Full-automatic groove broacher for variable damping gas spring cylinder barrel

A gas spring and variable damping technology, which is applied in the field of mechanical parts manufacturing, can solve the problems of increasing manufacturing costs, time-consuming and labor-intensive, and low efficiency, and achieve the effects of ensuring production efficiency, saving repeated steps, and realizing fully automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

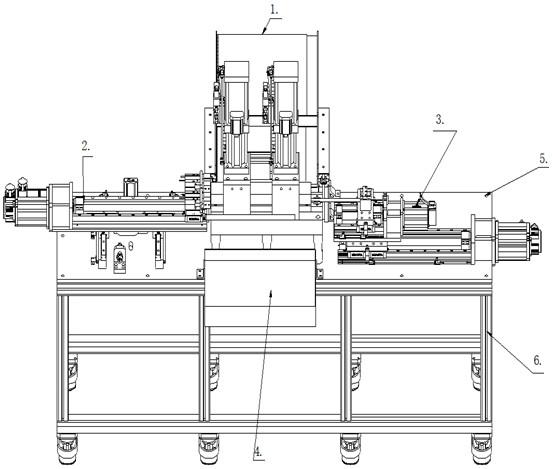

[0026] Such as figure 1 As shown, a fully automatic grooving machine for a variable damping gas spring cylinder, including a work surface 5, a support stand 6, and a loading mechanism 1 fixed on the work surface, a loading and unloading transmission mechanism 2, and a grooving action mechanism 3 and lower material box 4.

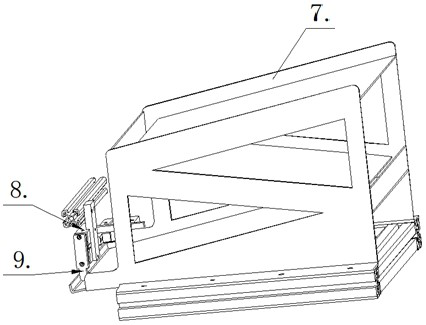

[0027] Such as figure 2 As shown, the feeding mechanism 1 includes a feeding box 7 and a cylinder one 8, the cylinder one is connected with a push rod 9, and the cylinder barrel is pushed onto the worktable by the push rod.

[0028] In this embodiment, the feeding box has a three-layer structure, which has a large capacity and takes up little space; the steel pipes are discharged in a single layer, which leads to better guidance and is not easy to jam.

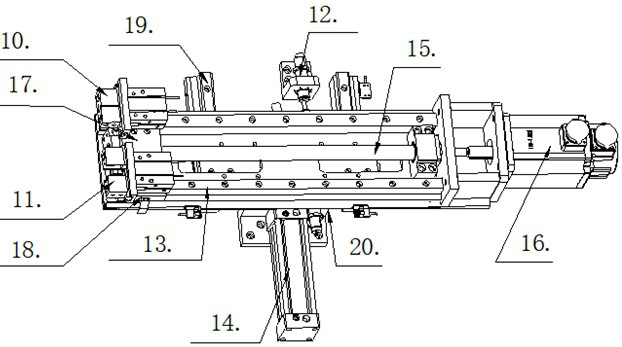

[0029] Such as image 3 As shown, the loading and unloading transmission mechanism includes a base plate 17, a guide rail 13 is provided on the base plate 1, a slide table 18 is provided on the guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com