One-way valve and manufacturing method thereof

A technology of one-way valve and valve plate, which is applied in the direction of the control valve, the oil tank of the power unit, the parts in contact between the valve element and the valve seat, etc., and can solve the problems of inability to bond, poor adhesion between rubber and composite materials, and rough surfaces Accuracy can not reach the problem, so as to ensure the sealing performance, solve the effect of unreliable bonding and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the application will be further described:

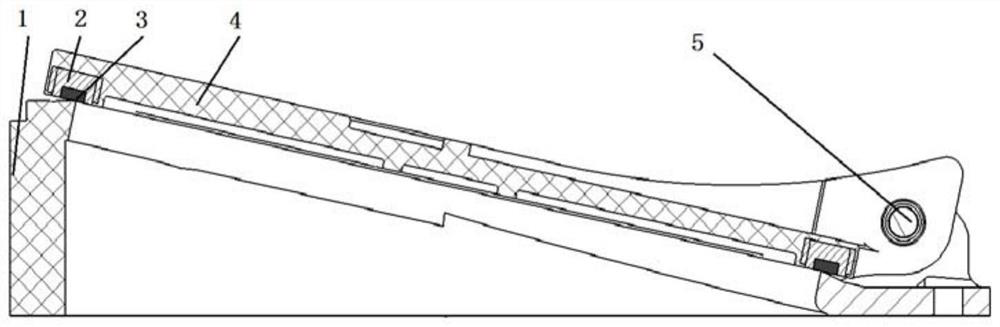

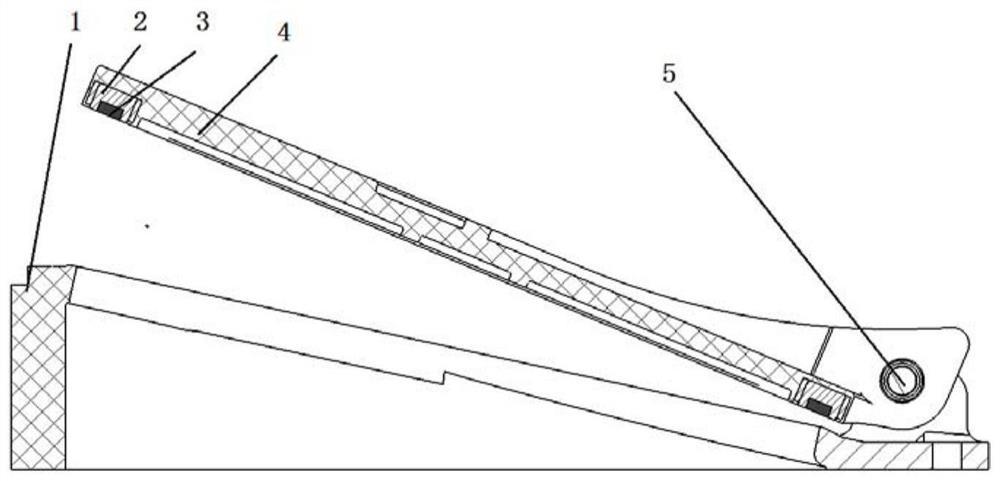

[0030] Such as figure 1 As shown, the present application provides a one-way valve, including: a composite material valve seat 1, a composite material valve plate 4 and a rotating shaft 5, and the composite material valve seat 1 and the composite material valve plate 4 are movably connected through the rotating shaft 5;

[0031] The edge area of the composite valve plate is provided with an annular metal part 2, and a rubber annular groove is formed on the metal part 2, and an adhesive is coated in the rubber annular groove, and the rubber annular groove coated with the adhesive is vulcanized with rubber 3, and the metal The parts are glued to the rubber with an adhesive.

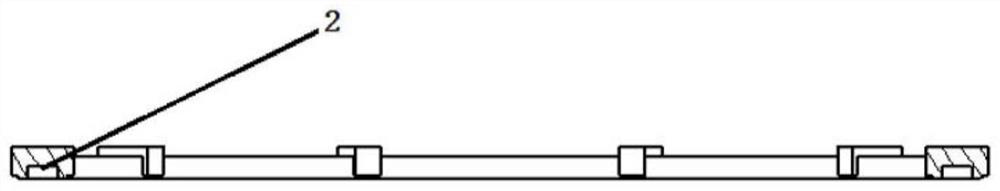

[0032] Such as image 3 As shown, the circumference of the metal part 2 is formed with 10 evenly distributed boss structures, and the material of the boss structures is the same as that of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com