An air compressor oil and gas waste heat recycling device

An air compressor, oil and gas technology, applied in the direction of mechanical equipment, machines/engines, liquid displacement machinery, etc., can solve the problem of easy accumulation of oil and achieve good oil discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

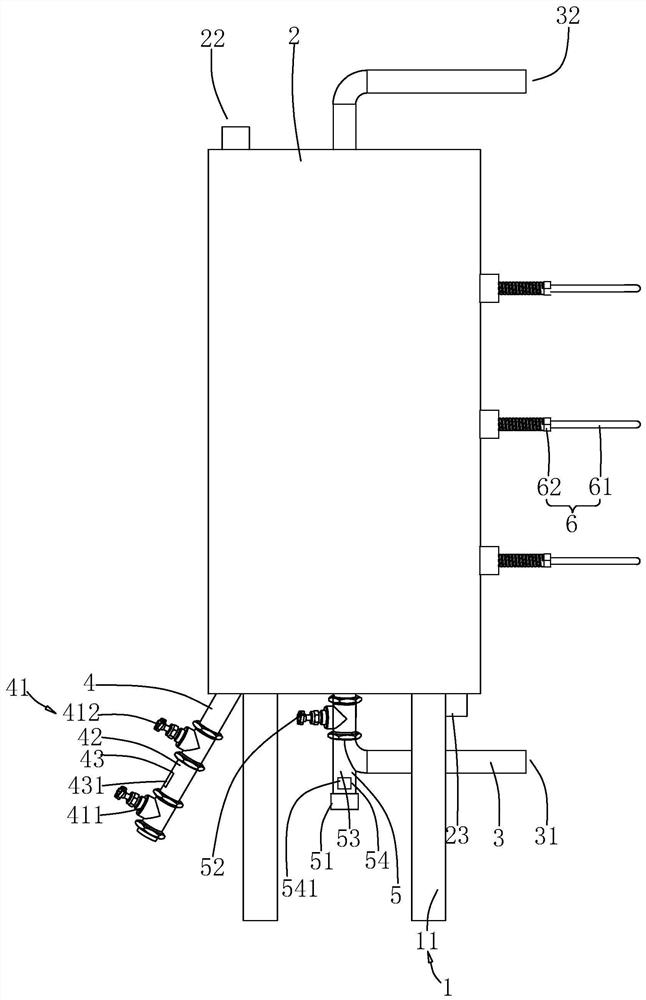

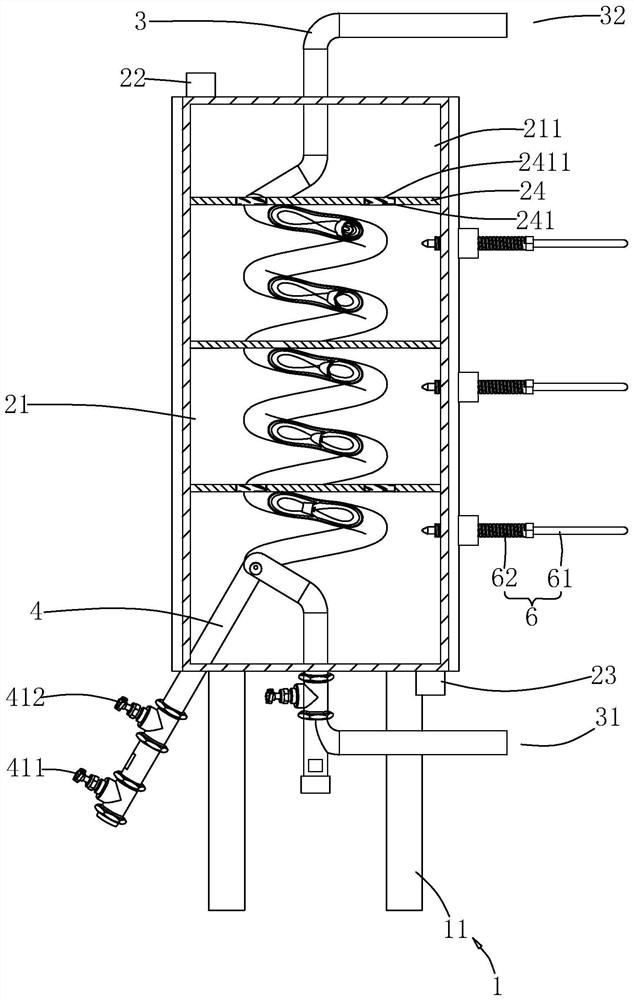

[0039] Attached to the following Figure 1-3 This application will be described in further detail.

[0040] The embodiment of the present application discloses a device for reusing oil and gas waste heat of an air compressor. refer to figure 1 , including the bracket 1, the water tank 2 and the ventilation pipe 3. The