Noise-suppression edge grinding wheel

An edging wheel and sound-absorbing technology, which is applied in the direction of abrasive materials, bonded grinding wheels, and metal processing equipment, can solve the problem of unsatisfactory noise reduction effect of diamond edging wheels, and achieve good processing quality, low working noise and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

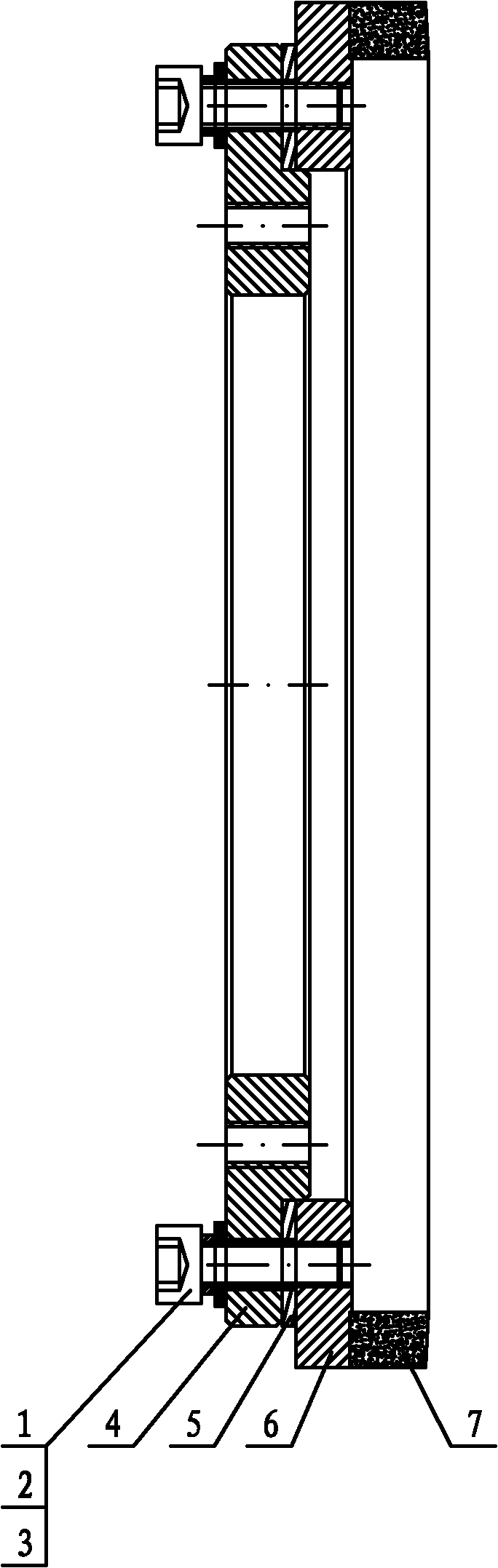

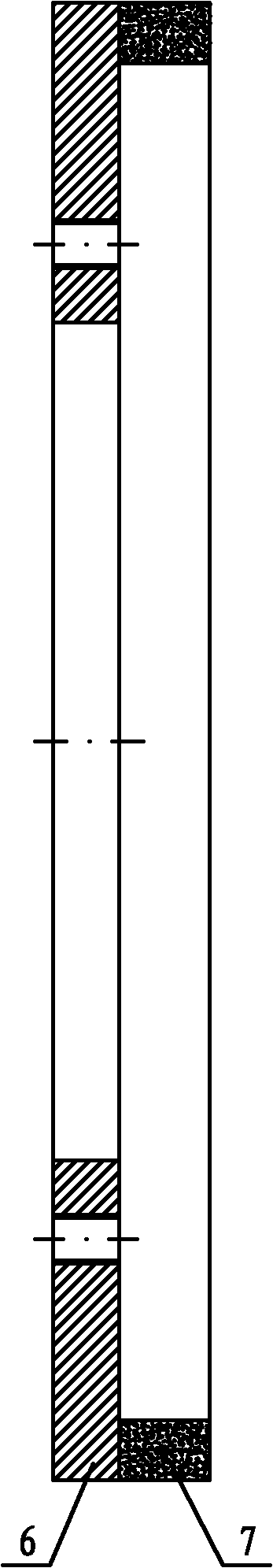

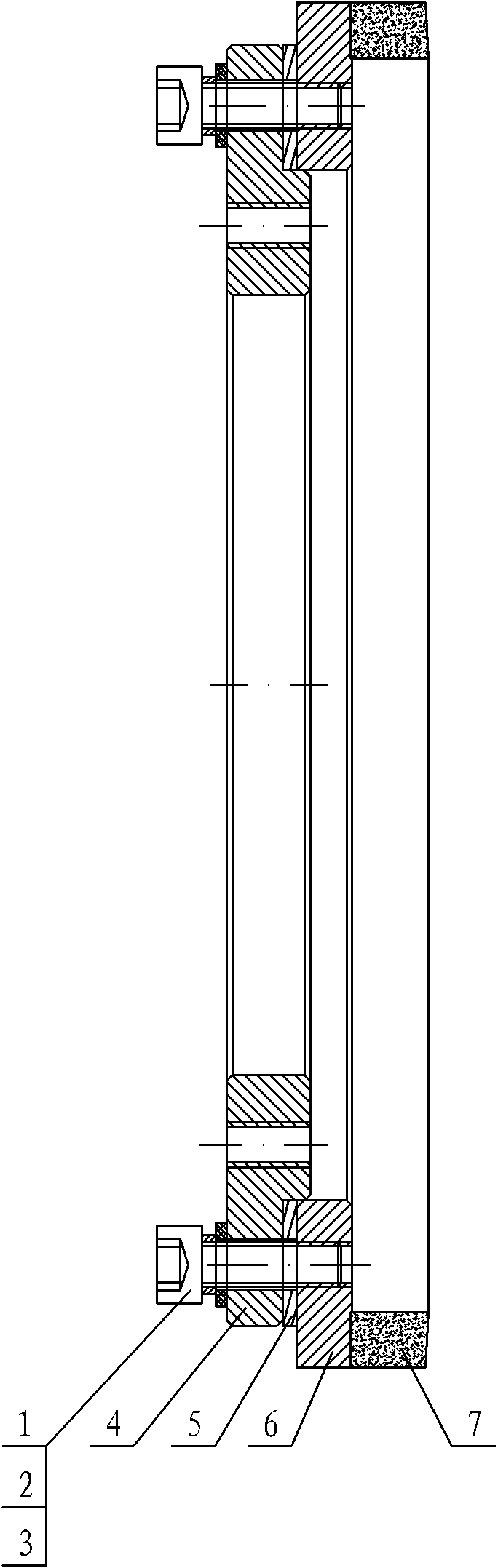

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] see Figure 1-Figure 2 , the sound-absorbing edging wheel, including the flange 4 connected with the diamond cutter head base 6, the diamond cutter head 7 is arranged on the diamond cutter head base 6, and there is also a gap between the diamond cutter head base 6 and the flange 4 Silencer ring 5.

[0016] The sound-absorbing ring 5 is a nylon sound-absorbing ring, an aluminum sound-absorbing ring or a copper sound-absorbing ring. When in use, the thickness of the sound-absorbing ring 5 is 0.1-8mm.

[0017] The sound-absorbing ring 5 is connected with the diamond bit base 6 by screws.

[0018] The diamond segments 7 are arranged on the diamond segment base 6 in a ring shape; or, the diamond segments 7 are arranged on the diamond segment base 6 in a ring shape at intervals, and chip discharge ports are arranged between adjacent diamond segments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com