Winding, bundling and positioning structure based on automobile wire harness

A technology of automobile wiring harness and positioning structure, which is applied to the parts and packaging of bundling machinery, can solve the problems of harming the body of operators, heavy workload of workers, low efficiency, etc., so as to reduce labor costs, workload, and labor. The effect of time of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

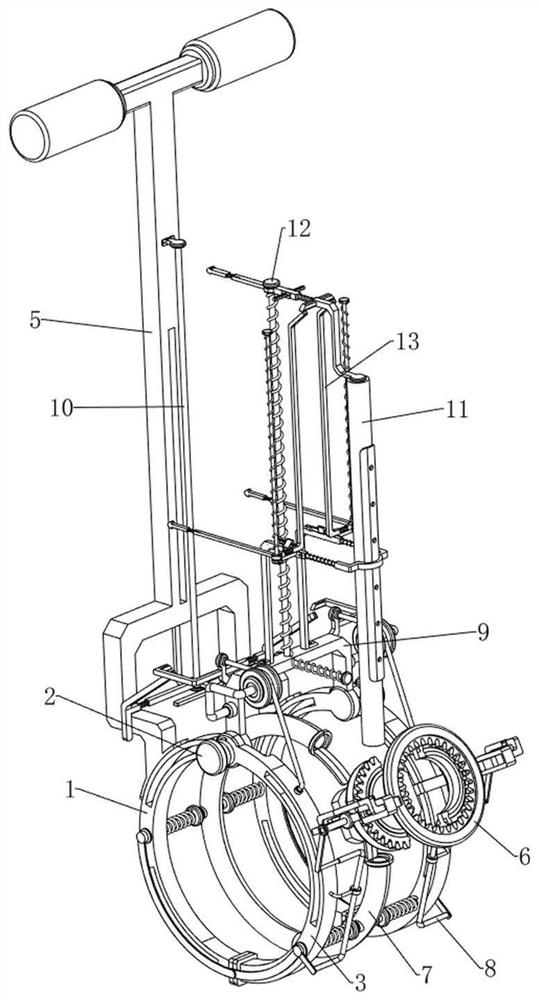

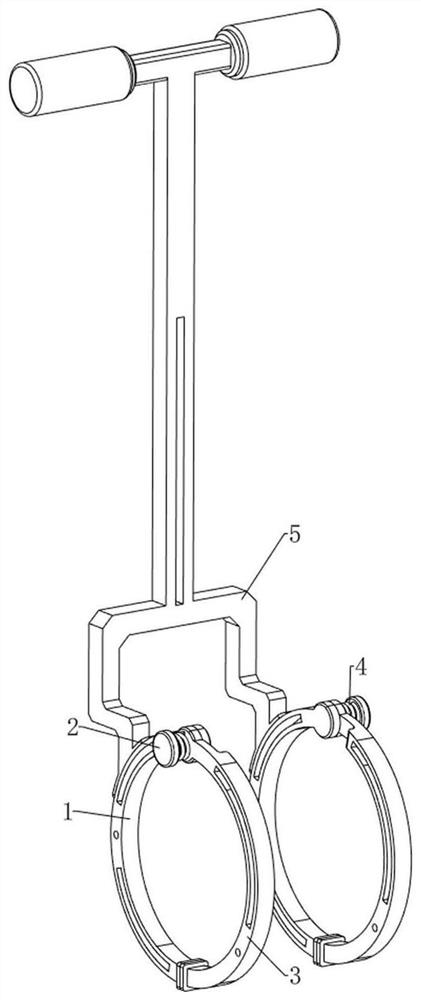

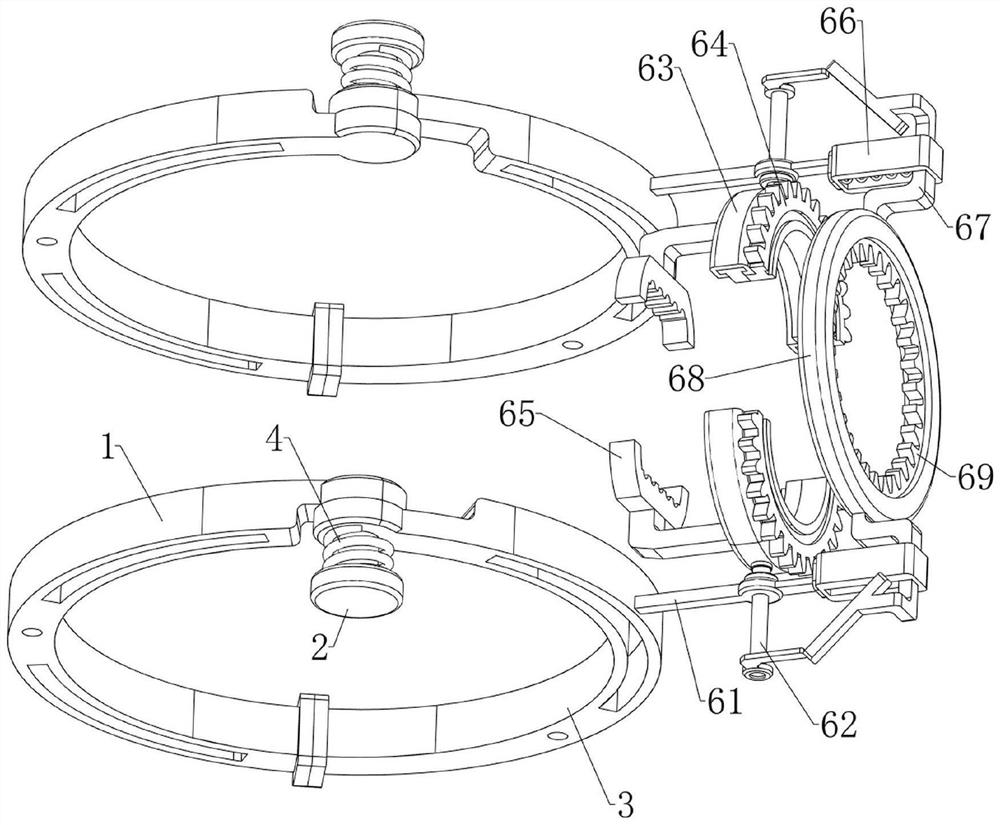

[0042] A structure based on the winding and bundling of automobile wire harnesses and its positioning, such as Figure 1-7 As shown, it includes a first positioning ring 1, a first connecting rod 2, a second positioning ring 3, a torsion spring 4, a connection handle 5, a binding mechanism 6, a guiding mechanism 7 and a pulling mechanism 8. The first positioning ring 1 There are two in total, the two first positioning rings 1 are placed symmetrically front and back, the upper sides of the two first positioning rings 1 are welded with the first connecting rod 2, and the two first connecting rods 2 are provided with the second positioning through the rotating shaft Ring 3, the torsion spring 4 is connected between the two second positioning rings 3 and the first connecting rod 2 on the same side, the two second positioning rings 3 are in contact with the first positioning ring 1 on the same side, the first positioning A connection handle 5 is welded between the upper sides of th...

Embodiment 2

[0048] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, an opening mechanism 9 is also included, and the opening mechanism 9 includes a second connecting block 91, a pulley 92, a second connecting rod 93, a third connecting block 94, a pull cord 95, a fourth return spring 96 and a fourth connecting block 97, a second connecting block 91 is welded between the tops of the two first positioning rings 1, the upper side of the second connecting block 91 is rotatably equipped with pulleys 92 on the front and rear sides, and the sliding type in the middle of the second connecting block 91 is provided with a second Connecting rod 93, the third connecting block 94 is welded on the left side of the second connecting rod 93, the fourth return spring 96 is connected between the second connecting rod 93 and the second connecting block 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com