Cooling equipment for raw material medicine

A technology of cooling equipment and raw material medicine, which is applied in household refrigeration equipment, lighting and heating equipment, cooling fluid circulation equipment, etc., can solve the problems of poor heat transfer effect, poor dispersion degree, uneven cooling, etc., and achieve cooling effect and effective , control processing cost, long-lasting cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

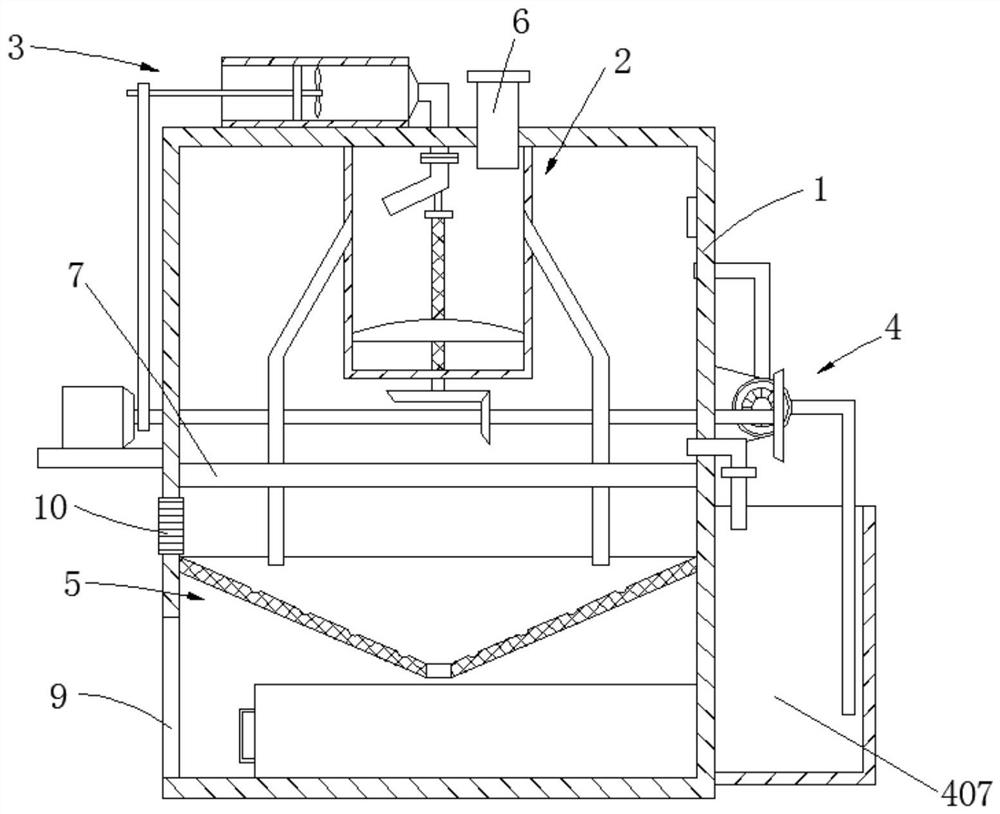

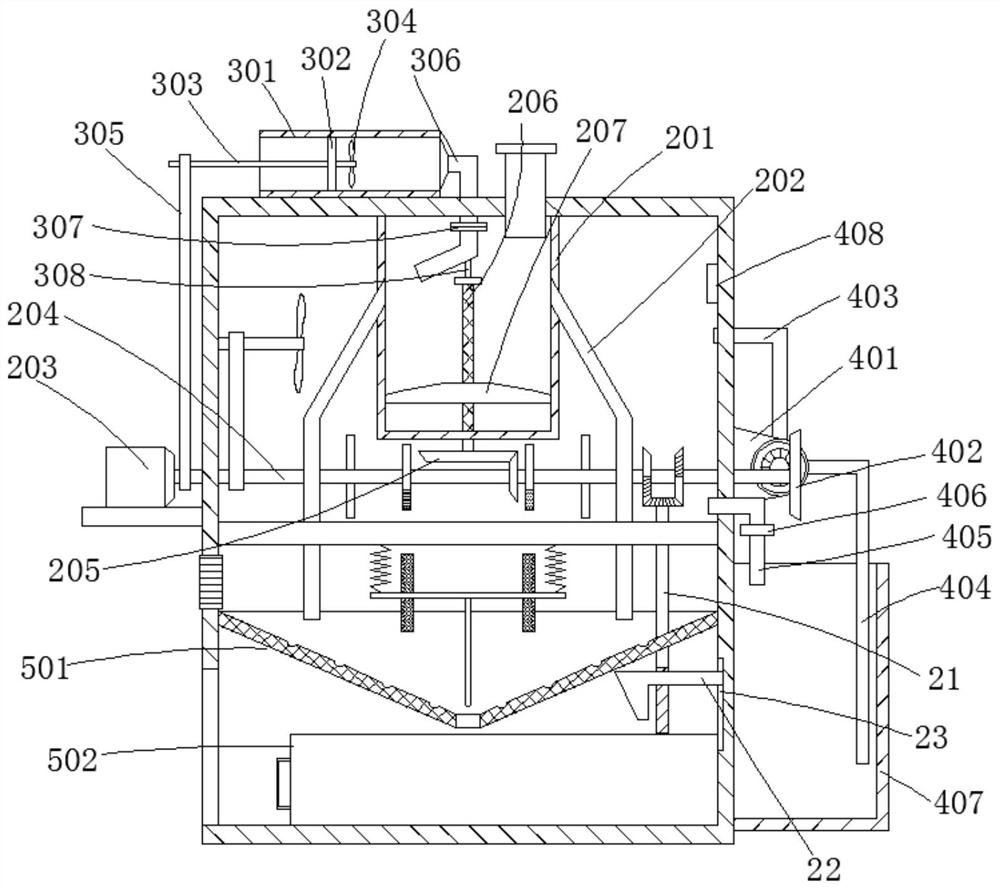

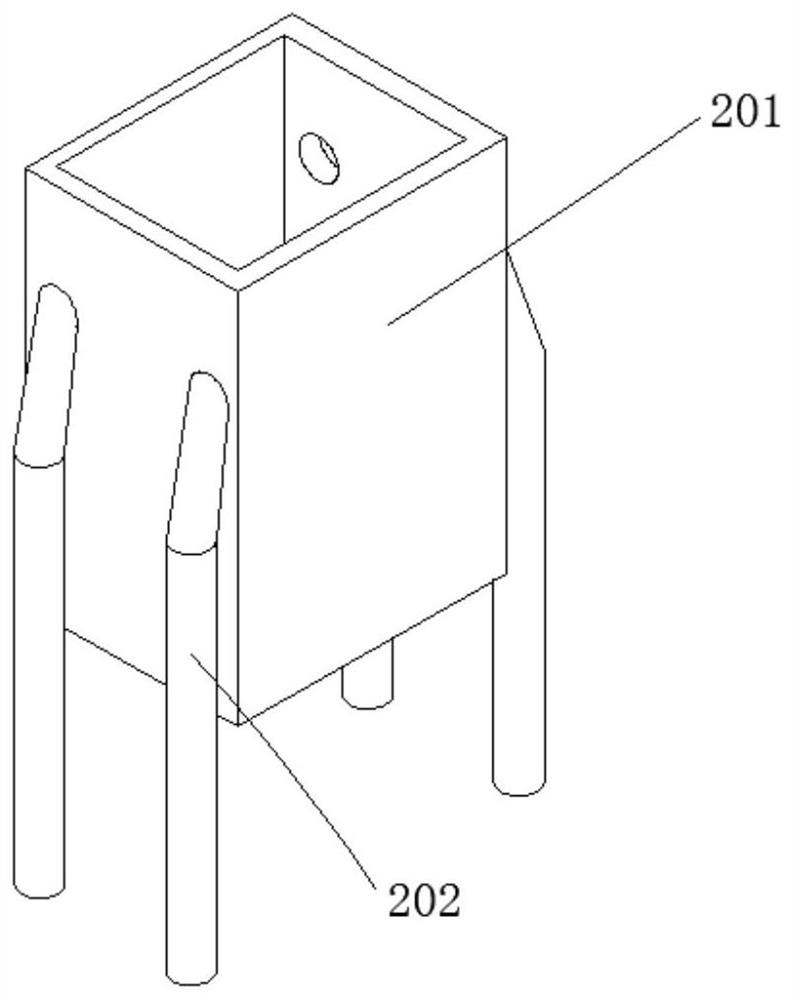

[0042] see Figure 1-7 , the present invention provides a technical solution: a kind of cooling equipment for raw materials, including a main body box 1, a dispersion mechanism 2, an air cooling mechanism 3, a water circulation mechanism 4 and a material collection mechanism 5, and the dispersion mechanism 2 includes a dispersion chamber 201 , material guide pipe 202, motor 203, rotating rod 204, first bevel gear 205, reciprocating screw mandrel 206 and lifting plate 207, dispersion chamber 201 is fixedly connected on the top of main body box 1 inner cavity, and the top of dispersion chamber 201 is connected with Feeding pipe 6, and feeding pipe 6 is provided with capping, the below of dispersion chamber 201 is provided with dividing plate 7, and feed pipe 202 is provided with four, and communicates with the outside of dispersion chamber 201 respectively, and the outside of feed pipe 202 The end passes through the partition 7, the motor 203 is installed on the left side of the...

