A kind of finishing process of stator and rotor for automobile engine

A technology of automobile engines and stators and rotors, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools. It can solve the problems of inconvenient and quick replacement, affecting the processing efficiency of engine stators and rotors, and affecting the normal operation of the transmission structure on the machine tool, so as to ensure the finishing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

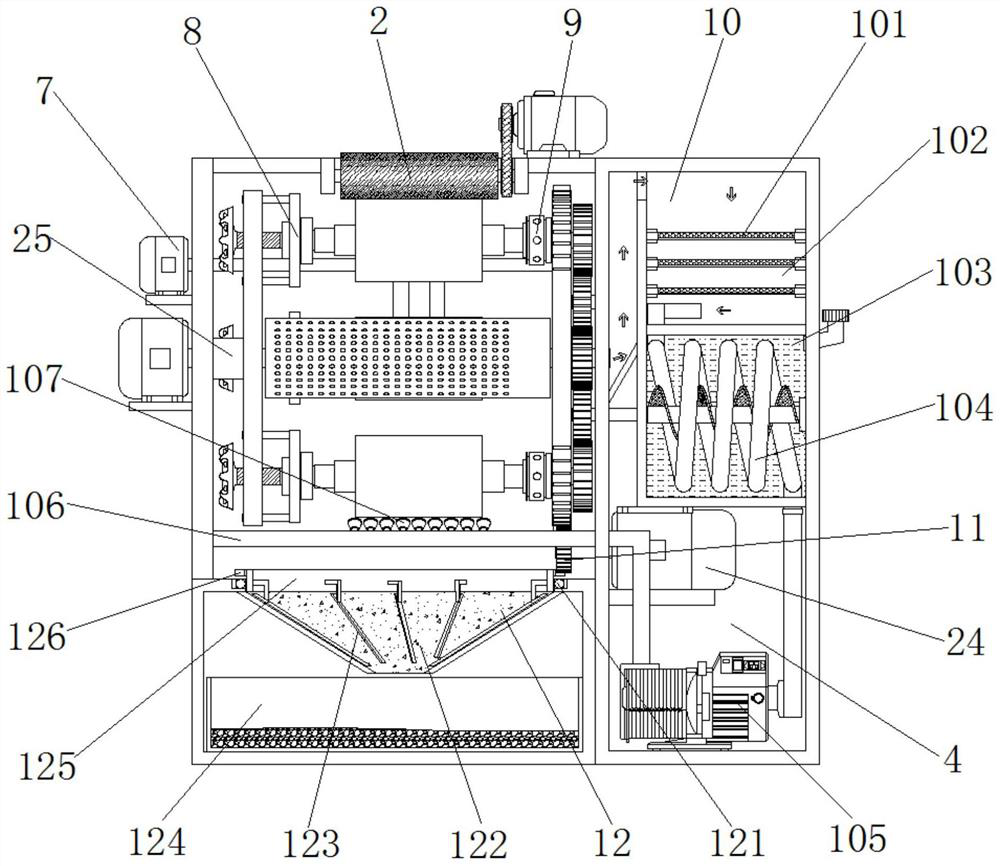

[0053] Example 1, as Figure 2-4 As shown in the figure, before finishing the stator and rotor, the operator passes his hand through the square through hole and then rotates a set of handwheels 803 close to the door of the processing chamber 1 counterclockwise, and uses the thread action to force the threaded rod 805 to move closer to the first servo motor. One end of 6 moves, driving the rotating plate 801 to approach the first servo motor 6 together, and the distance between the rotating plate 801 and the rotating holder 9 increases, and then the operator manually inserts one end of the stator and rotor into the recess of the rotating holder 9. slot, and turn the hand wheel 803 clockwise, so that the other end of the stator and rotor is clamped into the slot 806, so as to install the stator and rotor, so as to facilitate the subsequent finishing of the stator and rotor, and replace the finished stator and rotor. At this time, turn the handwheel 803 clockwise to drive the thr...

