Battery module test safety protection device

A technology of safety protection device and battery module, which is applied in the direction of secondary battery testing, engineering safety device, measuring device, etc. It can solve the problems of endangering the safety of workers, module safety, failure to guarantee power failure and gas failure, etc., so as to avoid errors touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

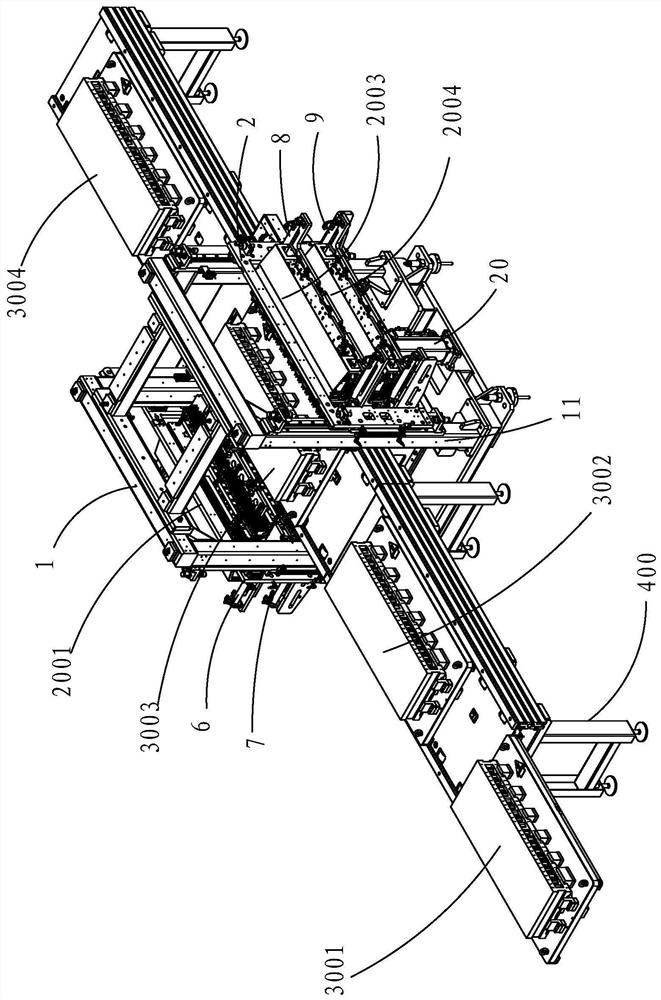

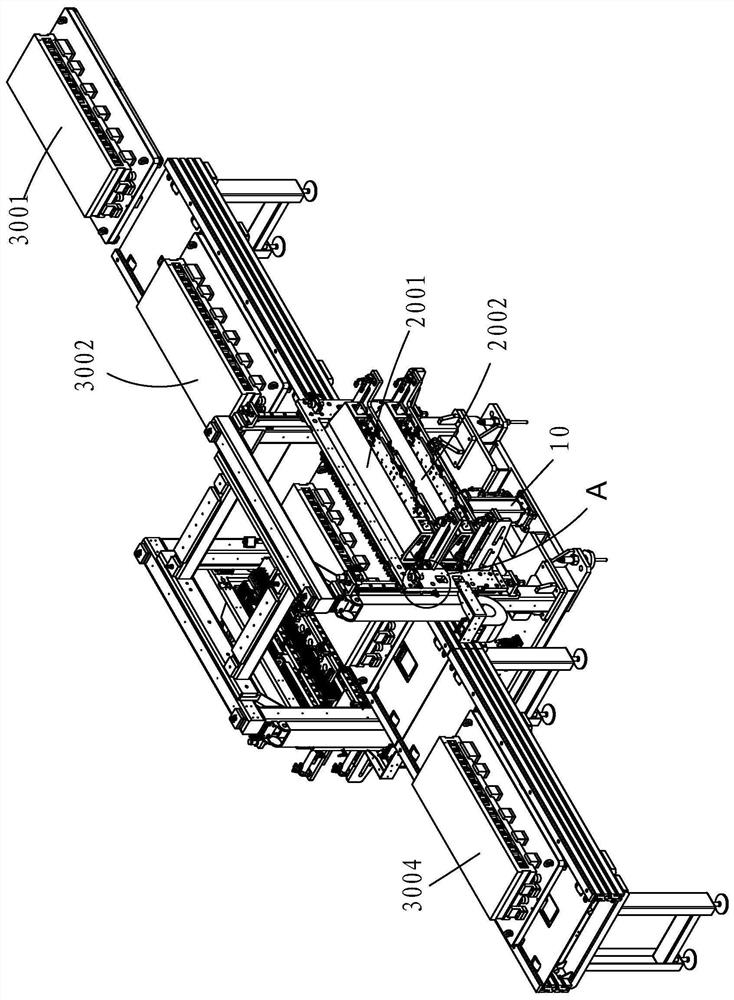

[0155] A safety protection device for battery module testing, comprising:

