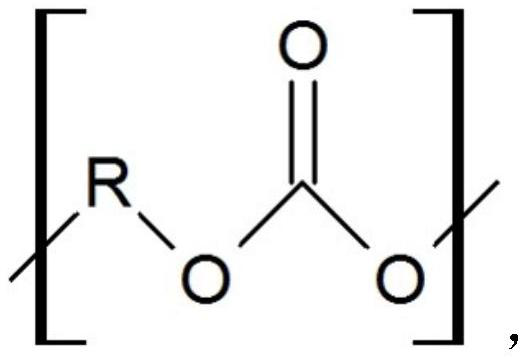

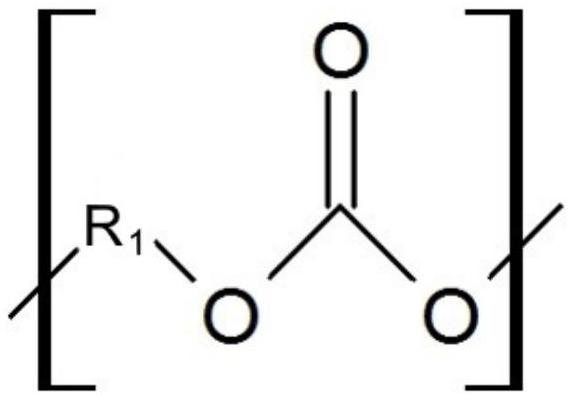

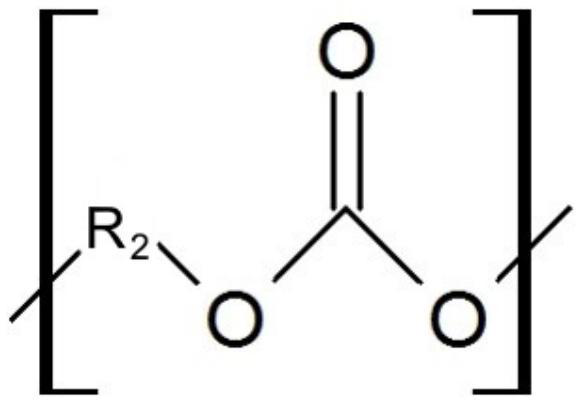

Polycarbonate polyol and application thereof

A technology of polycarbonate and polyol, applied in the field of polycarbonate polyol, can solve the problem that polycarbonate polyol cannot provide elastomer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] 1.3. Preparation of polycarbonate polyols

[0064] 1.3.1. Transesterification of carbonates and polyols

[0065] The polycarbonate polyol of the present invention can be obtained by transesterifying a carbonate ester and a polyol. In some embodiments of the present invention, the polycarbonate polyol is obtained by performing transesterification reaction between carbonate ester and polyol in the presence of a catalyst.

[0066] Examples of catalysts that can be used to prepare polycarbonate polyols include, but are not limited to, metals, metal salts, metal alkoxides, metal oxides, metal hydrides, metal hydroxides, metal carbonates, metal amides, and metal boron salt. Examples of the foregoing metals include, but are not limited to, lithium, sodium, potassium, magnesium, calcium, strontium, barium, aluminum, titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, gallium, germanium, zirconium, niobium, Molybdenum, ruthenium, rhodium, palladium, s...

Synthetic example 1

[0096] In a glass round-bottomed flask equipped with a rectifying tube, a stirrer, a thermostat and a nitrogen inlet tube, add the following raw materials: 1004 grams of dimethyl carbonate, 556 grams of 1,4-butanediol, 251 grams of 2- Butyl-2-ethyl-1,3-propanediol, 58 grams of 3-methyl-1,5-pentanediol, and 0.1 grams of tetrabutoxytitanium (catalyst). Next, stirring was carried out under normal pressure and nitrogen flow conditions, and transesterification reaction was performed for 8 hours while distilling off the mixture of methanol and dimethyl carbonate. During the transesterification reaction, the reaction temperature was slowly raised from 95°C to 150°C, and the composition of the distillate was adjusted to an azeotropic composition of methanol and dimethyl carbonate. Thereafter, the pressure was gradually reduced to 100 Torr, and a transesterification reaction was further performed for 1 hour while distilling off a mixture of methanol and dimethyl carbonate under conditi...

Synthetic example 2

[0098] Prepare the polycarbonate diol of Synthesis Example 2 in the same manner as Synthesis Example 1, but add the following raw materials instead: 829 grams of dimethyl carbonate, 312 grams of 1,4-butanediol, 477 grams of 2-butane 2-ethyl-1,3-propanediol, 57 grams of 3-methyl-1,5-pentanediol, and 0.24 grams of tetrabutoxytitanium (catalyst). The weight of the polycarbonate diol in Synthesis Example 2 was 1032 g, and the hydroxyl value was 54.77 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com