Embodiment 2

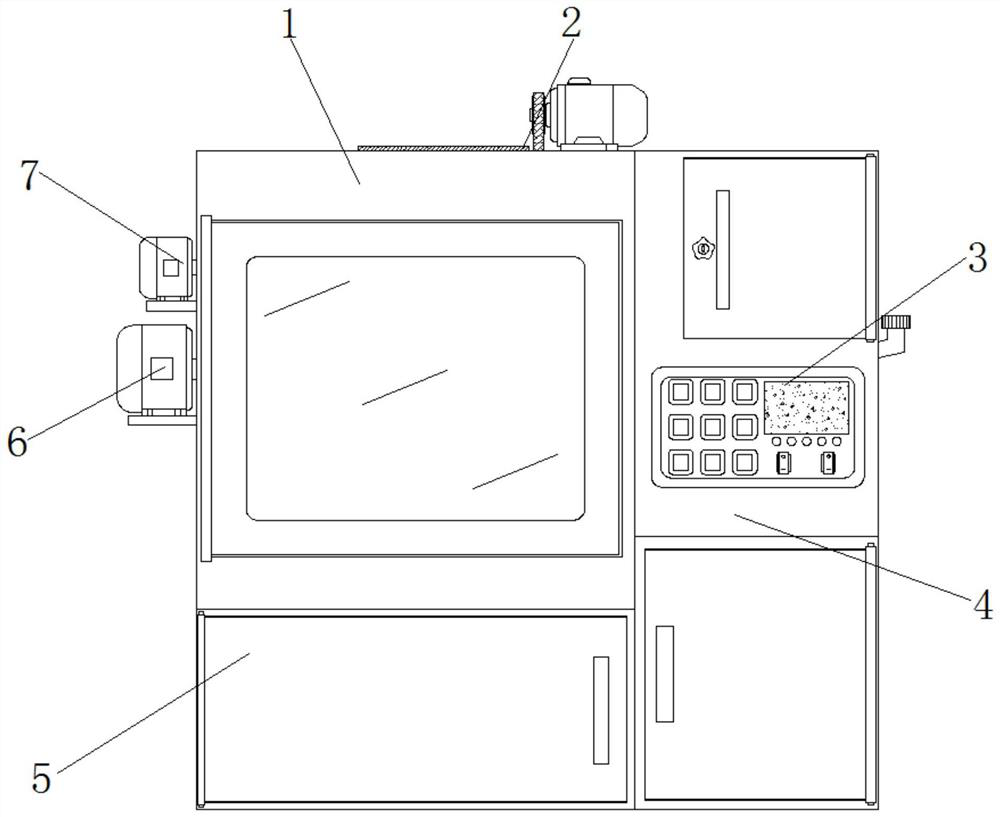

[0054] Example 2, as Figure 1-10 As shown in the figure, when finishing the stator and rotor, the device first controls the second servo motor 24 to rotate clockwise through the control panel 3, and uses the transmission of the driving gear 11 and the second ring rack 19 to drive the two sets of turntables 13 to reverse each time. The clockwise is rotated 90°, so that the stator and rotor pass through the bottom of the grinding device 2 in turn, and then pass through one side of the turning assembly 7 and the top of the rotating ring 125, and when the turntable 13 stops, the first servo motor 6 drives the rotating chamber. 14 rotates, and the rotating bin 14 drives the three sets of rotating chucks 9 to rotate synchronously through the driving gear 18 on the first rotating tube 17 and the three sets of transmission gears 23, thereby driving the three sets of stators and rotors to rotate synchronously. The grinding device 2 is used to align the stator and rotor Grinding is per...

Embodiment 3

[0055] Example 3, as Figure 2-6 As shown in and 9-10, when dusting the inside of the processing bin 1, the air suction pump 105 is controlled by the control panel 3 to inhale, and the metal dust generated by the grinding device 2 is mixed with the air and enters the rotating bin 14 through the air inlet 15. After that, the metal dust and air enter the interior of the filter chamber 102 through the first rotating pipe 17, and the metal dust will be filtered and blocked by the three sets of filter screens 101, and the filtered air will pass through the heat exchange pipe 104. The air pump 105 is transported to the inside of the air pipe 106, and the filtered air is finally sprayed out through the nozzle 107 to blow and cool the surface of the bottom group of stators and rotors, so that the processed stators and rotors can be quickly replaced, and the nozzles 107 spray out The surface of the set of stators and rotors will also be blown and dusted, and the blown dust will also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com