Stepping motor

A stepping motor and stator technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of high output torque requirements and limited motor installation space, and achieve the effect of increasing output torque, reducing height and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

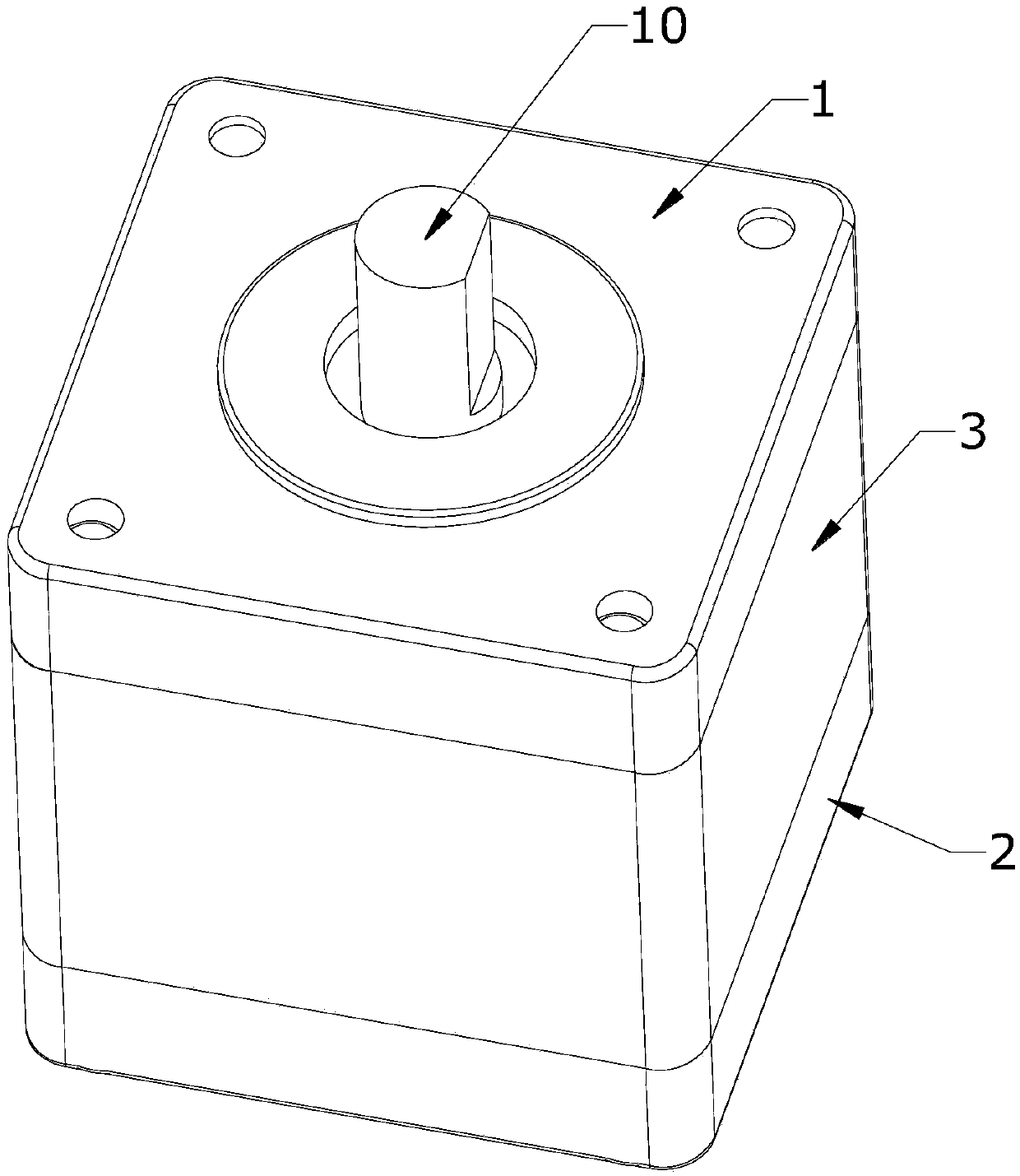

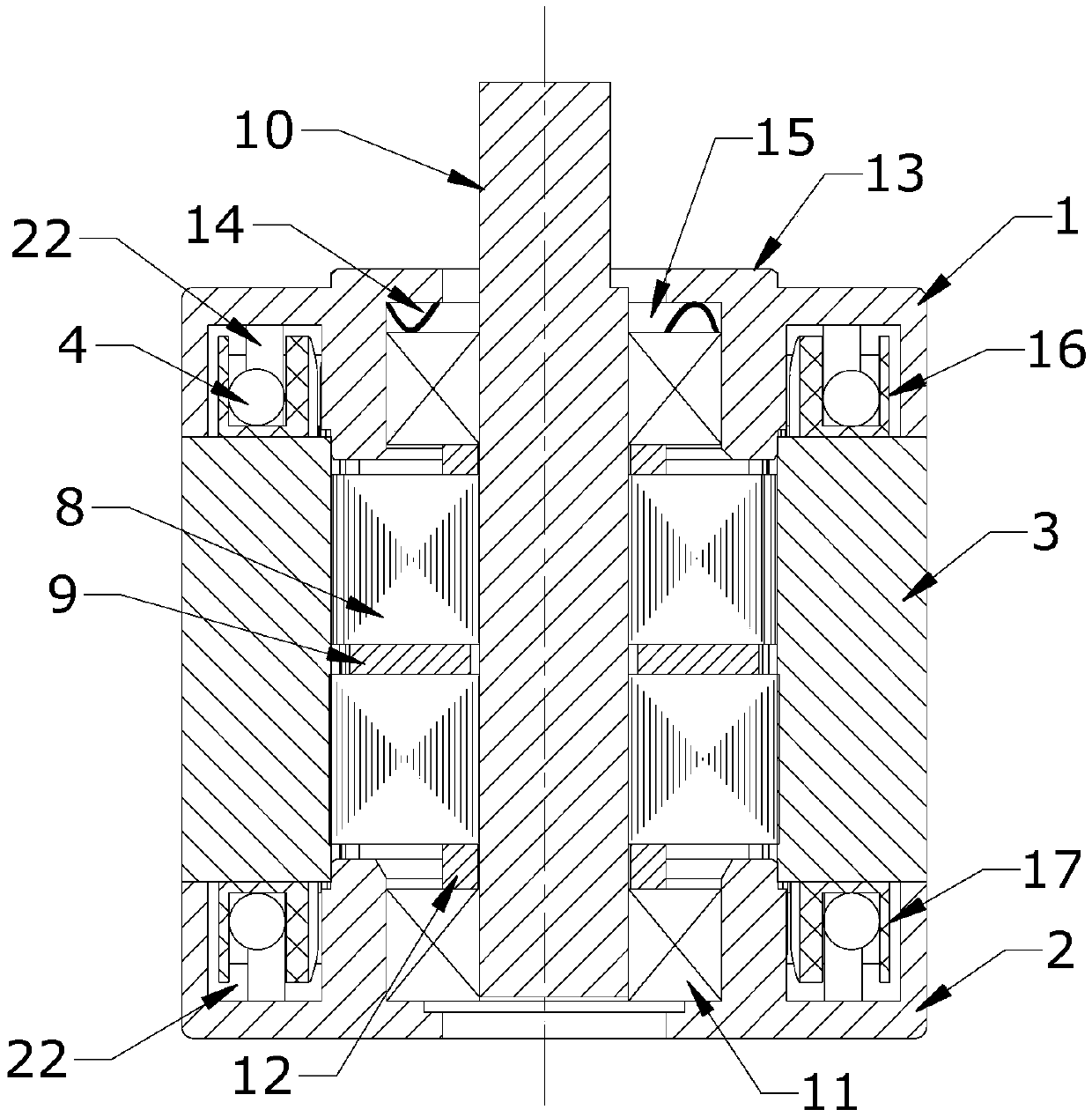

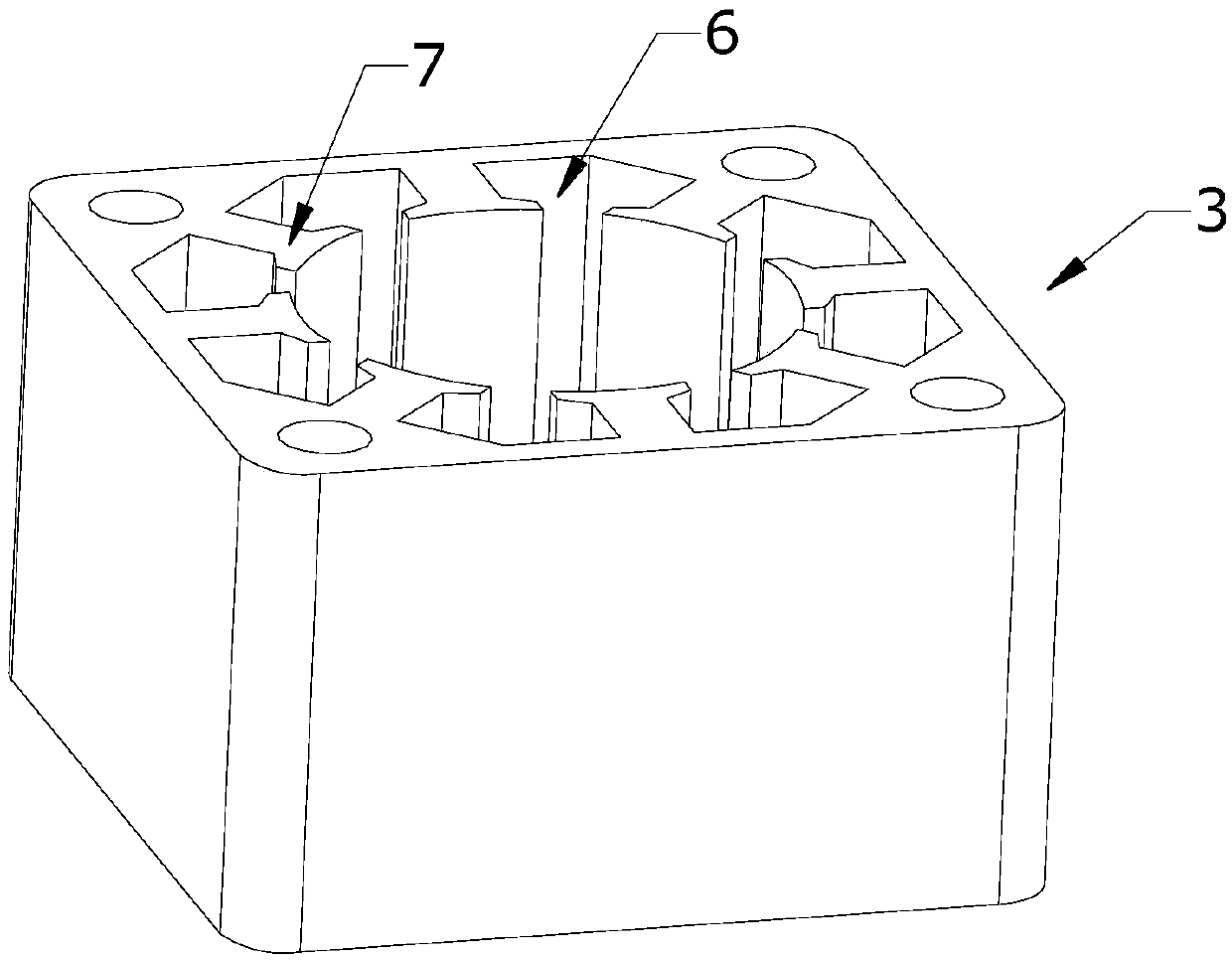

[0034] see figure 1 , figure 2 , The structure of the stepper motor in this embodiment includes a stator 3 assembly, a rotor assembly, a front end cover 1, and a rear end cover 2.

[0035] The stator 3 assembly includes a stator 3, an enameled wire 4, and an insulating end cover with legs 5 embedded in the winding slot 6 of the stator 3; the enameled wire 4 is wound on the insulating end cover to form a winding group for each magnetic pole 7 of the stator 3.

