Controller for realizing full-rotation composite orientation of drill string

A full-rotation, controller technology, applied in directional drilling, drill pipe, drill pipe, etc., can solve the problems of low drilling efficiency and drilling speed, difficult to control well trajectory, high cost of rotary drilling, etc., to reduce the risk of stuck pipe , Conducive to wellbore cleaning and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

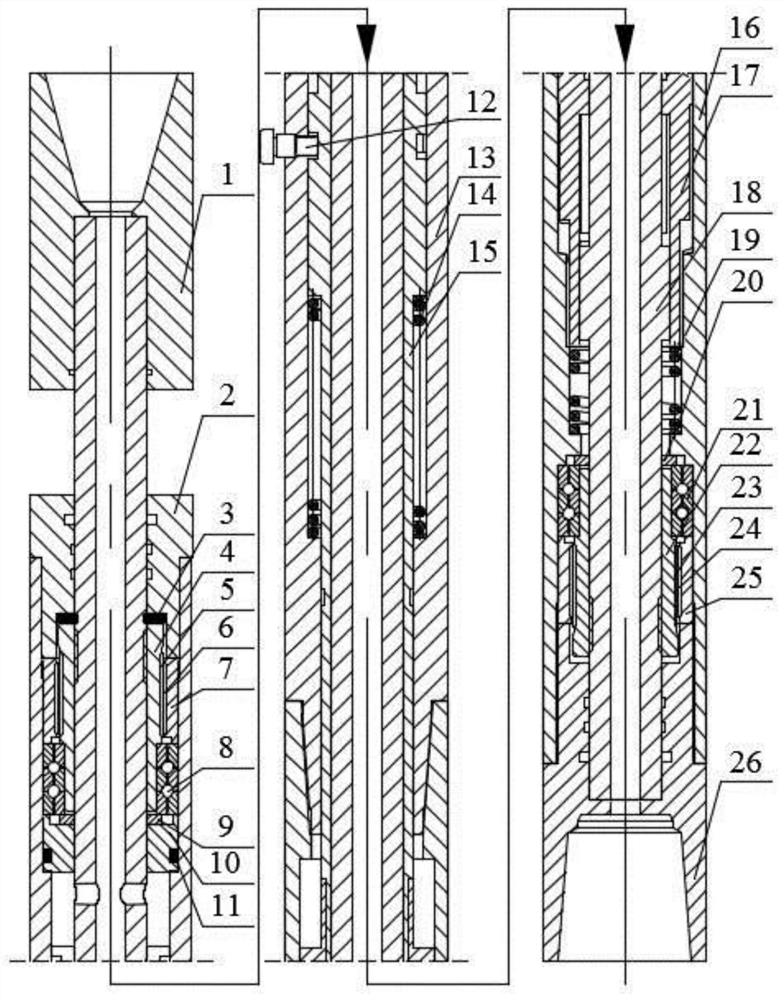

[0021] See attached figure 1 , the present invention relates to a controller that is installed with a clutch conversion cylinder 15 and a spline sleeve 17 to realize the full rotation compound orientation of the drill string. The directional controller controls the "off" state and "on" state.

[0022] The controller for realizing the compound orientation of the full rotation of the drill string has a clutch housing 13 and a spline housing 16, a clutch conversion cylinder 15 and a return spring A14 are arranged in the clutch housing 13, and a spline sleeve 17 and a return spring are arranged in the spline housing 16 B19, the clutch housing 13 and the spline housing 16 enclose the mandrel 18 together. The outer wall of the upper end of the clutch conversion cylinder 15 is provided with a circumferential chute, the chute is provided with a control screw 12, and the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com