Reinforced seepage and drainage water collecting pipe and using method thereof

A technology for seepage and drainage and collection pipes, applied in the field of seepage and drainage pipes, can solve the problems of easily damaged waterproof layer, low load-bearing capacity of U-shaped structure, damage to filter cloth, etc., and achieves the effect of increasing the contact area and facilitating integrated injection molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

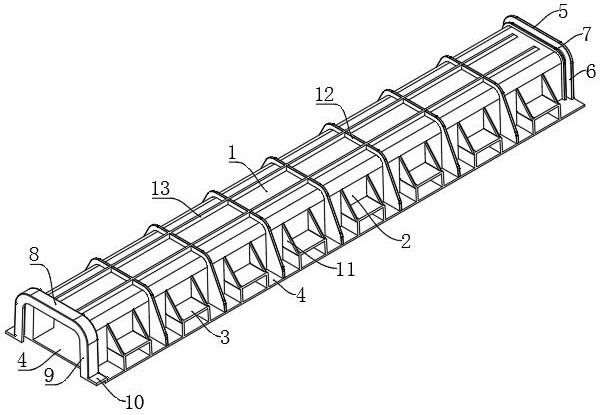

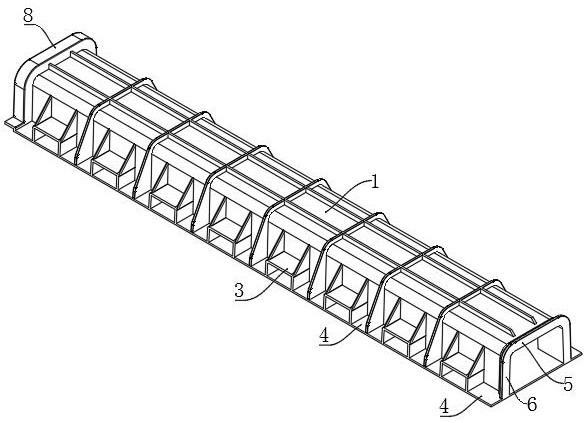

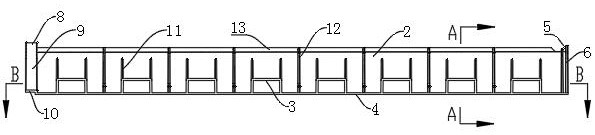

[0035] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0036] like Figure 1~9 As shown, a reinforced seepage drainage collection pipe of the present invention is integrally injection-molded, including a horizontally arranged pipe body, the pipe body includes a top plate 1, a bottom plate 4 and vertical plates 2 extending downward from both sides of the top plate 1, The lower end of the vertical plate 2 is affixed to the upper surface of the bottom plate 4 , so that the top plate 1 , the bottom plate 4 and the vertical plate 2 form a pipe body with a rectangular cross-section.

[0037] The bottom plate 4 extends horizontally to the outside of the vertical plate 2 , thereby increasing the area of the bottom plate 4 .

[0038] The vertical board 2 is connected with a plurality of water inlet pipes 3 extending to the outside of the pipe body, the water inlet pipes 3 on the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com