Foundation pit support structure and construction method thereof

A technology for foundation pit enclosure and enclosure structure, which is applied in foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of reducing the speed of overall civil construction, long construction period, etc., and achieves easy implementation, convenient construction, enhanced holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

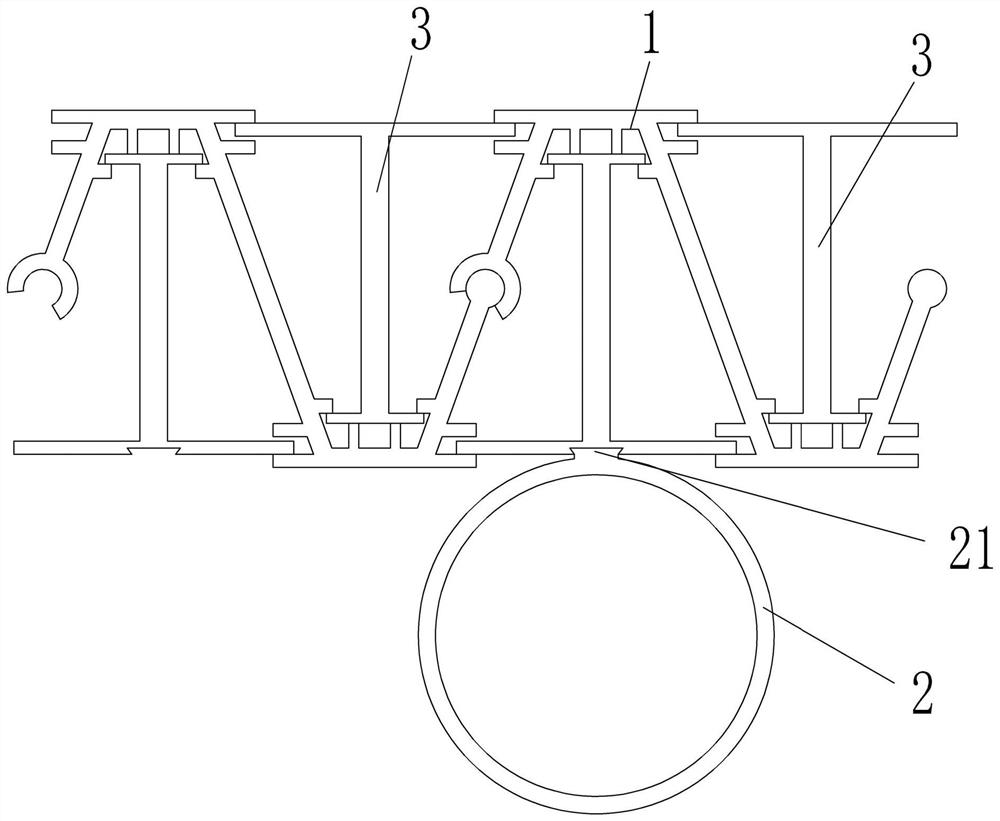

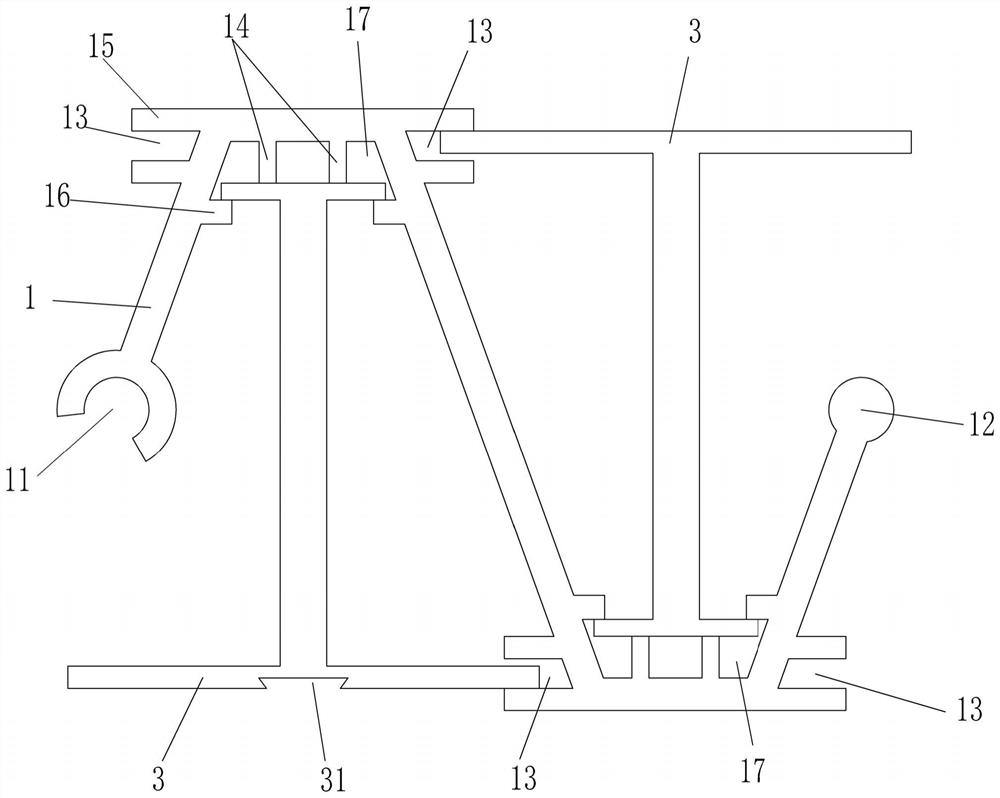

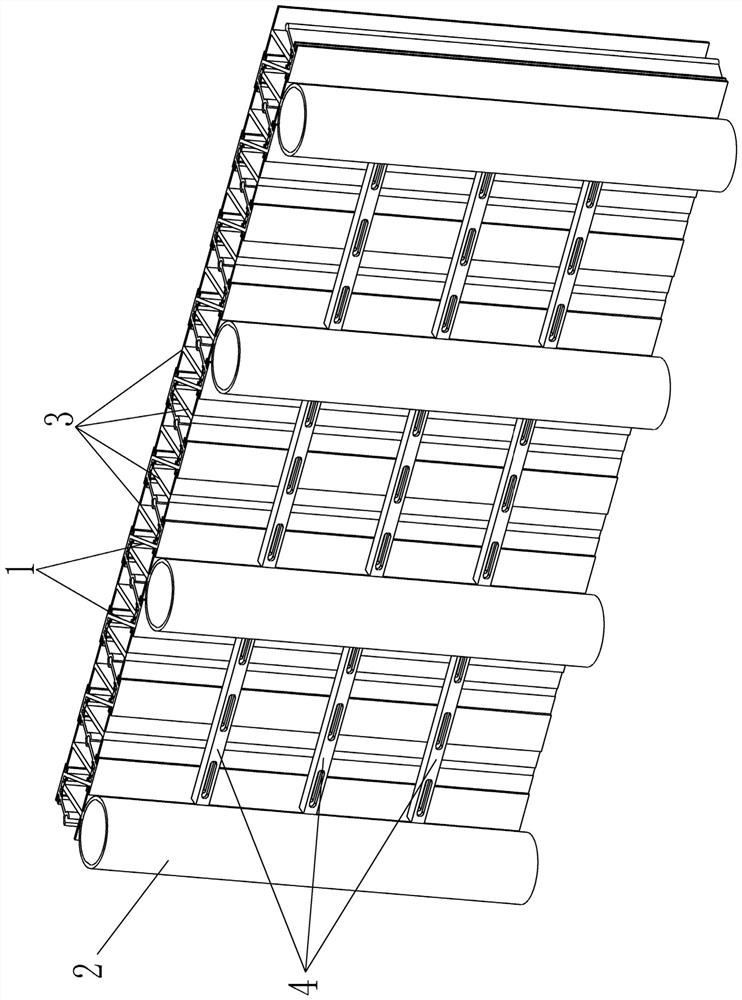

[0051] The two steel sheet piles 1 are occluded and connected to each other through the occlusal structure provided to form a continuous enclosure structure; the I-shaped steel pile 3 is clamped at the corner 17 on both sides of the steel sheet pile 1, and the I-shaped steel pile 3 and A triangular structure is formed between two connected steel sheet piles 1; several steel pipe piles 2 are connected to the non-blocking side of the enclosure structure, and the steel pipe piles 2 are connected to the I-shaped steel piles 3 at intervals; The steel sheet piles 1 between the two steel pipe piles 2 are connected by multiple sets of beams 4 , and the two ends of the beams 4 are respectively welded to the two steel pipe piles 2 .

[0052] Among them, this embodiment one can be applied to the enclosure structure formed by the enclosure in the deeper foundation pit; through the connection of the steel sheet pile 1 and the I-shaped steel pile 3, it forms a stable triangular structure, wh...

Embodiment 2

