Tire curing bladder leakage detection method

A technology for tire vulcanization and leak detection, which is applied in the direction of measuring the acceleration and deceleration rate of fluids and using liquid/vacuum for liquid tightness measurement. It can solve the problems of easy damage, economic loss, continuous waste, etc. Accuracy, reduce economic losses, avoid the effect of continuous scrap

Pending Publication Date: 2022-02-25

SAILUN GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the capsule is prone to damage during actual use. Once the capsule leaks, the internal medium fluid will leak between the capsule and the embryo, which is difficult to be found, resulting in continuous waste products in subsequent production, causing serious economic losses.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

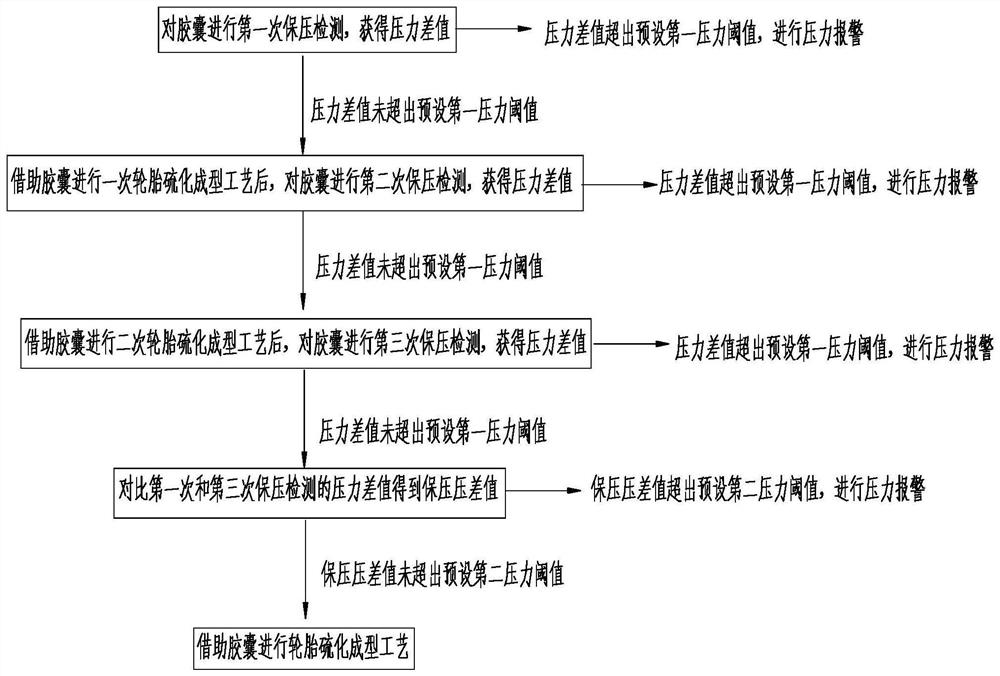

[0030] Such as figure 1 As shown, a tire vulcanized capsule leak detection method, including the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