Embodiment 2

[0047] Compared with embodiment 1, its difference is:

[0048] Wherein, a mixing mechanism is also provided above the dividing plate 7, and the mixing mechanism includes a stirring rod 11, a third rotating rod 12, a second transmission member 13 and a propeller 14, the stirring rod 11 is welded on the rotating rod 204, and the third rotating rod 12 Rotationally connected on the left side wall of the inner cavity of the main body box 1 , the second transmission member 13 is arranged between the rotating rod 204 and the third rotating rod 12 , and the propeller 14 is welded on the end of the third rotating rod 12 .

Embodiment 3

[0050] Compared with embodiment 2, its difference is:

[0051] Wherein, the below of dividing plate 7 is also provided with dredging mechanism, and dredging mechanism comprises rotating disk 15, magnet block 16, spring 17, movable plate 18, magnetic bar 19 and dredging bar 20, and rotating disk 15 is fixedly connected on the rotating rod 204, and magnet block 16 is inlaid on one end of the turntable 15, one end of the spring 17 is fixedly connected to the bottom of the partition 7, the movable plate 18 is horizontally arranged on the other end of the spring 17, the magnetic bar 19 is vertically inserted on the movable plate 18, and is located on the turntable 15 , the dredging rod 20 is fixedly connected to the bottom of the movable plate 18 and is located on the central axis of the collecting hopper 501 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap