A construction waste crushing device with dust removal function

A construction waste and crushing device technology, which is applied in construction waste recycling, dust removal, transportation and packaging, etc., can solve the problems of environmental damage, dust flying, poor practicability, etc., to prevent dry pumping, improve crushing efficiency, and improve practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

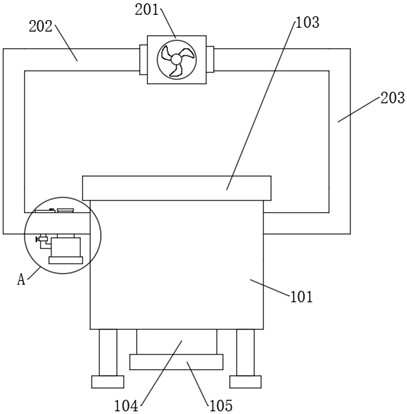

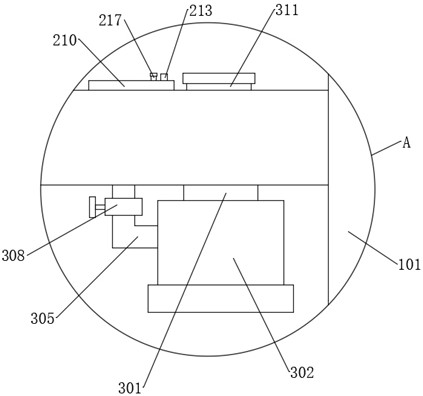

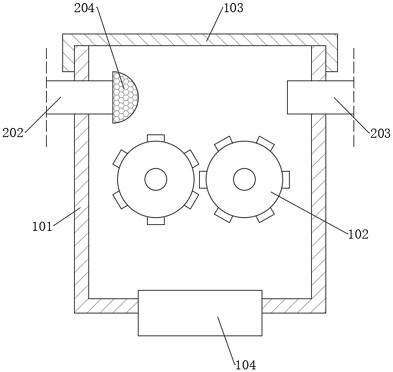

[0046] see Figure 1-Figure 10 , a construction waste crushing device with dust removal function, comprising a crushing box 101, two crushing rollers 102 provided with a driving mechanism are installed in the crushing box 101, the top of the crushing box 101 is set in an open shape, and the top of the crushing box 101 is set The sealing box cover 103 matched with it, the bottom outer wall of the crushing box 101 is communicated with the discharge cylinder 104, and the bottom end of the discharge cylinder 104 is provided with a matching sealing cylinder cover 105. After the crushing is completed, unscrew the seal The canister cover 105 can discharge the pulverized waste through the discharge cylinder 104. The gas circulation pump 201 is fixedly installed above the crushing box 101. The suction end of the gas circulation pump 201 is connected to the suction pipe 202, and the gas circulation pump 201 is exhausted. One end of the exhaust pipe 202 and the end of the exhaust pipe 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com