Method for analyzing copolycarbonate

A technology of copolycarbonate and polysiloxane, which is applied in separation methods, analytical materials, chemical instruments and methods, etc., can solve the problems of inability to determine the molecular weight of polysiloxane, inability to determine the molecular weight distribution of polysiloxane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

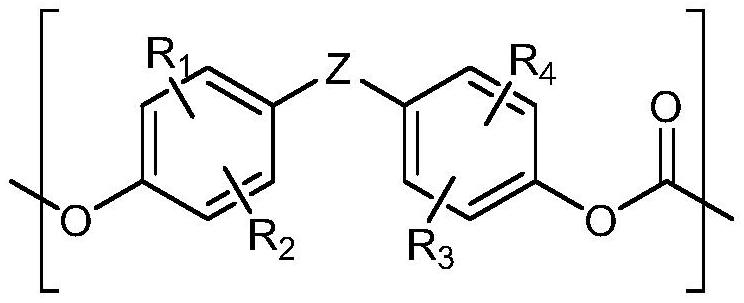

[0124] A copolycarbonate comprising a first repeating unit of bisphenol A (BPA) from LG Chem, Ltd. and a second repeating unit from a polysiloxane-containing aromatic diol compound having the following structural formula (based on The total weight of the copolycarbonate contains 7% by weight of polysiloxane-containing aromatic diol compound).

[0125] The polysiloxane-containing aromatic diol compound used as a starting material below had a weight average molecular weight of 4,830 g / mol, a number average molecular weight of 3,300 g / mol, and a molecular weight distribution (Mw / Mn) of 1.47.

[0126]

preparation Embodiment 2

[0128] Copolycarbonate FG1700 of Idemitsu Co. comprising a repeating unit derived from a polysiloxane-containing aromatic diol compound was prepared.

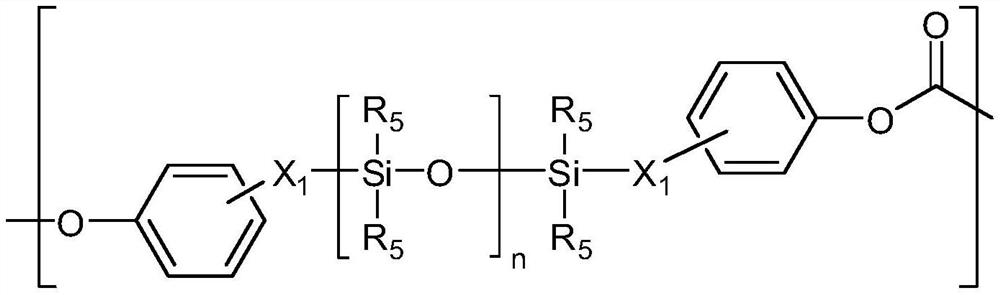

[0129]

preparation Embodiment 3

[0131] Sabic Corp.'s copolycarbonate EXL1414 comprising repeating units derived from a polysiloxane-containing aromatic diol compound was prepared.

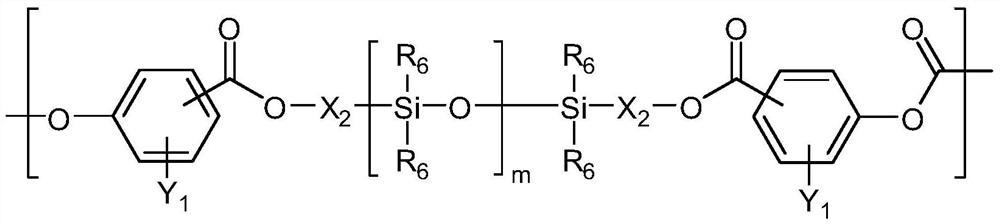

[0132]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com