Coating machine capable of intelligently regulating and controlling temperature

A technology for controlling temperature and coating machine, which is used in devices for coating liquid on the surface, devices for making medicines into special physical or taking forms, coatings, etc. The thickness of the tablet coating varies, so as to ensure the integrity and improve the uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

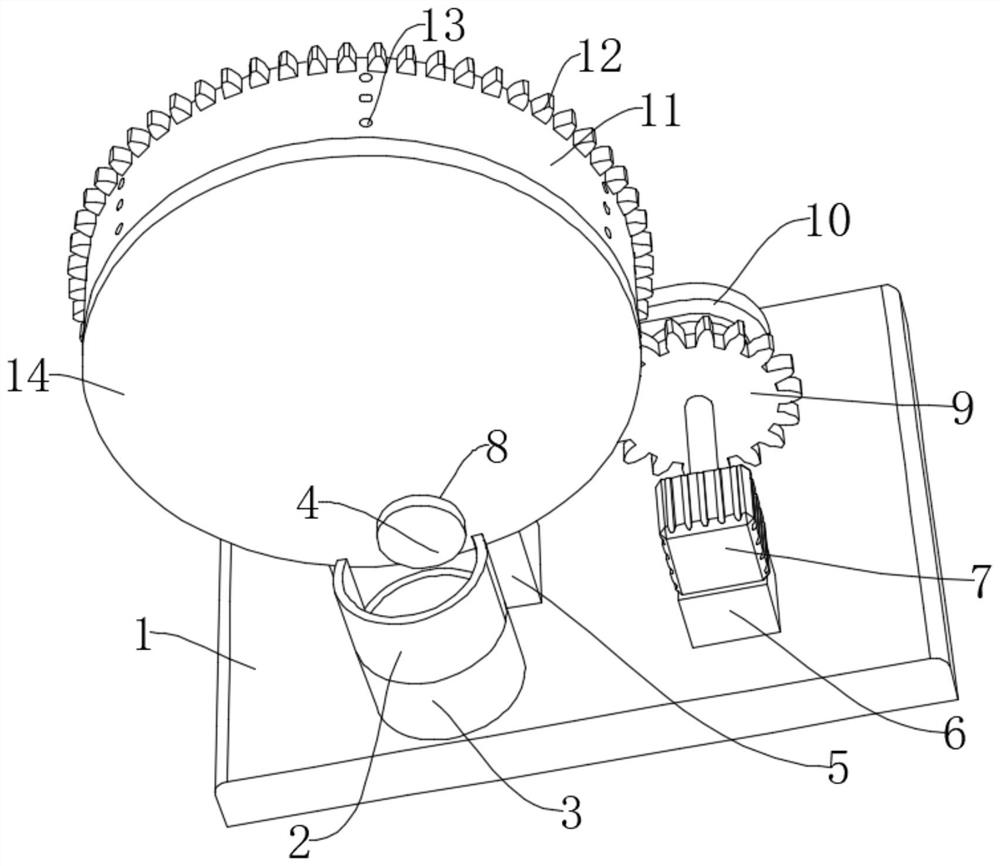

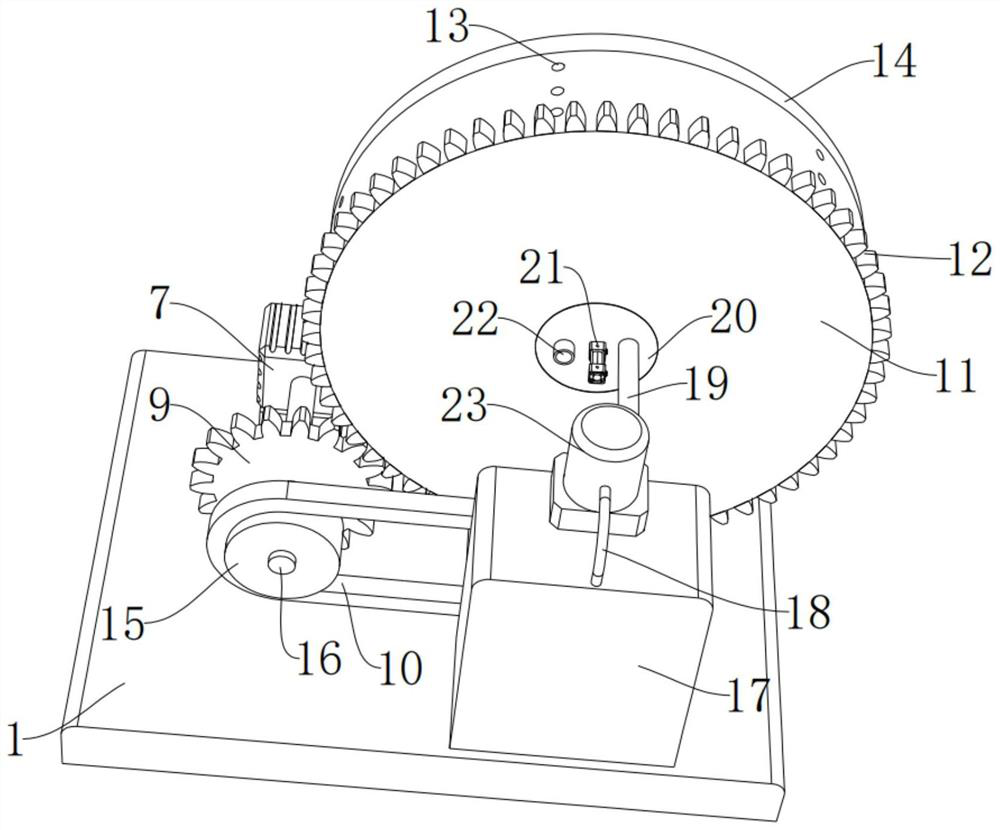

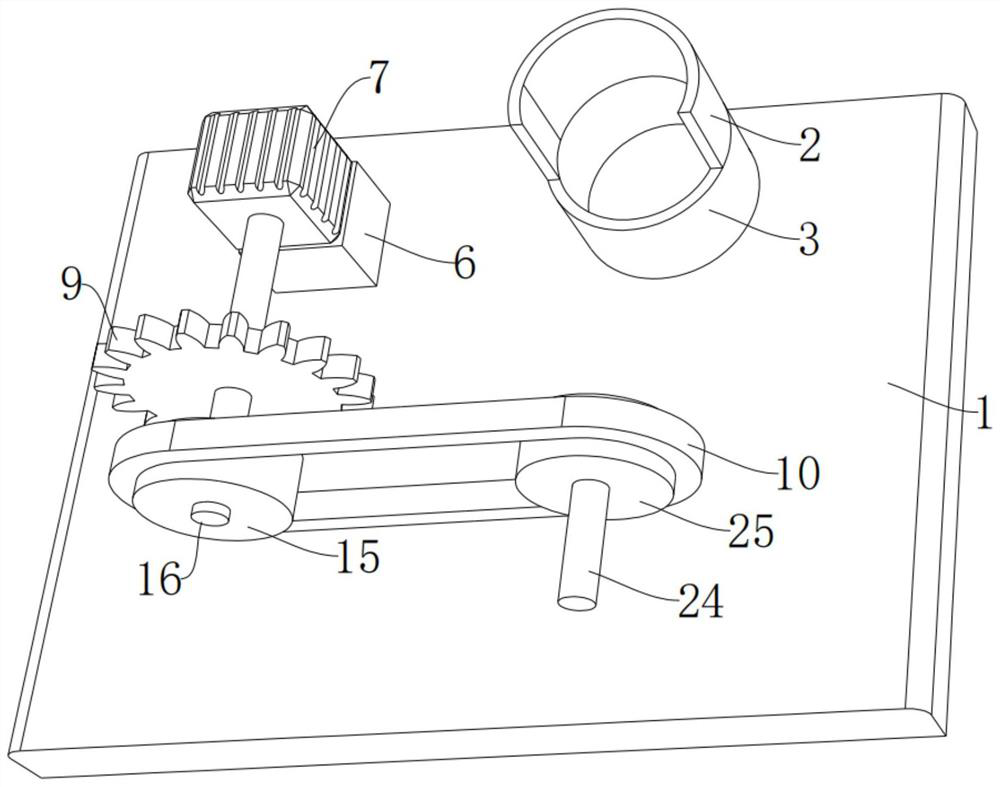

[0031] refer to Figure 1-8 , a coating machine capable of intelligent temperature control, comprising a bottom plate 1, a support frame 5 is fixedly connected to the top of the bottom plate 1, and a coating cylinder 11 is rotatably connected to the top of the support frame 5, and one side of the coating cylinder 11 is fixed by bolts The cover plate 14 used in conjunction is connected, and one side of the coating cylinder 11 rotates through an outer cylinder 29. The outer wall of the outer cylinder 29 is annularly distributed with a plurality of first air outlet holes 31, and the outer cylinder 29 is located on the outside of the coating cylinder 11. One end is fixedly connected with a side plate 20, and the inside of the side plate 20 is fixedly penetrated by a hot air pipe 22, and one end of the hot air pipe 22 located outside the outer cylinder 29 is connected with an external heating device, and one side of the side plate 20 is fixedly connected with a controller 37. The i...

Embodiment 2

[0033] refer to Figure 1-8, a coating machine capable of intelligent temperature control, comprising a bottom plate 1, a support frame 5 is fixedly connected to the top of the bottom plate 1, and a coating cylinder 11 is rotatably connected to the top of the support frame 5, and one side of the coating cylinder 11 is fixed by bolts The cover plate 14 used in conjunction is connected, and one side of the coating cylinder 11 rotates through an outer cylinder 29. The outer wall of the outer cylinder 29 is annularly distributed with a plurality of first air outlet holes 31, and the outer cylinder 29 is located on the outside of the coating cylinder 11. One end is fixedly connected with a side plate 20, and the inside of the side plate 20 is fixedly penetrated by a hot air pipe 22, and one end of the hot air pipe 22 located outside the outer cylinder 29 is connected with an external heating device, and one side of the side plate 20 is fixedly connected with a controller 37. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com