Fabricated tunnel structure and construction method thereof

A technology of tunnel structure and construction method, which is applied to tunnels, tunnel linings, shaft equipment, etc., and can solve problems such as cumbersome workmanship, voids behind walls, and slow construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

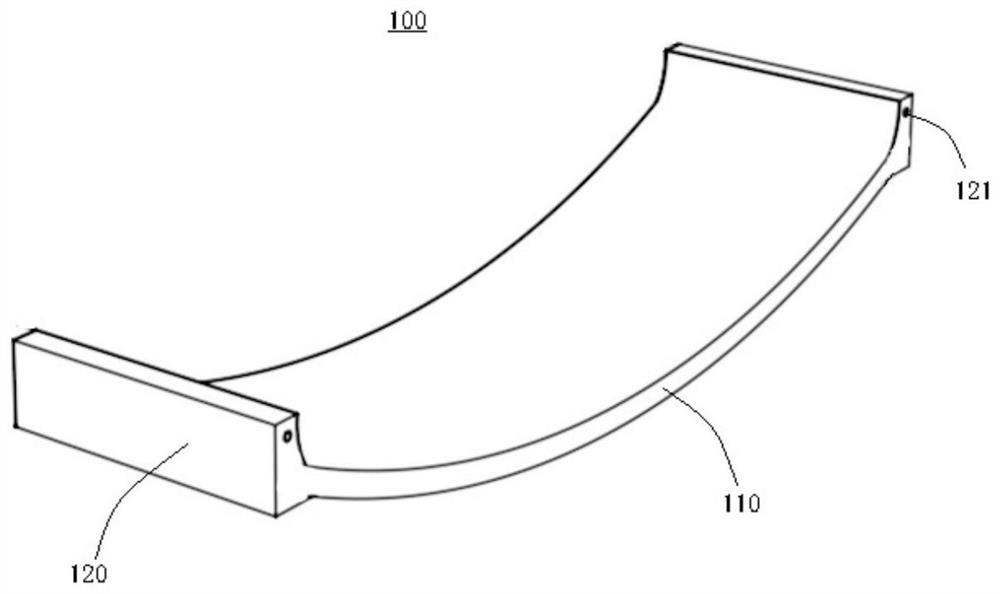

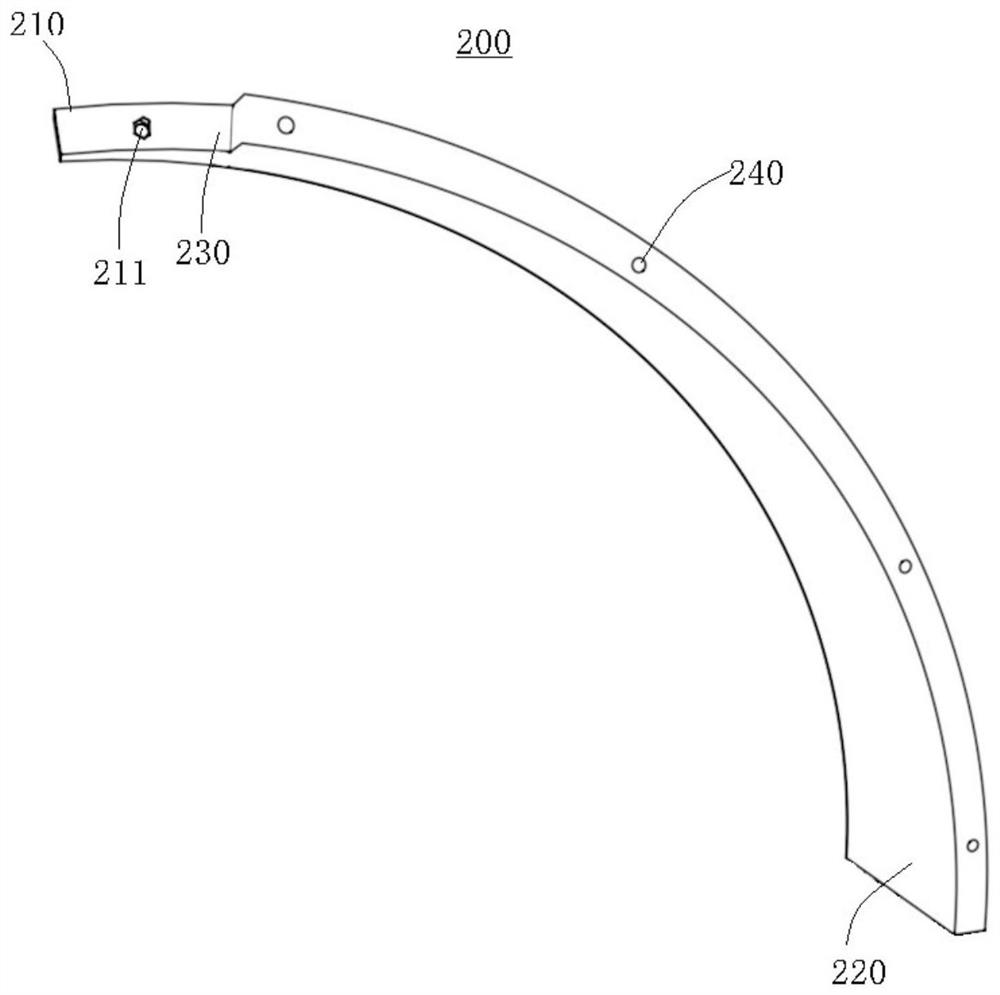

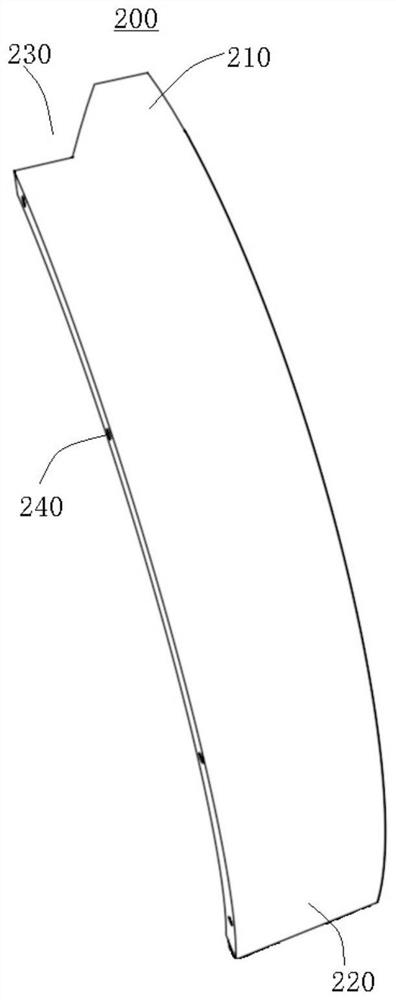

[0062] This embodiment provides a prefabricated tunnel structure, which can be used for the construction of the second lining after the completion of the initial support and waterproof layer of the new tunnel and the repair of the inner arch of the damaged second lining of the existing tunnel. The fabricated tunnel structure includes a plurality of bottom linings 100, a first arch lining 200, a second arch lining 300 and a third arch lining 400. A plurality of bottom liners 100 are sequentially connected along the first direction. The bottom of the first arch lining 200 is connected to the bottom lining 100 , and the first arch lining 200 is formed with a first matching portion 230 . The bottoms of the plurality of second arch linings 300 are connected to the bottom lining 100 , and the second arch linings 300 are formed with second matching portions 311 . The second matching part 311 is used to cooperate with the first matching part 230, and the second matching part 311 of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com