Transmission device of regenerated cellulose film forming machine

A technology of regenerated cellulose and transmission device, which is applied to electromechanical devices, electric components, and mechanical energy control. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

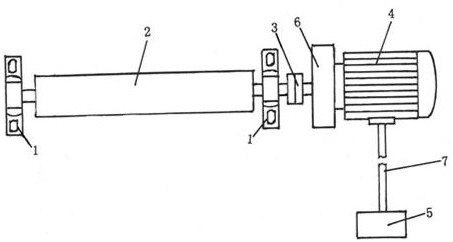

[0008] figure 1 Shown: the transmission device used in the regenerated cellulose film molding machine, the side end of the paper threading roller 2 with the bearing housing 1 at both ends is connected to the motor 4 with the transmission 6 through the coupling 3, and the motor 4 passes through the line 7 A frequency converter 5 is connected.

[0009] The frequency converter 5 involved in this technical solution can be directly configured through the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com