Spraying, heating and atomizing device for spraying ammonia water for denitration

A heating atomization and denitrification technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of increased use cost, excessive spraying of atomizers, easy loss, etc., to achieve convenient installation and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

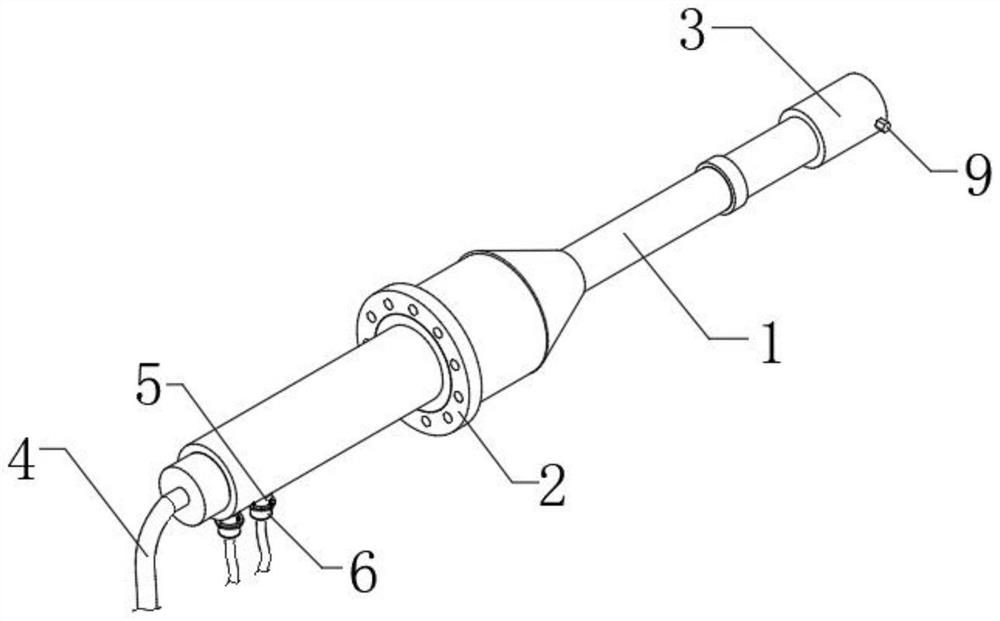

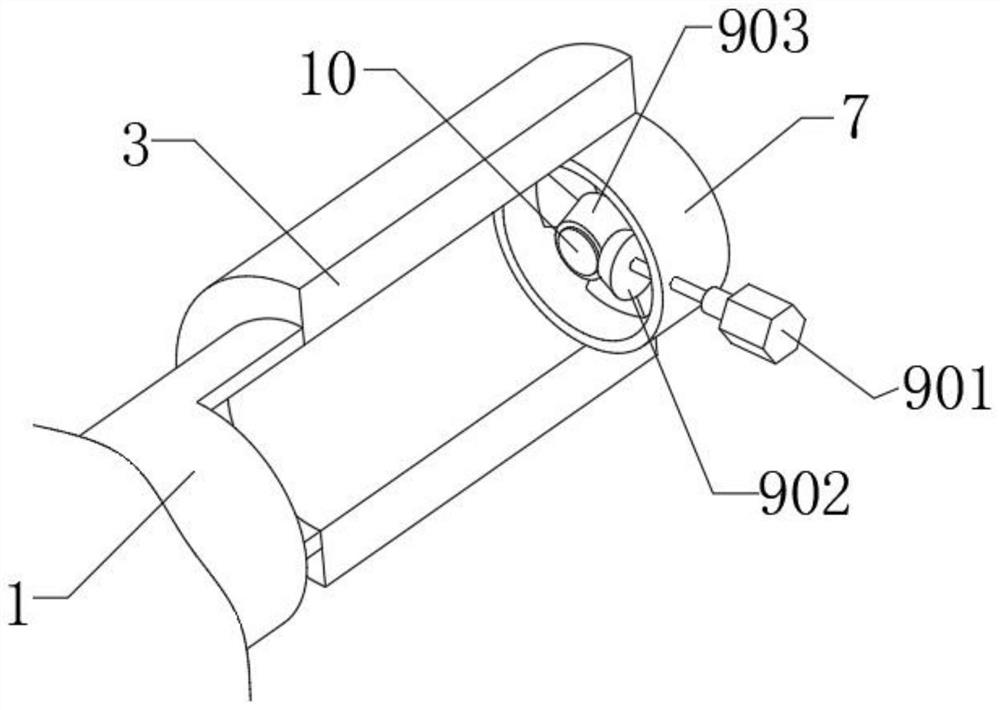

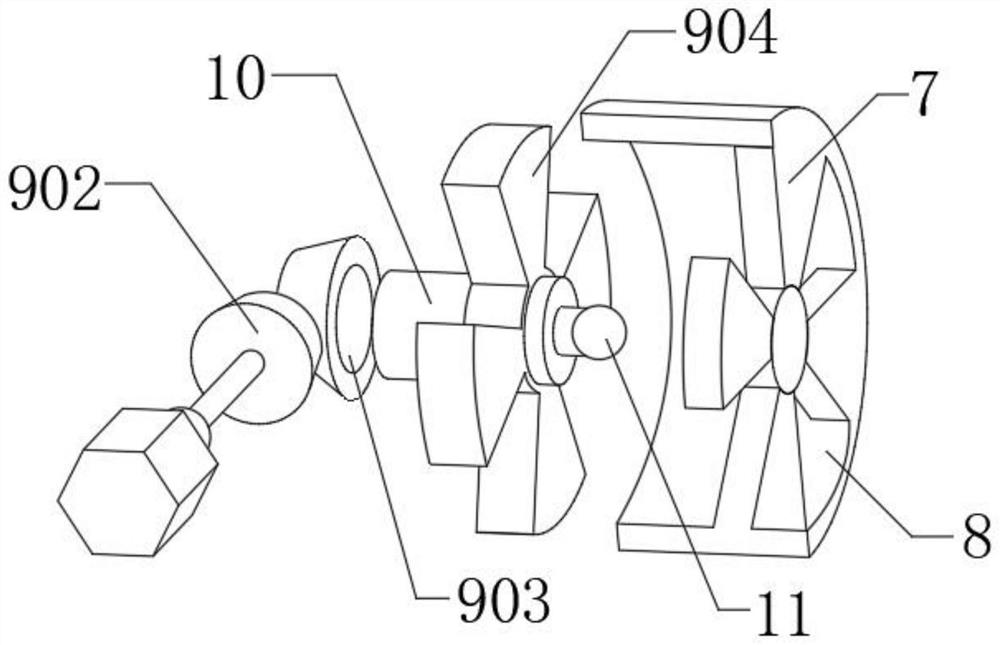

[0033] The embodiment of the present invention discloses a spray heating atomization device for spraying ammonia water for denitrification, such as Figure 1-8 As shown, it includes a denitrification spray gun 1, one end of the denitrification spray gun 1 is equipped with an atomizing nozzle 3, the outer surface of the denitrification spray gun 1 is fixedly installed with a fixed plate 2, one end of the denitrification spray gun 1 is equipped with a first connecting pipe 4, and the denitrification spray gun 1 is away from The lower surface of one end of the atomizing nozzle 3 is fixedly installed with a first connector 5, and the lower surface of the first connector 5 is movably connected with a second connector 6, and one end of the second connector 6 is equipped with a second connecting pipe 401. A connecting head 5 , a second connecting head 6 and a second connecting pipe 401 can pour the reducing agent into the interior of the denitration spray gun 1 , and then spray the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com