Power-assisted steering oil cylinder with stroke unloading valve

A technology of steering power cylinder and unloading valve, which is applied in the field of power cylinders and can solve the problems of short service life and low stability of the limit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

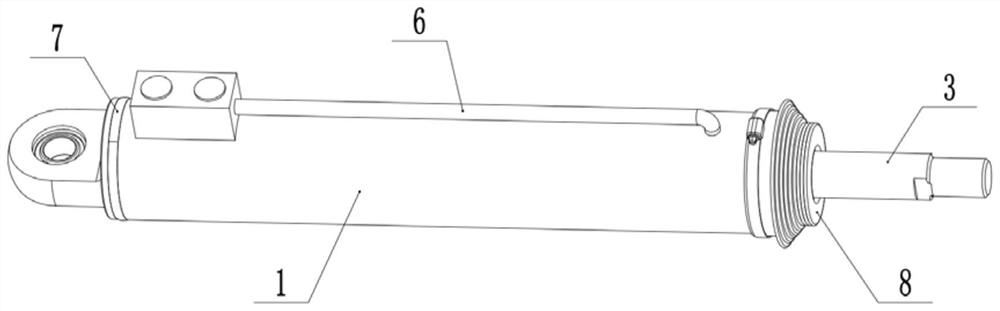

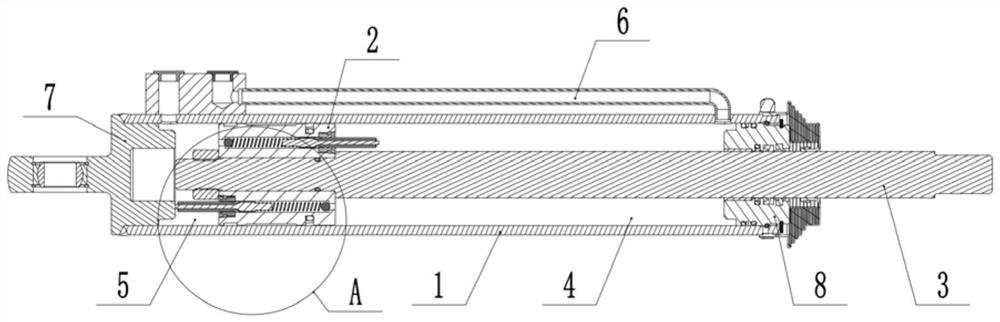

[0035] Embodiment one is basically as attached figure 1 with figure 2 Shown: the power steering cylinder with a stroke unloading valve, including a cylinder body 1 and a piston 2 that is slidably connected in the cylinder body 1. The piston rod 3 and the piston 2 divide the cylinder 1 into a rod chamber 4 and a rodless chamber 5. Two oil pipes 6 are connected to the cylinder body 1, and the two oil pipes 6 communicate with the rod chamber 4 and the rodless chamber 5 respectively. , the oil pipe 6 can be used to feed high-pressure hydraulic oil into the rod chamber 4 or the rodless chamber 5; at the same time, the left end and the right end of the cylinder body 1 are fixedly connected with end caps through threads, and for the convenience of distinction, the left end cap is The left end cap 7, the right end cap is the right end cap 8.

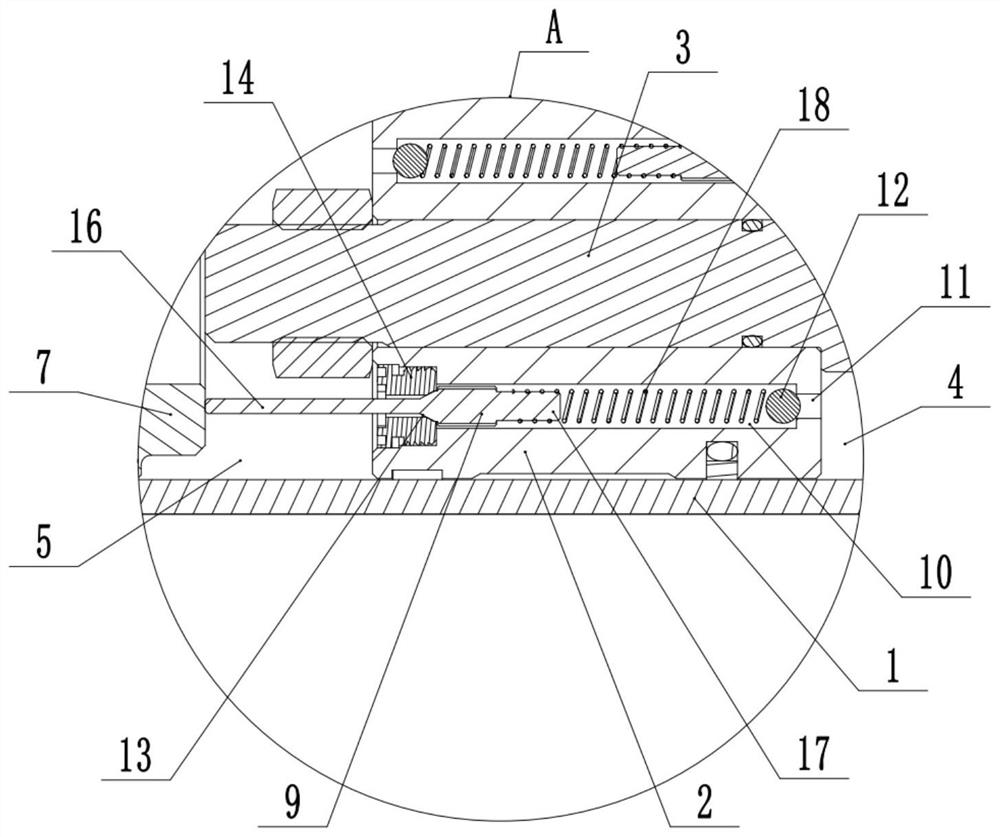

[0036] combine figure 2 with image 3 The piston 2 is provided with at least two flow passages respectively communicating with the rod ch...

Embodiment 2

[0045] The difference between embodiment two and embodiment one is: as Figure 5 As shown, the large-diameter section 10 is connected with a horizontally arranged slide bar 19 through an interference fit. The slide bar 19 is coaxially arranged with the push rod 16 and the right end of the push rod 16 is located in the slide bar 19. The left end of the slide bar 19 Extend outside the left side of piston 2, and the left end of push rod 16 extends outside the left end of slide rod 19; A communication gap is formed between the outer walls of the push rods 16, and the inner hole of the slide rod 19 is provided with a second mating inclined surface near the right end to the sealing inclined surface 13 at the left end of the control rod 9.

[0046] When the second mating inclined surface is in contact with the sealing inclined surface 13, the hydraulic oil at the position of the support spring 18 in the large-diameter section 10 cannot flow to the left through the communication groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com