Rapid repairing method for heat supply pipeline

A heating pipeline, fast technology, applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of pipe lines being cut off, heating pipes leaking, etc., to achieve stability assurance, improve process steps, Achieve quick fixes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

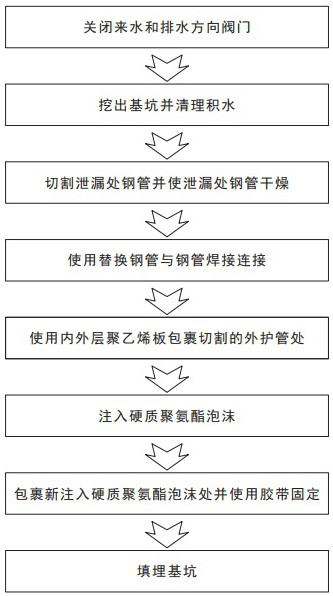

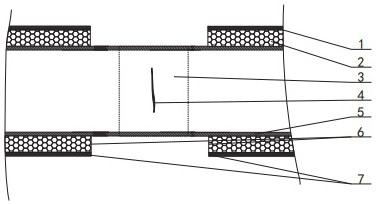

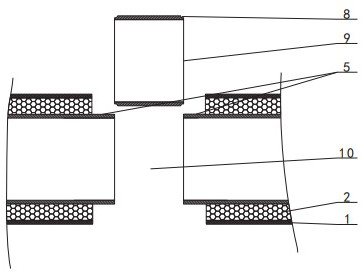

[0046] combined with Figure 1-11 The rapid repair method for heating pipelines described in , the injection method includes the following steps: closing the water inlet and drainage direction valves, digging out the foundation pit and cleaning up the accumulated water, cutting the steel pipe at the leak and drying the steel pipe at the leak, using a replacement The steel pipe is welded to the steel pipe, the inner and outer polyethylene sheets are used to wrap the cut outer protective pipe, inject rigid polyurethane foam, wrap the newly injected rigid polyurethane fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com