Automatic flow control method for perfusion suction system

A suction tube and suction device technology, applied in the field of medical devices, can solve the problems of increased surgical complexity, insufficient safety and stability, difficult surgery, etc., so as to reduce the time consumed by manual operations, simplify the complexity of surgery, and speed up the surgical process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following is only exemplary and does not limit the protection scope of the present invention.

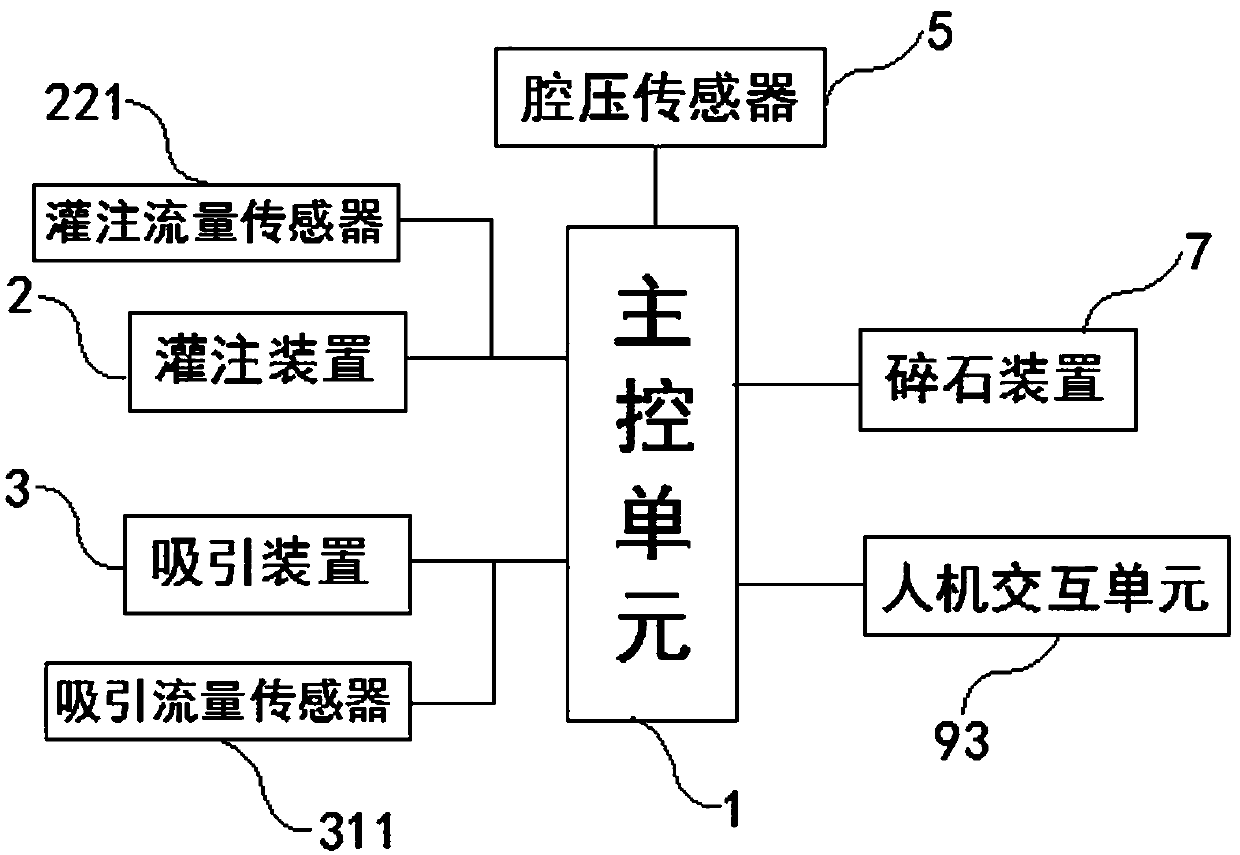

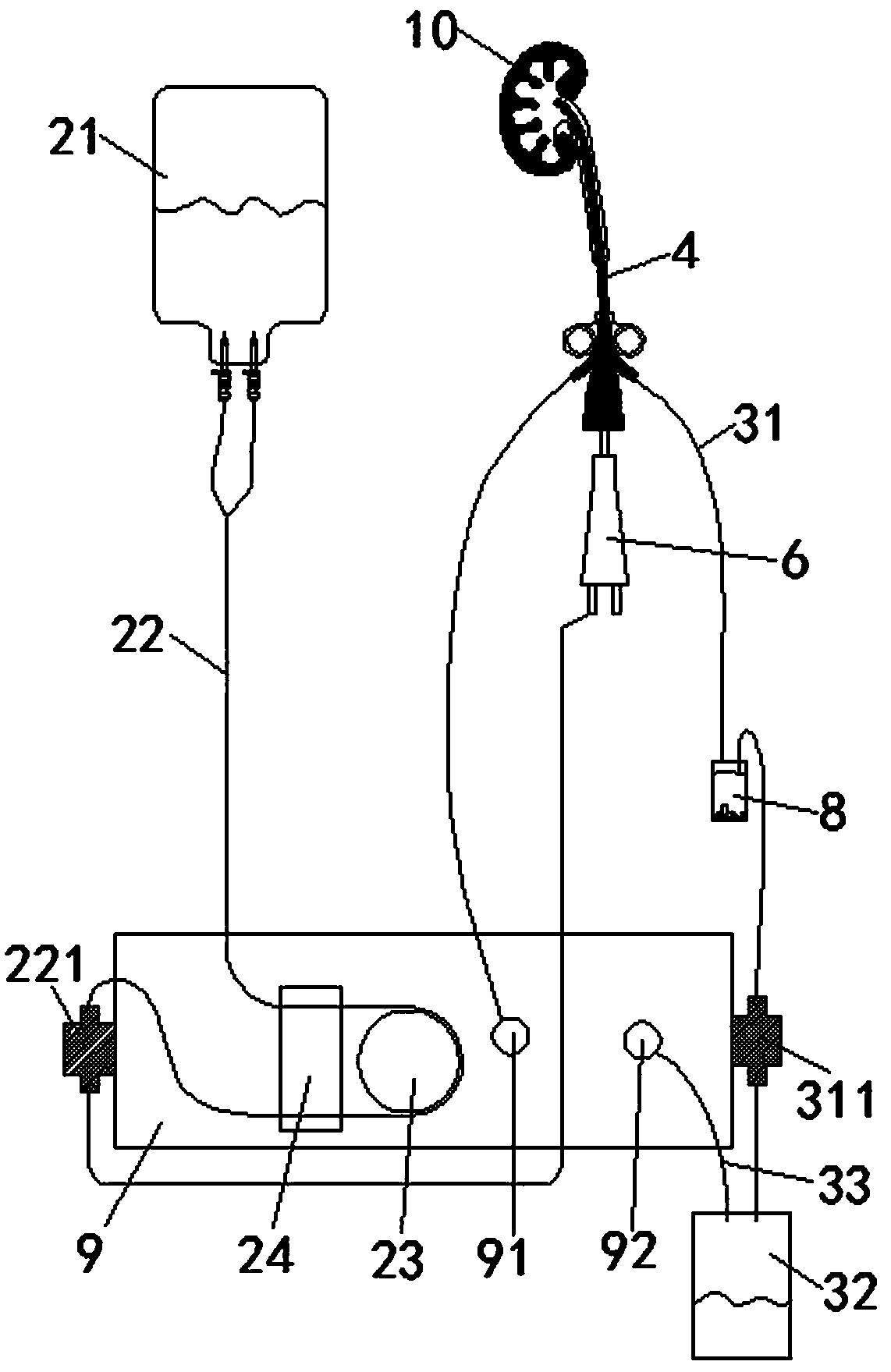

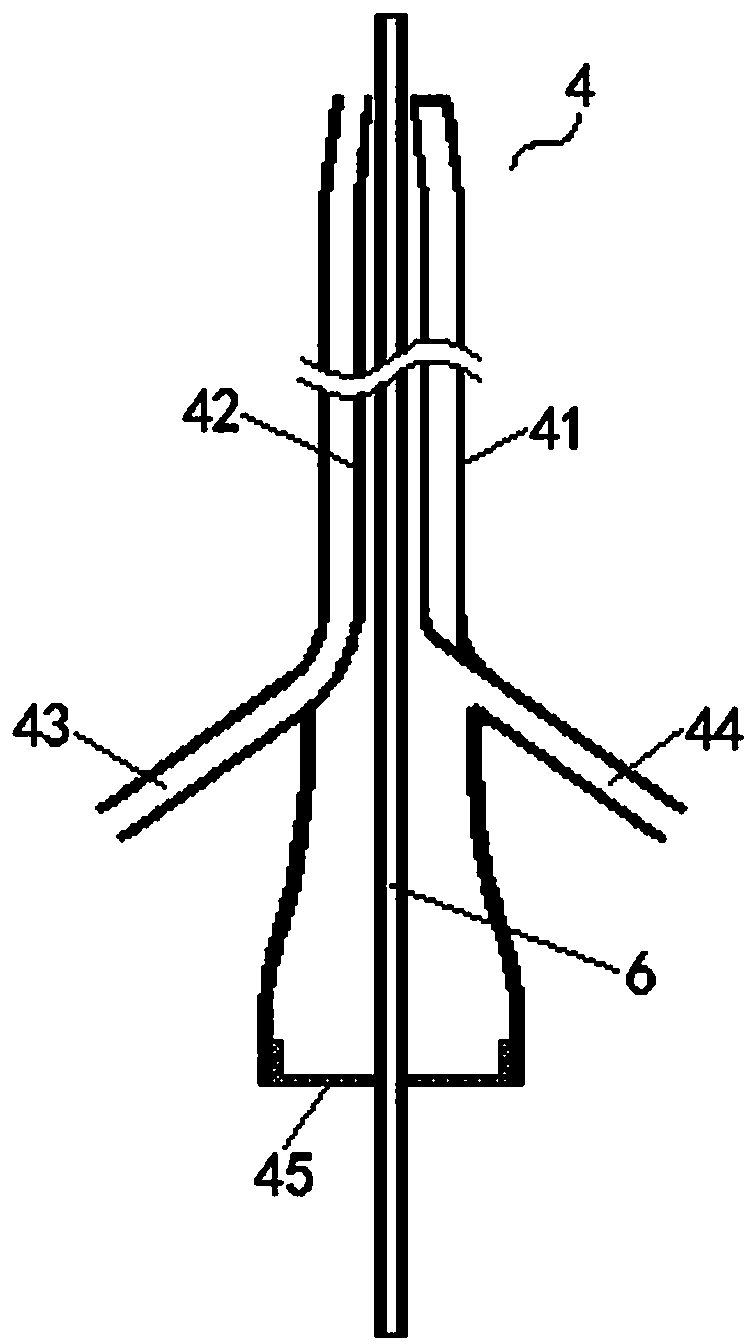

[0033] Such as figure 1 and 2 As shown, an automatic flow control method for a perfusion suction system described in this embodiment, the perfusion suction system includes a main control unit 1, a perfusion device 2, a suction device 3, a mirror sheath 4, and a The chamber pressure sensor 5, the perfusion device 2, the suction device 3 and the chamber pressure sensor 5 are all connected to the main control unit 1.

[0034] In this embodiment, the perfusion device 2 includes a liquid storage device 21, a hose 22 connecting the liquid storage device and the mirror sheath, and a driving device for driving the liquid in the hose. Further, the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com