Station transfer device for welding motorcycle frame

A frame welding and transmission device technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large space occupation, long process, and prone to deviations, etc., to reduce occupied space, fast cycle, ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

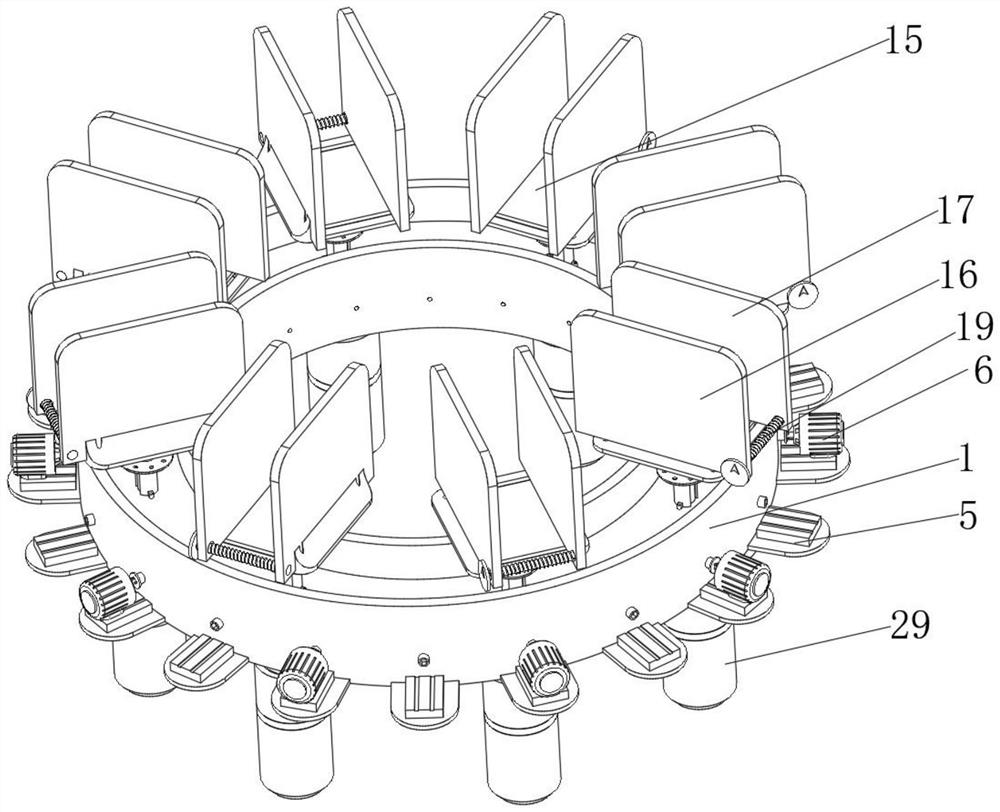

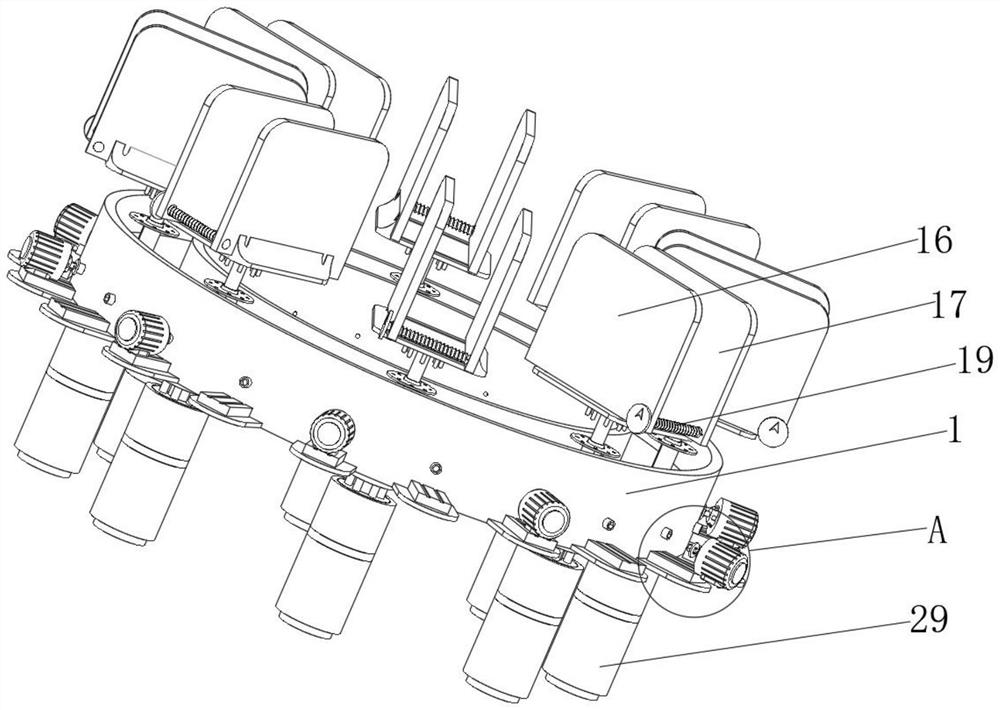

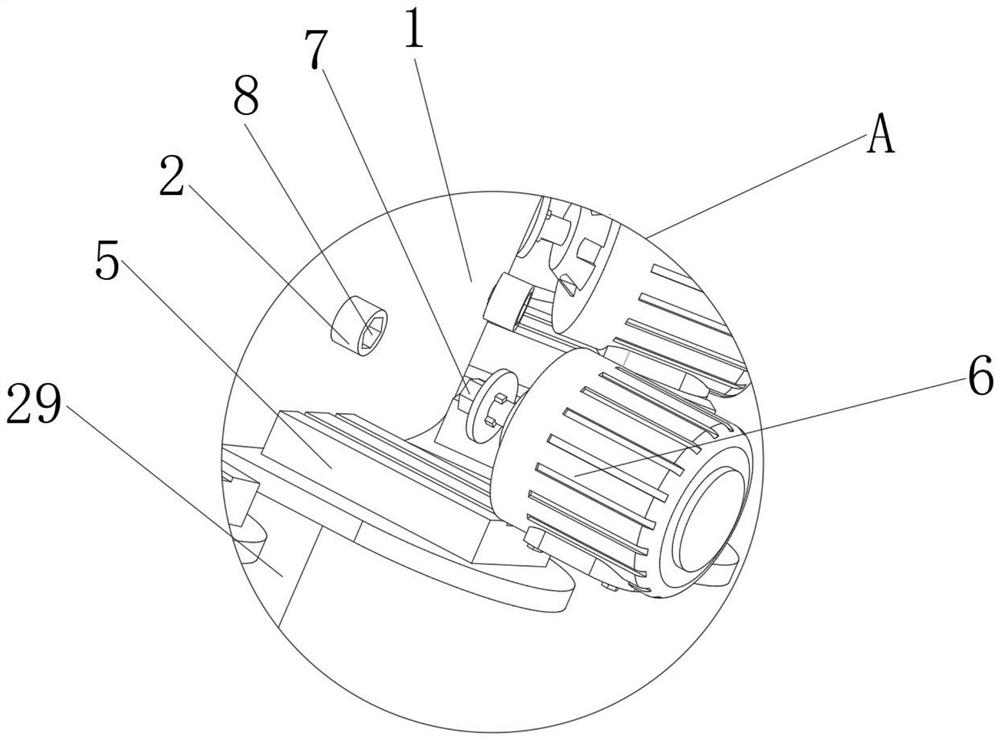

[0031] see figure 1 with 4 , the present invention provides a technical solution: a motorcycle frame welding station transmission device, including a ring frame 1, the inner side of the ring frame 1 is rotatably connected with a central shaft 2, and the outer surface of the central shaft 2 is equipped with a roller 3, which passes through the central shaft The rotation of 2 can rotate the electric drum 3, the upper surface of the drum 3 is provided with a slideway 4, the lower surface of the slideway 4 is equipped with a rubber pad, and the outer surface of the drum 3 is provided with a booster groove, through the cooperation of the booster groove and the rubber pad The propulsion function of the drum 3 when rotating can be improved, and the slideway 4 fits the drum 3. The purpose of this design is to realize the driving effect of the drum 3 on the slideway 4. The slideway 4 is rotatably connected to the ring frame 1. Inside, the shape of the slideway 4 is ring-shaped. The pu...

Embodiment 2

[0034] see Figure 5-6, the upper surface of the slideway 4 is provided with a bracket 9, the outer surface of the bracket 9 is equipped with a mounting plate, the upper surface of the mounting plate is provided with a mounting hole, and the fixing of the bracket 9 can be realized by driving a screw into the position of the mounting hole The installation function, and then the support 9 is freely placed on the required position on the slideway 4, and the flexibility in the operation process of the station transmission device is improved. A bearing is connected in rotation, and the upper surface of the bearing is connected with a support plate 11 in rotation. The purpose of this design is to provide preconditions for the rotation of the support plate 11. The outer surface of the top of the bracket 9 is equipped with an annular plate 13, and the ring plate 13 Limiting holes 14 are provided on the upper surface, and limit rods 12 are installed on the lower surface of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com