Assembly control method, device and system and storage medium

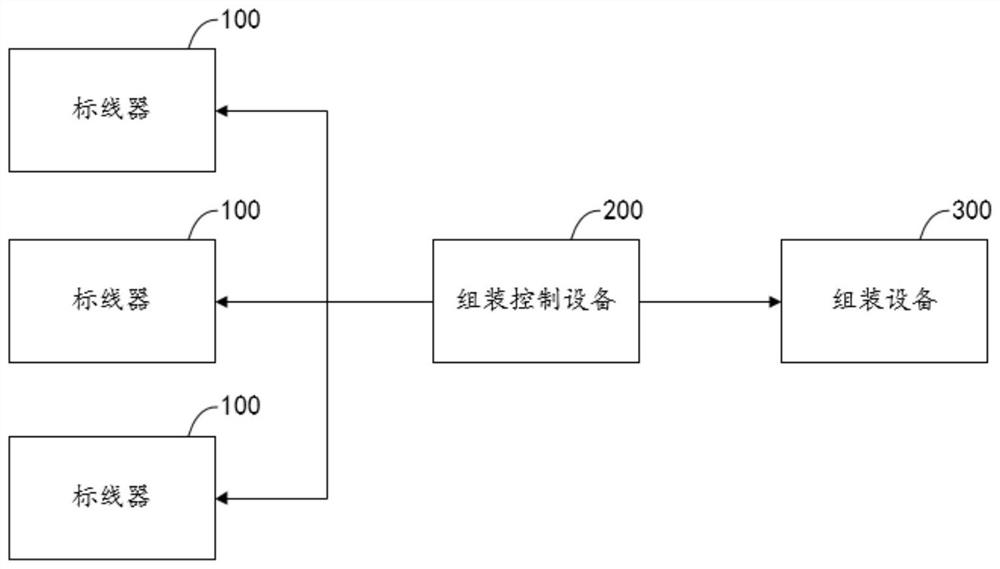

A control system and control method technology, applied in the field of truck parts assembly, can solve the problem of low assembly accuracy of assemblies or assemblies, achieve the effect of meeting the running speed and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

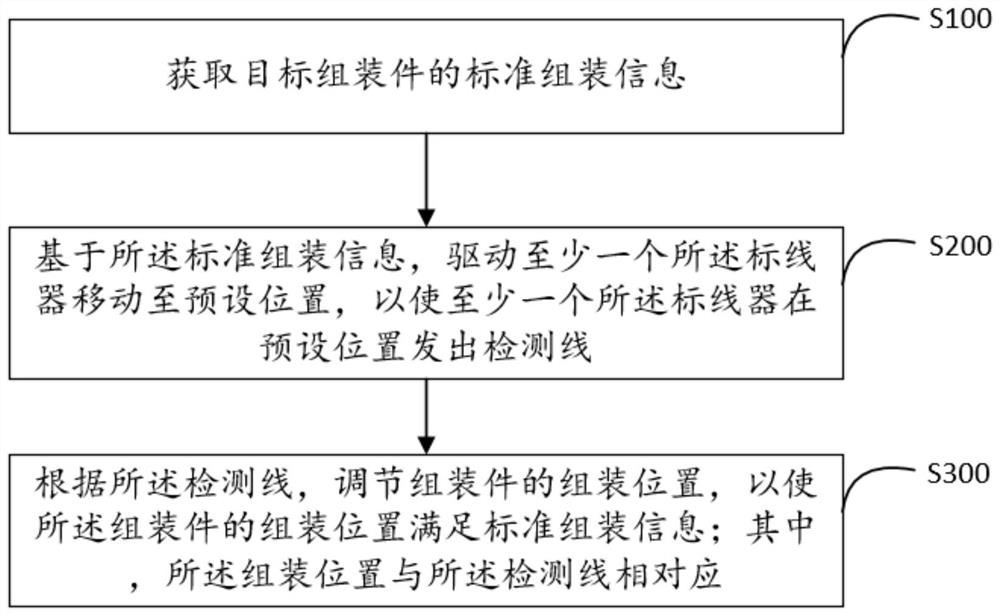

[0091] For ease of understanding, see Figure 4 , Figure 4 It is a schematic flowchart of the second embodiment of the assembly control method of the present invention. based on image 3 As shown in the first embodiment of the assembly control method, this embodiment provides a second embodiment of the assembly control method. In this embodiment, the assembly control system also includes assembly equipment. Therefore, in step S300, according to the The detection line is used to adjust the assembly position of the assembly so that the assembly position of the assembly meets the standard assembly information, which may specifically include the following:

[0092] Step S301 , generating a position adjustment command of the assembly according to the detection line.

[0093] In this embodiment, after the detection line used to guide or indicate the assembly position of the target assembly is generated, the target assembly can be assembled according to the detection line, and th...

Embodiment approach

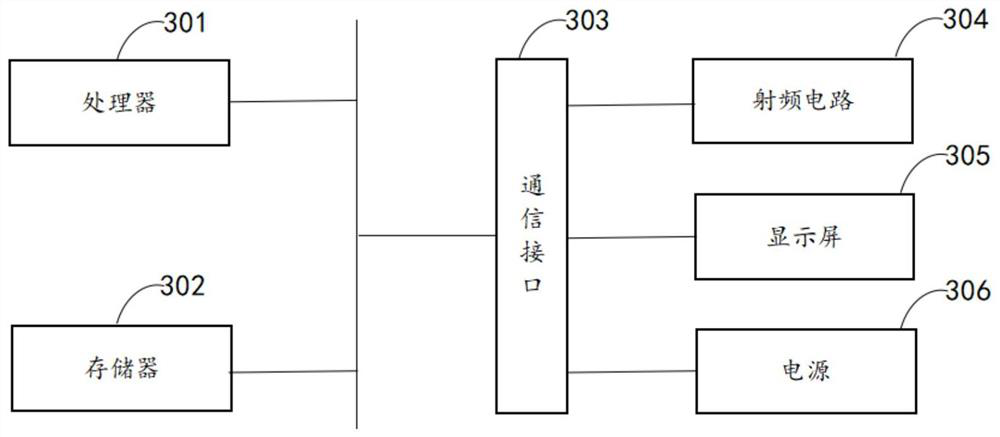

[0105] As an implementation manner, the assembly control device further includes an establishment module 40, which is used to collect standard assembly information of the assembly; wherein, the standard assembly information is the position information of the assembly in a standard assembly state ; Based on the standard assembly information, an assembly information mapping table is established; wherein, the assembly information mapping table stores at least one assembly and its corresponding standard assembly information.

[0106] As an implementation, the acquiring module 10 is also used to acquire the assembly control instruction of the target assembly; wherein, the target assembly includes at least one target assembly, and the assembly control instruction is the corresponding A control instruction: using the assembly control instruction to traverse the assembly information mapping table to obtain at least one standard assembly information corresponding to the target assembly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com