[0054] The two steel sheet piles 1 are occluded and connected to each other through the occlusal structure provided to form a continuous enclosure structure; the I-shaped steel pile 3 is clamped at the corner 17 on the same side of the steel sheet pile 1, and the I-shaped steel pile 3 and A triangular structure is formed between two connected steel sheet piles 1; wherein, the corner 17 on the other side of the steel sheet pile 1 is not clamped with an I-shaped steel pile 3; block side, and the steel pipe piles 2 are connected to the I-shaped steel piles 3 at intervals; the steel sheet piles 1 between two adjacent steel pipe piles 2 are connected by multiple sets of beams 4, and Welded on two steel pipe piles 2 respectively.

[0055] Among them, this embodiment one can be applied to the enclosure structure formed by the enclosure in the deeper foundation pit; through the connection of the steel sheet pile 1 and the I-shaped steel pile 3, it forms a stable triangular structure, ...

Embodiment 3

[0057] The two steel sheet piles 1 are interlocked and connected to each other through the interlocking structure provided therein, forming a continuous enclosure structure.

[0058] Wherein, the third embodiment can be applied to an enclosure structure formed by enclosure in a relatively shallow foundation pit; the structure is simple, the construction is convenient, easy to implement, and high in safety.

[0059] Additionally, if Figure 1-4 As shown, the present invention provides a kind of construction method of above-mentioned foundation pit enclosure structure, comprises the following steps:

[0060] S1, implanting the steel sheet pile 1; in the soft soil layer, insert the steel sheet pile 1 into the soft soil layer directly along the boundary line of the foundation pit enclosure; the clamping strip 12 provided by the steel sheet pile 1 is inserted into the adjacent steel plate The pile 1 is provided in the first clamping groove 11.

[0061] S2, inserting the I-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com