Automatic rubber tapping machine

A rubber machine and automatic technology, applied in forestry, application, agriculture, etc., can solve the problems of cutting the rubber tree body, breaking the blade, and the blade has no structure to limit the amount of knots, and achieve the effect of avoiding waste and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

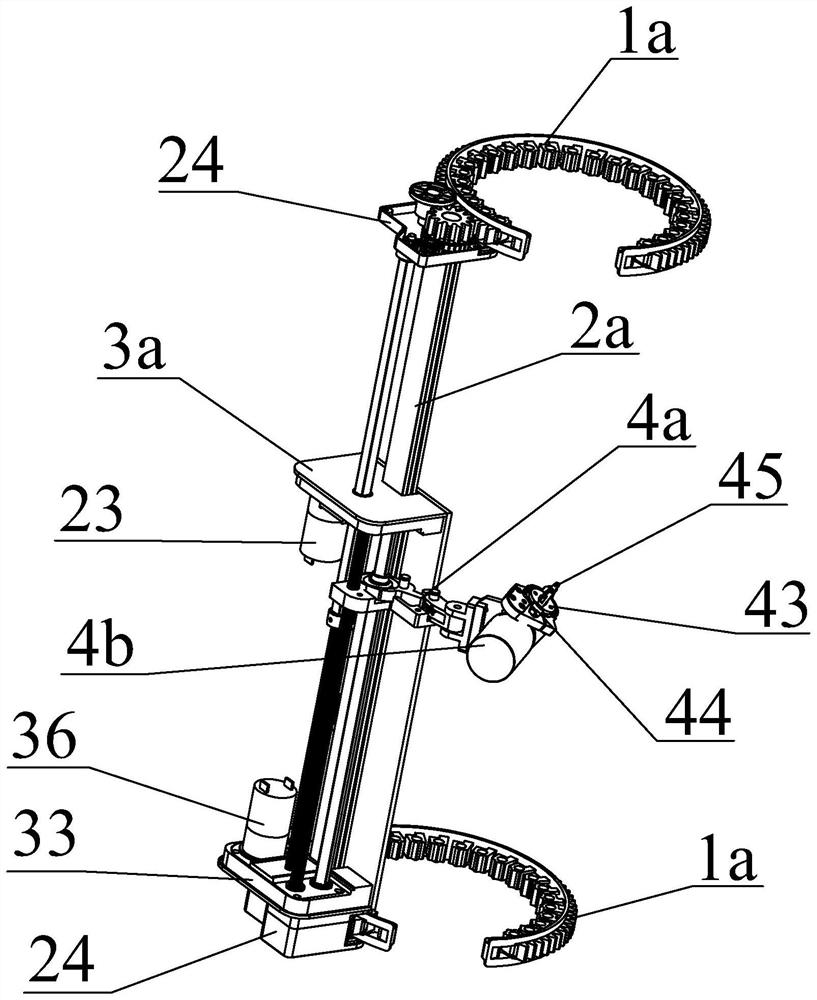

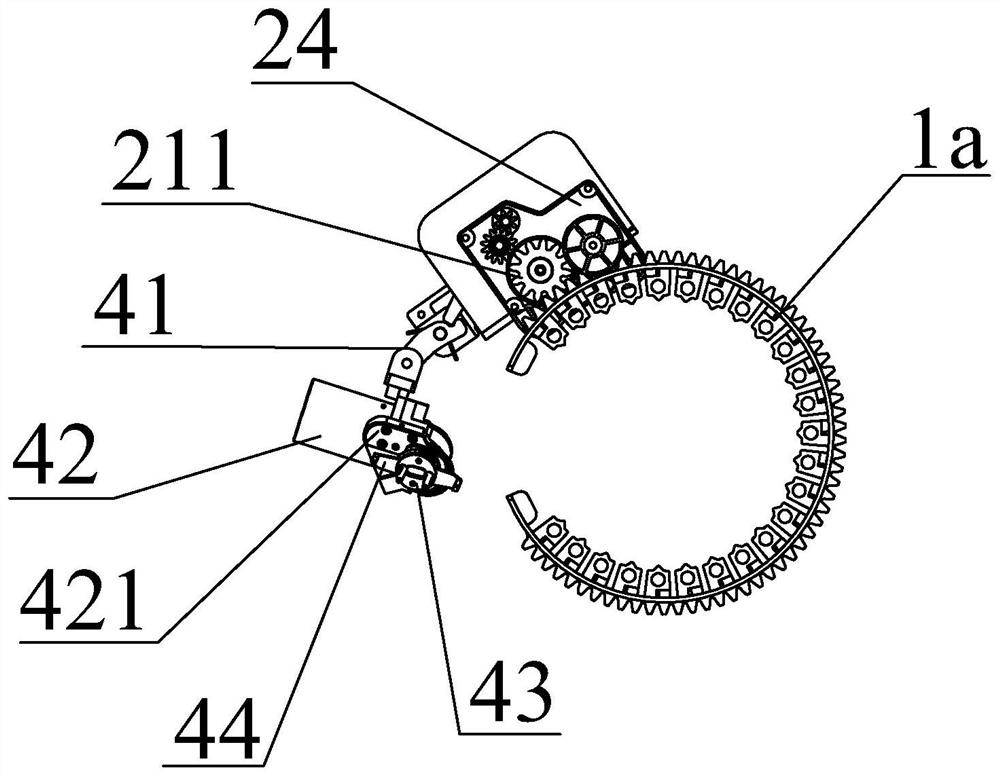

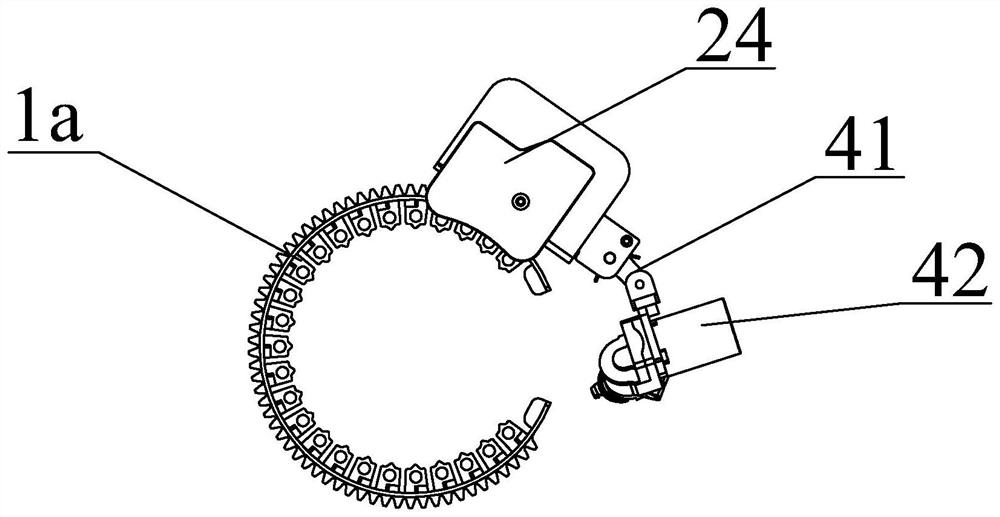

[0046] refer to Figure 1 to Figure 5 As shown, in this embodiment, the cutter module 4a includes a liftable and swingable knife adjustment bracket 41, the electric mechanism 4b includes a rubber tapping motor 42 and a rotary cutter head 43 linked with the rubber tapping motor 42, and the rubber tapping motor 42 is positioned at the adjustment position. On the knife support 41, the rotary cutter 44 is fixed on the rotary cutter head 43.

[0047] The cutting knife module 4 a also includes an arc-shaped positioning ring 422 , through which the cutting amount of the cutting edge of the rotary cutting knife 44 is limited. There are at least two rotary cutters 44 , which are evenly arranged on the edge of the rotary cutter head 43 .

[0048] The rubber tapping motor 42 is provided with an adjustment disc 421, and the positioning ring 422 is positioned on the adjustment disc 421 to adjust its positioning angle and the feed rate of the knife edge.

[0049] Adjustment plate 421 is p...

no. 2 approach

[0053] refer to Figure 1 to Figure 9 As shown, in this embodiment, the outer arc wall of the arc guide rail 1a body is provided with outer ring teeth 11 , the inner arc wall is provided with inner ring teeth 12 , and the arc guide rail 1a is provided with locking connectors 14 .

