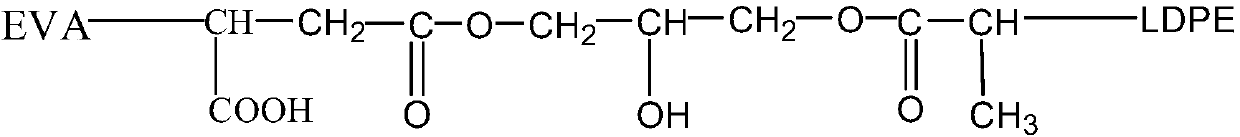

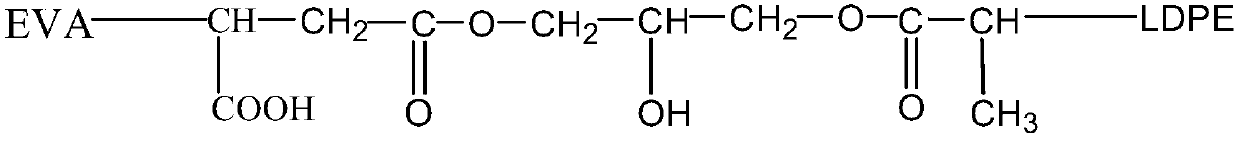

Method used

Image

Examples

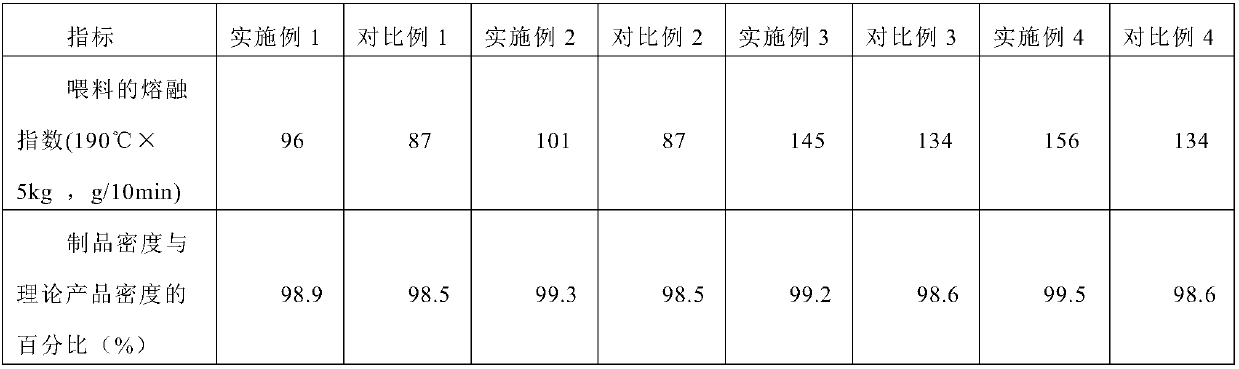

Embodiment 1

[0024] Reaction raw materials and mass percent are respectively: LDPE-g-GMA 50% (grafting rate 1.5%), EVA-g-MAH50% (grafting rate 1.5%) and aluminum acetylacetonate (1% of the total mass of reaction raw materials ). The raw materials are put into a high-speed mixer, mixed evenly, and then melted and extruded through an extruder, the extrusion temperature is 220°C, and the main screw speed is 200r / min. The components and mass percentage of the binder are: 8% reactant of LDPE-g-GMA and EVA-g-MAH, 5% low-density polyethylene LDPE, 4% ethylene acetate EVA, 48% paraffin, 5% stearic acid , POM 30%. Add each component into a high-speed mixer, mix evenly, and then melt and extrude through an extruder (the extrusion temperature is 180°C, the main screw speed is 180r / min) and make it into pellets. The obtained granules are binders, which are uniformly mixed with metal powders in an internal mixer (the mass percentages of binders and metal powders are 7% and 93% respectively) to obtain...

Embodiment 2

[0027] The reaction raw materials and mass percentages are respectively: LDPE-g-GMA60% (grafting ratio 2%), EVA-g-MAH 40% (grafting ratio 2%) and 1,2-dimethylimidazole (reaction raw material 1% of the total mass). The raw materials are put into a high-speed mixer, mixed evenly, and then melted and extruded through an extruder, the extrusion temperature is 220°C, and the main screw speed is 200r / min. The components and mass percentage of the binder are: 8% reactant of LDPE-g-GMA and EVA-g-MAH, 5% LDPE, 4% EVA, 48% paraffin, 5% stearic acid, 30% polyoxymethylene . Add each component into a high-speed mixer, mix evenly, and then melt and extrude through an extruder (the extrusion temperature is 180°C, the main screw speed is 180r / min) and make it into pellets. The obtained granules are binders, which are uniformly mixed with metal powders in an internal mixer (the mass percentages of binders and metal powders are 7% and 93% respectively) to obtain feed materials, which are then...

Embodiment 3

[0030] The mass percentages of the raw materials are: LDPE-g-GMA 50% (grafting rate 2%), EVA-g-MAH 50% (grafting rate 2%) and aluminum acetylacetonate (1.5% of the total mass of the reaction raw materials). The raw materials are put into a high-speed mixer, mixed evenly, and then melted and extruded through an extruder, the extrusion temperature is 220°C, and the main screw speed is 200r / min. The components and mass percentages of the binder are: 10% of the reactant of LDPE-g-GMA and EVA-g-MAH, 4% of LDPE, 3% of EVA, 48% of paraffin, 10% of stearic acid, 25% of polyoxymethylene %. Add each component into a high-speed mixer, mix evenly, and then melt and extrude through an extruder (the extrusion temperature is 180°C, the main screw speed is 180r / min) and make it into pellets. The obtained granules are binders, which are uniformly mixed with metal powders in an internal mixer (the mass percentages of binders and metal powders are 7% and 93% respectively) to obtain feed materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com