Manufacturing method for overcoming hot-rolled soft and hard edges of ferritic stainless steel

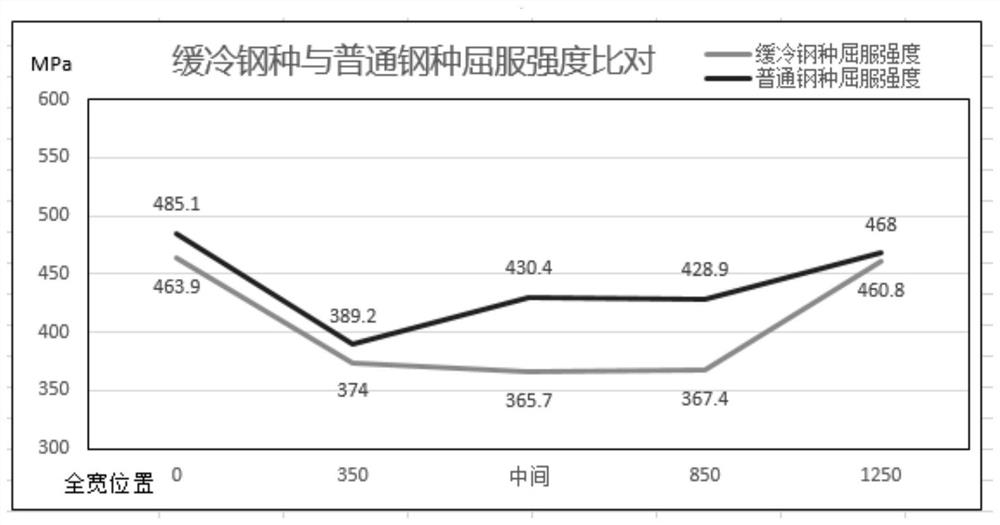

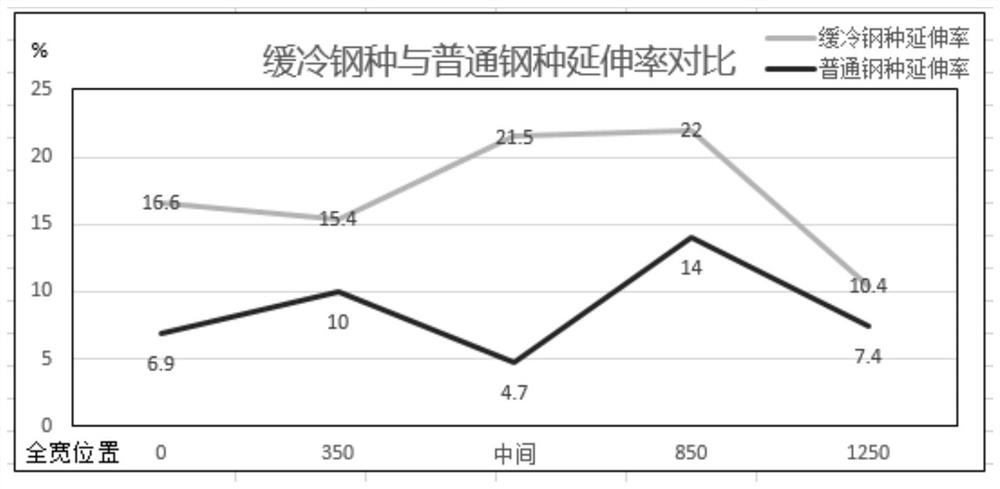

A manufacturing method, stainless steel technology, applied in the field of metallurgical steel rolling, to achieve the effect of solving poor forming performance, increasing elongation, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

[0022] In the embodiment of the present invention, the production of black-skinned steel coils without soft and hard edges and the hot-rolled steel coils of the present invention with soft and hard edges should be scheduled sequentially, and the black-skinned steel coils should be scheduled 3-4 hours in advance.

[0023] See Table 1 for the steel composition of the embodiment; see Table 2 for the hot-rolling process parameters of the embodiment;

[0024] Table 1 embodiment steel composition (wt%)

[0025] C Si mn P S Ni Cr Mo Cu N 0.04 0.35 0.334 0.026 0.003 0.141 16.15 0.008 0.045 0.045

[0026] Table 2 embodiment hot rolling process parameter

[0027]

[0028]

[0029] Table 3 Placement of heat preservation pit

[0030]

[0031] 1) Heating process of the heat preservation pit: According to the production time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com