[0156] The gantry frame 1 includes four uprights 11 arranged in a rectangle, each of the outer sides of the uprights 11 is fixedly connected with an anti-falling block 12, and the outer side of the anti-falling block 12 is provided with a first bolt hole 121; In a specific embodiment, the battery module is transported by the conveying line 400, and the conveying line 400 is erected in the gantry frame 1 and located between the two vertical support frames 2;

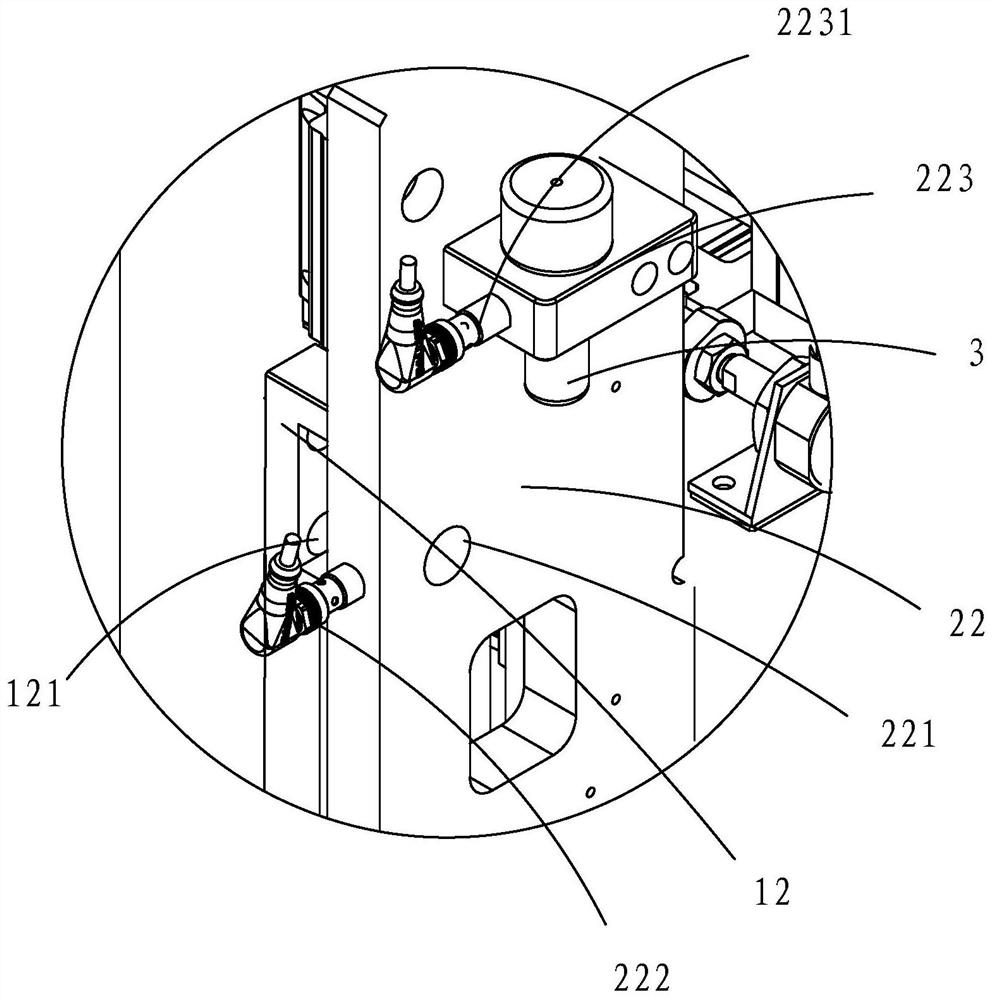

[0157] There are two vertical support frames 2, which are symmetrically arranged, and respectively include a transverse connecting plate 21 and two vertical slide plates 22; each of the vertical slide plates 22 is provided with a second pin hole 221; The vertical sliding plate 22 is symmetrically and fixedly connected to the transverse connecting plate 21; the vertical sliding plate 22 is vertically slidingly connected to the column 11 one by one,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com