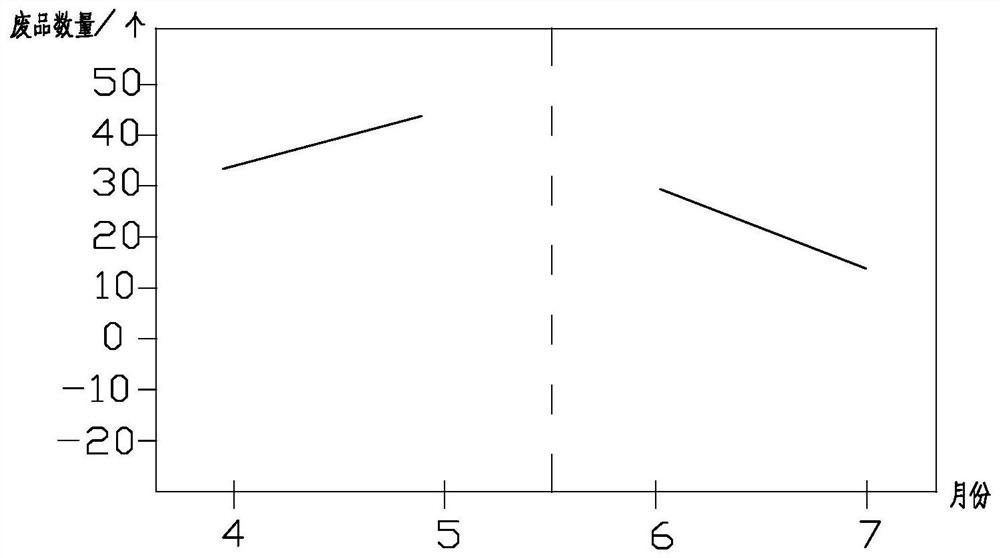

The invention relates to a tire curing bladder leakage detection method, and belongs to the technical field of tire production and processing, a pressure difference value is calculated for each time of pressure maintaining detection, and if the pressure difference value exceeds a preset first pressure threshold value, pressure alarm is carried out to realize detection of bladder rupture leakage, therefore, the phenomenon of continuous waste caused by capsule breakage is avoided, economic losses are reduced, meanwhile, second-time pressure maintaining detection is conducted at intervals, the pressure difference value of the first-time pressure maintaining detection and the pressure difference value of the third-time pressure maintaining detection are taken to calculate the pressure maintaining pressure difference value, if the pressure maintaining pressure difference value exceeds a preset second pressure threshold value, pressure alarming is conducted, and when the capsule leaks slightly, the phenomenon that whether the capsule leaks or not cannot be judged through the pressure difference value of each time of pressure maintaining detection is avoided, and the detection precision is improved.

Description

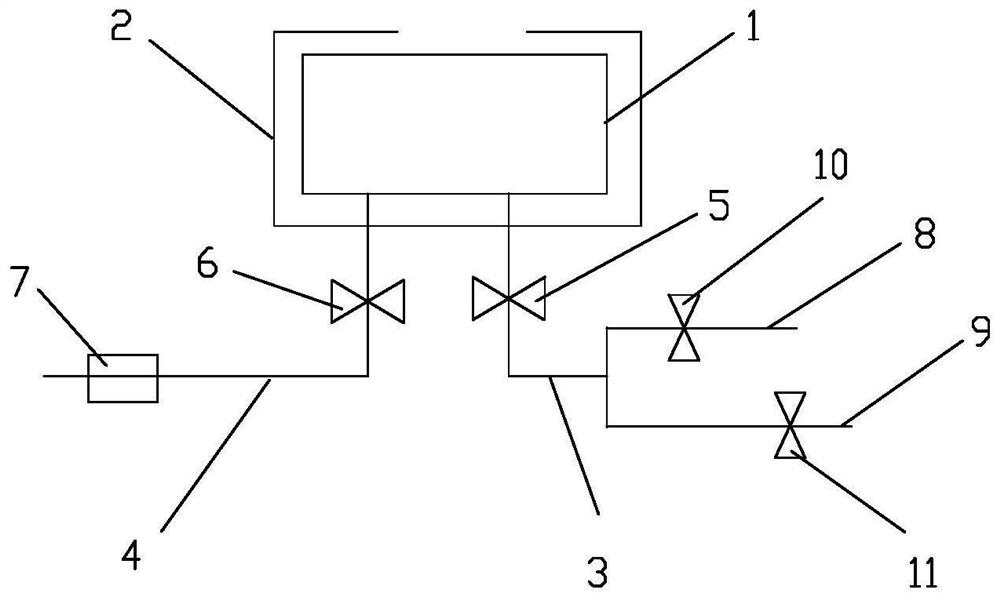

Technical field [0001] The present invention belongs to the field of tire production and processing, and in particular, to a leak detection method for tire vulcanization capsules. Background technique [0002] Tire sulfurized capsules (referred to as capsules) is a hollow thin-walled rubber article, during the vulcanization molding process of tires, mounted inside the tire vulcanizing machine as a tire stereotype. Inside the capsules, the capsule is filled into fluid media such as overheating water or compressed air, so that the capsule is extended to the tire embryo, which is combined with the tire fetal, using the flow heat transfer characteristics of the internal fluid medium in the capsule, and maintains the temperature in the tire vulcanization. Balanced, achieving a uniform effect of tires, and improves the balance of tires. However, the capsule is prone to damage during the actual use. Once the capsule leaks, the internal medium fluid will leak between the capsule and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M3/32

CPCG01M3/32

Inventor 刘晓庆李鲁刚高勇

Owner SAILUN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com