Preparation method of p-anisidine

A technology for p-aminoanisole and nitrobenzene, which is applied in the preparation of amino hydroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of complex preparation process, secondary pollution, poor quality, etc. The effect of simple process, mild reaction conditions and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

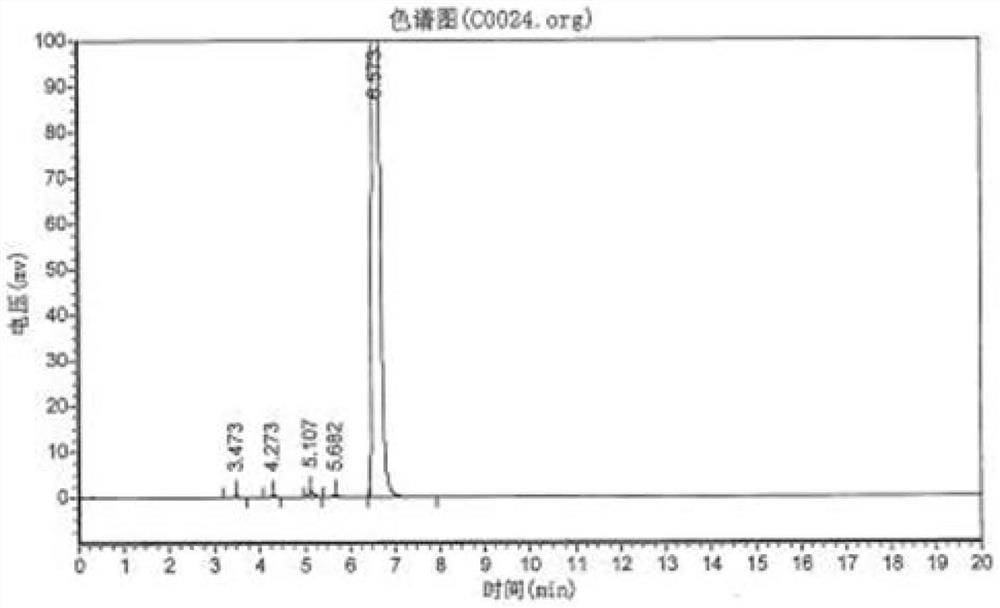

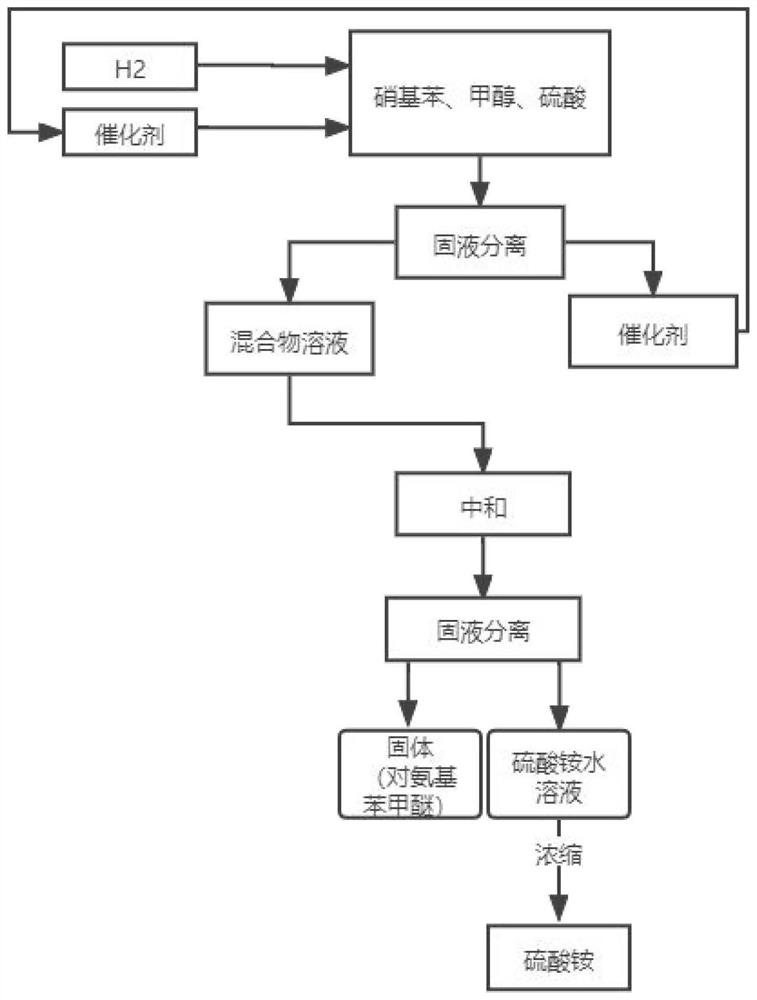

[0019] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0020] One, the preparation of p-aminoanisole:

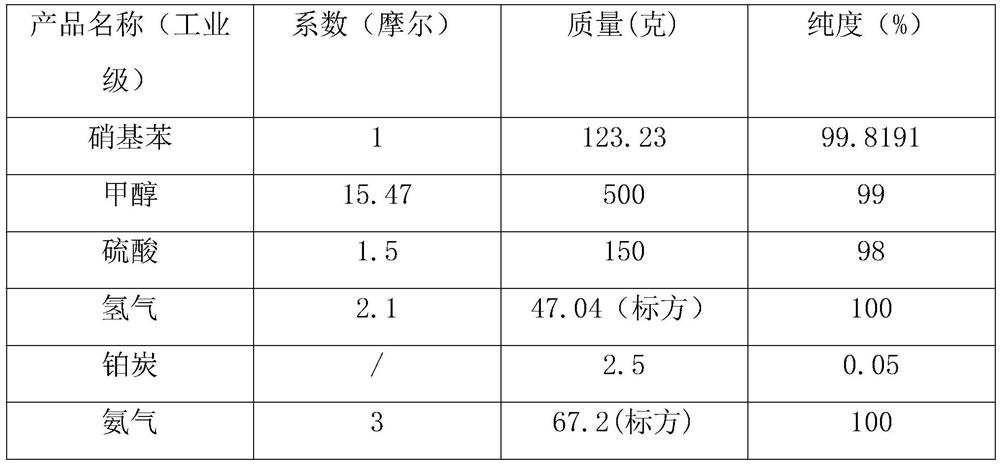

[0021] The raw material sample specifications for preparing p-aminoanisole are shown in the table below:

[0022]

[0023] Prepare as follows:

[0024] S1. Using methanol, nitrobenzene, and sulfuric acid as raw materials, add catalyst Pt-c and feed hydrogen, wherein the operating pressure of hydrogen is 0.3-0.5MPa;

[0025] S2. Separating the solid and liquid in S1, adding the separated Pt-c to S1 to continue the reaction, wherein the equivalent diameter of Pt-c is 0.01mm-10.0mm, and hydrogen is introduced, and the operating pressure of hydrogen is 0.3- 0.5MPa, the liquid obtained after separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com