Device and method for remote joint test of electronic equipment

An electronic device and remote technology, applied in the electronic field, can solve the problems of difficult site adjustment, high cost, and different distances, and achieve the effects of shortening the work cycle, improving work efficiency, and ensuring phase noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

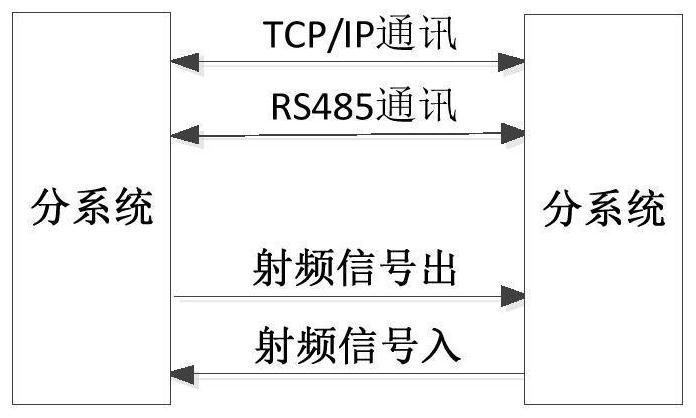

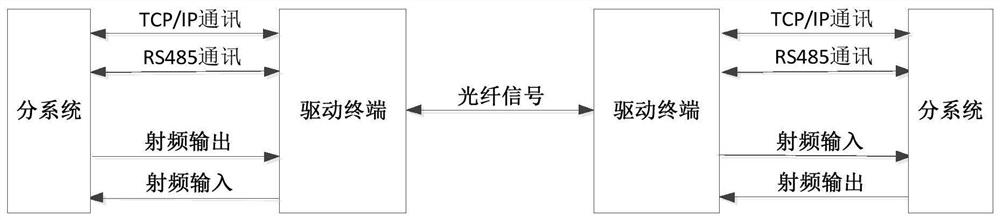

[0035] Embodiment 1: as figure 1 As shown, a device for remote joint testing of electronic equipment is composed of multiple drive terminals connected to each other through optical fibers. At least one drive terminal is installed at each subsystem participating in the system joint test to connect the communication and radio frequency signals of the subsystems. After the drive terminal converts these signals into optical signals, they are combined on an optical fiber and transmitted to another drive terminal in the distance. The drive terminal converts the optical signals into corresponding radio frequency and communication signals, and Cross-linking with distant subsystems, such as figure 2 shown.

Embodiment 2

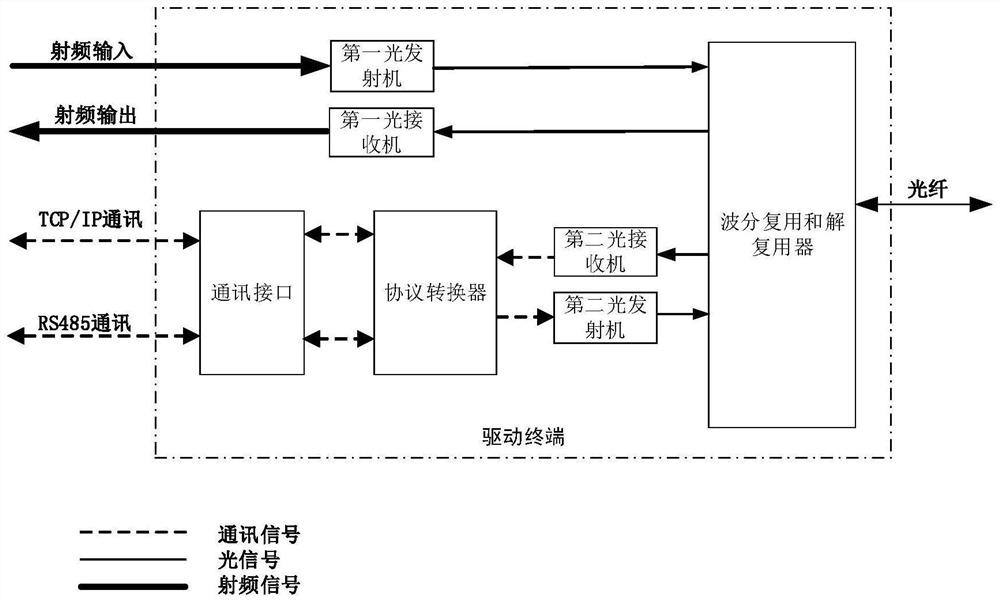

[0036] Embodiment 2: On the basis of Embodiment 1, in specific applications, the drive terminal is provided with one RS485 protocol communication interface, one TCP / IP protocol communication interface, one radio frequency signal output, and one radio frequency signal input. During implementation, the communication protocol is not limited to this, it can be other communication protocols with a bandwidth not greater than 200Mbps, and the number of interfaces is not limited to this. The composition of the drive terminal is as follows image 3 Schematically, the working principle is as follows:

[0037] The first optical transmitter and the first optical receiver, in the first optical transmitter, the carrier optical signal is first generated by the laser, and then the input electrical signal is modulated onto the carrier optical signal and output; the first optical receiver converts the input optical signal The modulated electrical signal in the signal is demodulated and output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com