Molten salt pump complete device with in-tank under-pressure design

A complete set of equipment, molten salt pump technology, applied to pump equipment, parts of pumping equipment for elastic fluids, pressure pumps, etc., can solve the problems of large volume, inconvenient maintenance and expensive cost, etc., to improve reliability Sex and service life, simple structure, and the effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below.

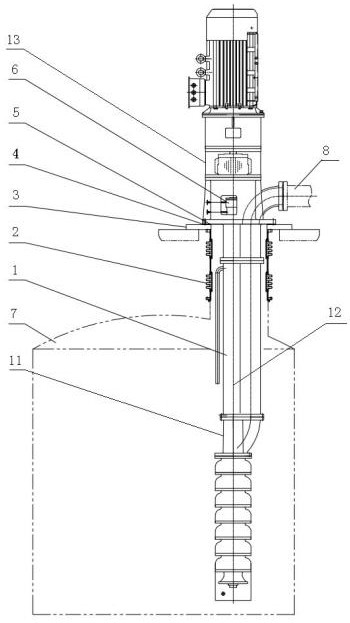

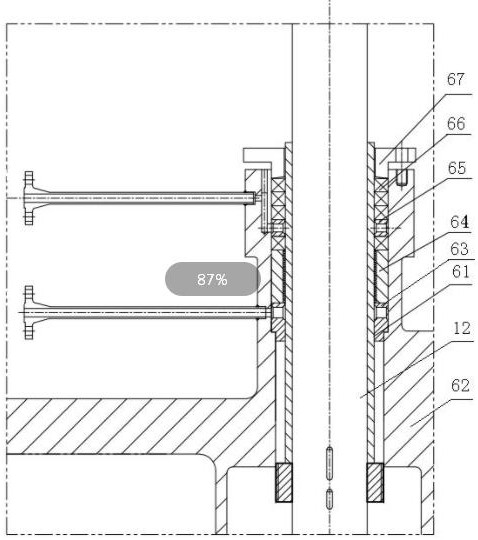

[0019] Referring to the accompanying drawings, a complete set of molten salt pump designed under pressure in the tank includes a high-temperature molten salt pump 1 and a molten salt tank under pressure 7. The high-temperature molten salt pump 1 includes a pump body 13, a pump shaft 12, and a pump shaft Connecting pipe 11, the pump body 13 is connected to the pump shaft connecting pipe 11, the pump shaft 12 is arranged inside the pump body 13 and the pump shaft connecting pipe 11, and it is characterized in that: the lower part of the high temperature molten salt pump 1 extends into the In the molten salt tank 7, a sealing bellows 2 is provided at the joint between the opening of the molten salt tank 7 under pressure and the pump bottom plate 3, and a heat insulating pad 4 is provided between the upper end surface of the pump bottom plate 3 and the pump body 1, A bottom plate seal 5 is provided between the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com