ventilation pipe 3 is placed in the water passing tank 2 , two ends of the ventilation pipe 3 respectively extend out of the water passing tank 2 , and the ventilation pipe 3 and the water passing tank 2 are fixedly connected. One end of the ventilation pipe 3 is an air inlet 31 , and the other end of the ventilation pipe 3 is an air outlet 32 .

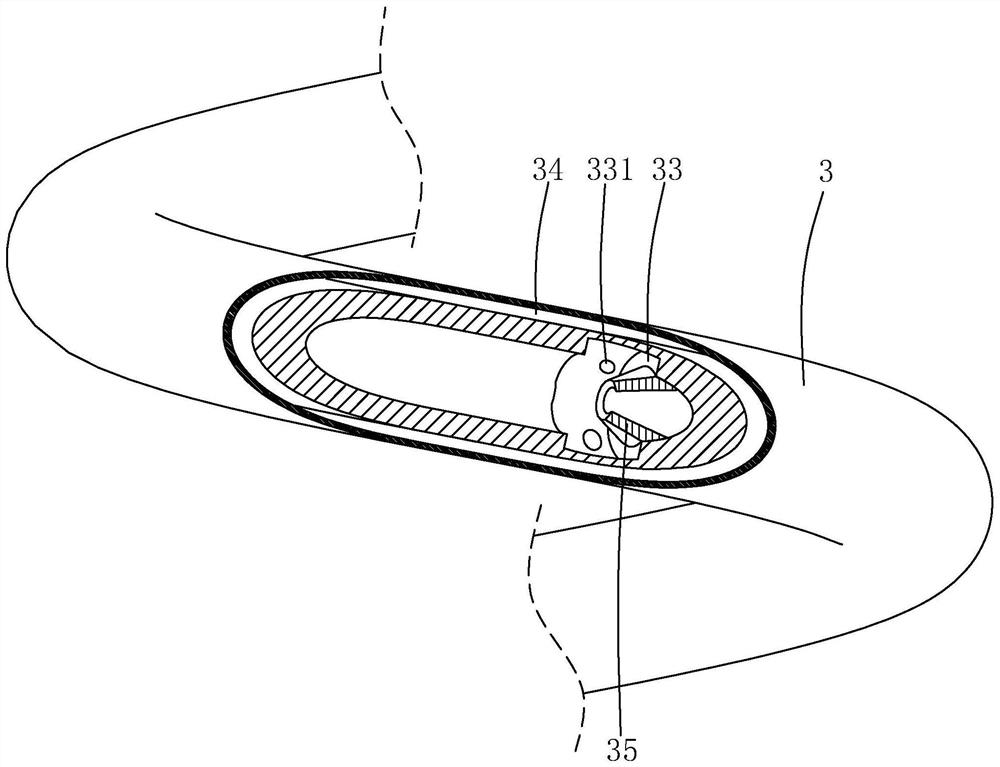

[0041] refer to figure 2 , the outer surface of the ventilation pipe 3 and the inner surface of the water tank 2 form a water passage cavity 21 .

[0042] The water passage tank 2 is supported on the ground by a bracket 1 , and the bracket 1 includes four outriggers 11 , which are all fixed to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com