Aluminum-containing cold forging steel acid-soluble aluminum control method

A control method, the technology of acid-soluble aluminum, applied in the field of steel smelting, can solve the problems of increasing the fixed oxygen cost of the argon blowing station, occupying the time of the argon blowing station for aluminum lines, and the large loss of acid-soluble aluminum, so as to save the cost of oxygen fixing inspection, High production efficiency and the effect of increasing the content of acid-soluble aluminum in molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to deepen the understanding of the present invention, the present invention will be further detailed in connection with the present invention, and the present embodiment is intended to explain the present invention and does not constitute a defined the scope of the invention.

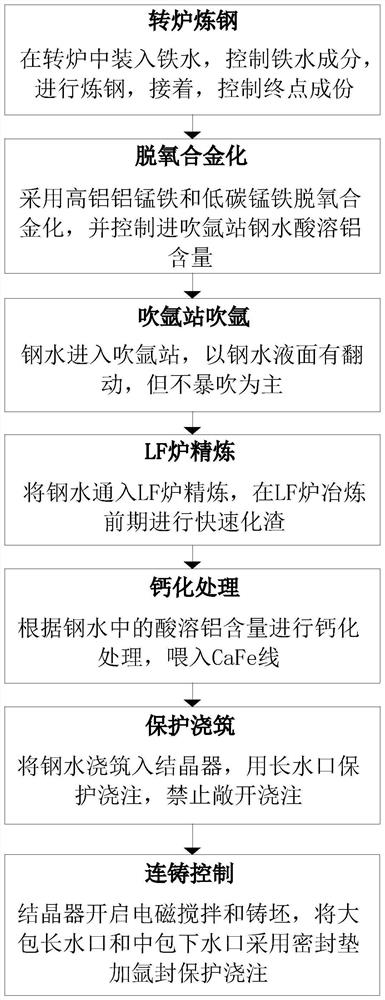

[0041] according to figure 1 As shown, the present embodiment proposes an aluminum-free-aluminum-free aluminum-soluble aluminum control method, including the following steps:

[0042] Step 1: Converter steelmaking

[0043] Iron water is loaded into the converter, the iron water requirements: silicon = 0.30 0.80%, manganese ≤ 0.50%, phosphorus ≤0.15%, sulfur ≤ 0.030%, temperature ≥1250 ° C, steelmaking, converter adopt slag, strict Controlling the groove of the steel is less than 50 ppm, then controls the finite component of the converter: carbon = 0.05-0.09%, phosphorus ≤ 0.012%, sulfur ≤0.020%, the end point of the converter, control oxygen content ≤900 ppm;

[0044] Step 2: Deoxidation

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com