[0054] An annular channel 13 is provided along the arc-shaped guide rail 1a, and the locking connector 14 is a band, which is inserted in the annular channel 13 . Wherein, the locking connector 14 includes but is not limited to a strap, a cable tie throat hoop, etc., which can be selected and used according to specific situations.

[0055] In this embodiment, the arc-shaped guide rail 1a can be deformed, and can be more conveniently embraced on the tree trunk, wherein it is locked and fixed by the locking connector 14, so that the moving frame 2a can move stably between the upper and lower arc-shaped guide rails 1a . The outer ring teeth 11 and the inner ring teeth 12 have a tooth pattern structur...

no. 3 approach

[0057] refer to Figure 1 to Figure 13 As shown, in this embodiment, the moving frame 2a includes a linear guide rail 21, a linkage rod 22, a drive motor 23 and a walking seat 24 located at both ends of the linear guide rail 21, and the two ends of the linkage rod 22 pass through the travel gear 211 and the arc. The outer ring teeth 11 of the guide rail 1a are meshed and connected, and the driving motor 23 is arranged on the traveling seat 24 or the lifting module 3a to drive the linkage rod 22 to rotate.

[0058]Wherein when the drive motor 23 is located on the travel seat 24, it is directly meshed with the travel gear 211 through a gear structure to drive the travel gear 211 to rotate, and the travel gear 211 walks on the outer ring teeth 11 during rotation to drive the travel seat 24 moves on the arc guide rail 1a. When the drive motor 23 is arranged on the lifting module 3a, the drive motor 23 can be engaged by gears by driving the linkage rod 22 to rotate, and the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com