Silencing device

A technology of muffler device and muffler chamber, applied in muffler device, exhaust device, engine components, etc., can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

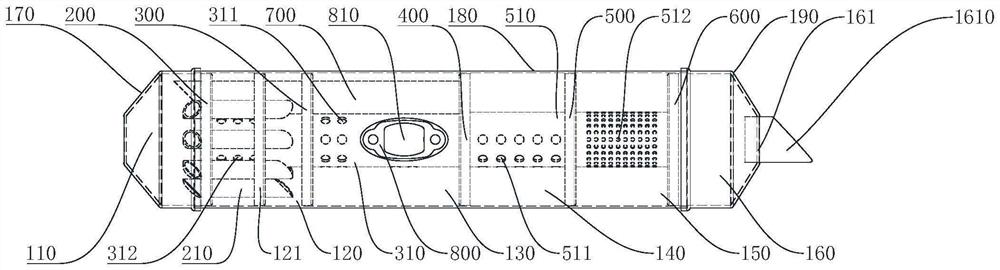

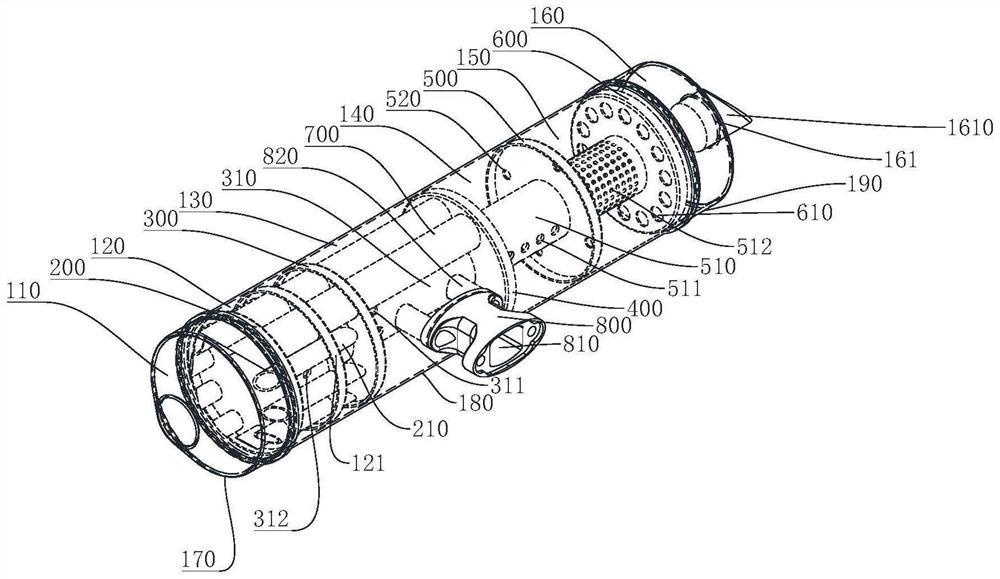

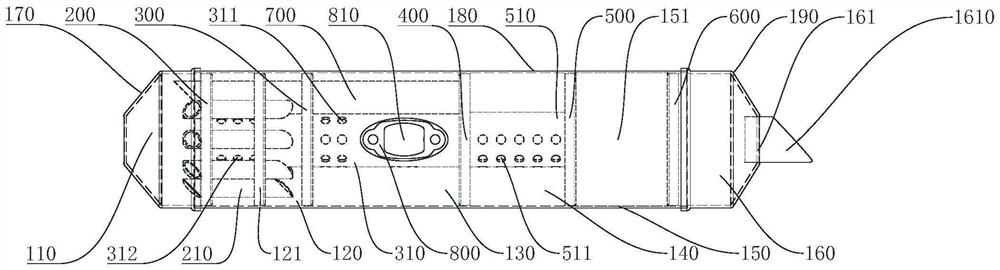

[0042] see Figure 1 to Figure 2 and Figure 5 to Figure 7 . What this embodiment describes is a noise reduction device, which includes an outer shell, and a first partition 200, a second partition 300, a third partition 400, a fourth The baffle 500 and the fifth baffle 600 divide the outer shell into the first anechoic chamber 110, the second anechoic chamber 120, the third anechoic chamber 130, the fourth anechoic chamber 140, the fifth anechoic chamber 150 and the sixth anechoic chamber 160, An air inlet 131 is provided on the outer shell of the third anechoic chamber 130 , and a first ventilation pipe 310 is provided on the second partition 300 , and one end of the first ventilation pipe 310 is installed on the first partition 200 , the other end of the first air pipe 310 is installed on the third partition 400, and the first air pipe 310 located in the third anechoic chamber 130 is provided with a plurality of first air inlet holes 311, located in the second anechoic ch...

Embodiment 2

[0053] see Figure 3 to Figure 7 . What this embodiment describes is a noise reduction device, which includes an outer shell, and a first partition 200, a second partition 300, a third partition 400, a fourth The clapboard 500 and the fifth clapboard 600 divide the outer shell into the first anechoic chamber, the second anechoic chamber, the third anechoic chamber 130, the fourth anechoic chamber 140, the fifth anechoic chamber 150 and the sixth anechoic chamber 160, located in the The outer casing of the third anechoic chamber 130 is provided with an air inlet 131, and the second partition 300 is provided with a first ventilation pipe 310, and one end of the first ventilation pipe 310 is installed on the first partition 200, and the second The other end of a ventilation pipe 310 is installed on the third partition 400, and the first ventilation pipe 310 located in the third anechoic chamber 130 is provided with a plurality of first air inlets 311, and the first aeration hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com