[0036] The rotor assembly includes a rotor piece 8, a magnetic steel 9, and a rotating shaft 10; the two ends of the rotating shaft 10 are respectively supported by the bearing 11 installed in the bearing 11 chamber of the front end cover 1, and the bearing 11 of the bearing 11 chamber of the rear end cover 2 . In this embodiment, the rotor assembly further includes a bushing 12 sleeved on the rotating shaft 10 and located between the bearing 11 and the rotor piece 8 . Since in this embodiment, the number of the roto...

Embodiment 2

[0043] Figure 6 , Figure 7 Shown is another embodiment of the stepper motor of the present invention. The stepping motor includes a stator 3 assembly, a rotor assembly, a front end cover 1 and a rear end cover 2 . In this embodiment, the structures of the stator 3 assembly, the rotor assembly, and the rear end cover 2 are exactly the same as those of the stepper motor in the embodiment, and will not be described in detail here.

[0044] In this embodiment, the front end cover 1 is basically the same as the front end cover 1 of the stepping motor in the embodiment, the difference is that the front end cover 1 is also provided with two opposite mounting ears 23, opposite to each other. Figure 6 Viewing angle, the two mounting ears 23 are respectively located on the left and right sides of the front cover 1 , and the mounting ears 23 are provided with screw holes 24 . The mounting holes of the front cover 1 of general stepping motors are common to the screw holes for fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com