Integral vibration clamp for offline vibration test of long-shaft pump

A kind of vibration test, integrated technology, applied in vibration test, machine/structural component test, measuring device, etc., can solve the problems of consuming test equipment man-hours, increasing the stress of the test piece, and being unable to install, etc., so as to achieve easy alignment , save working hours, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

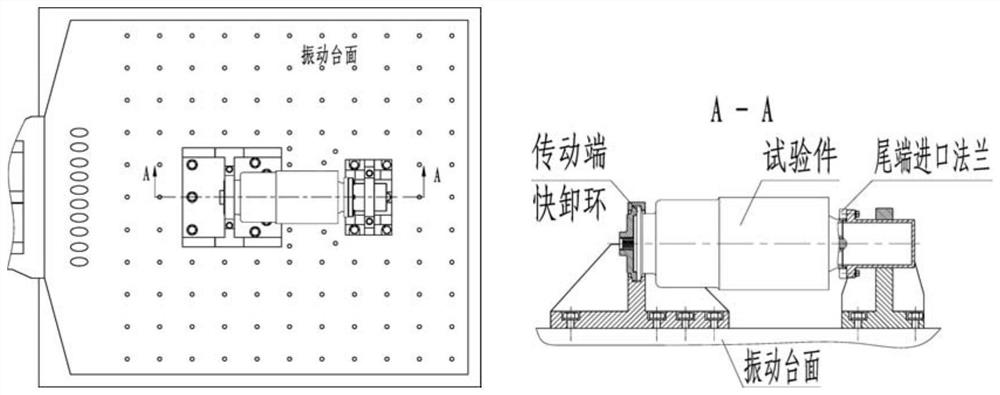

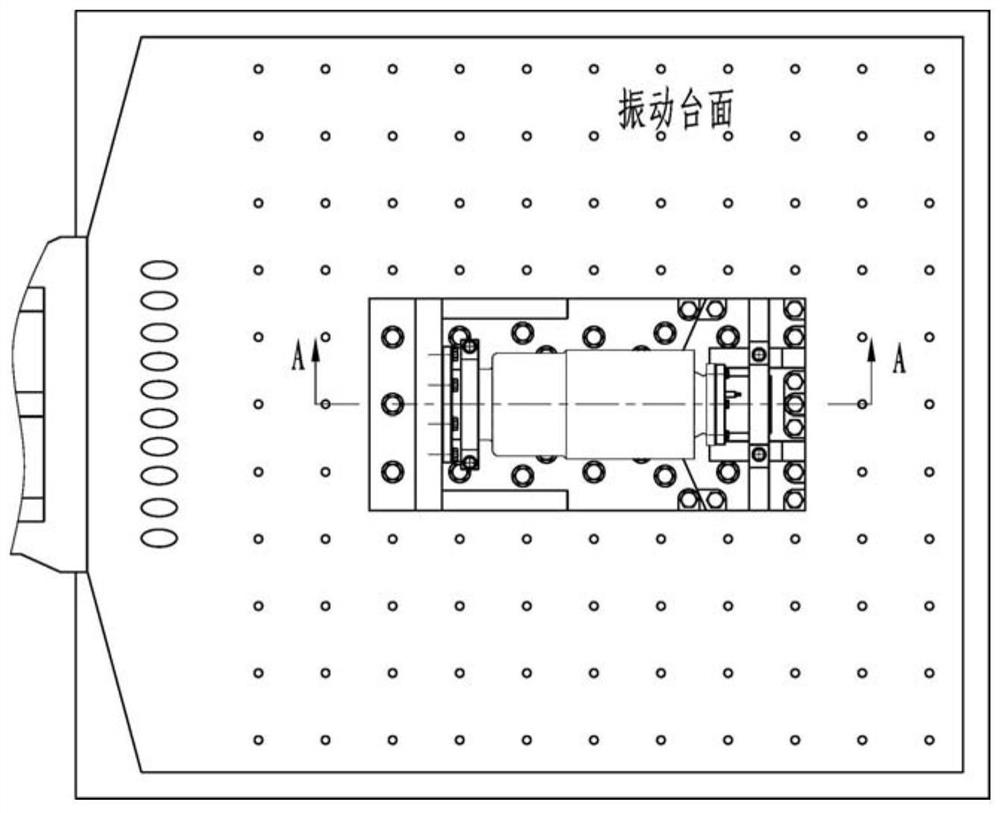

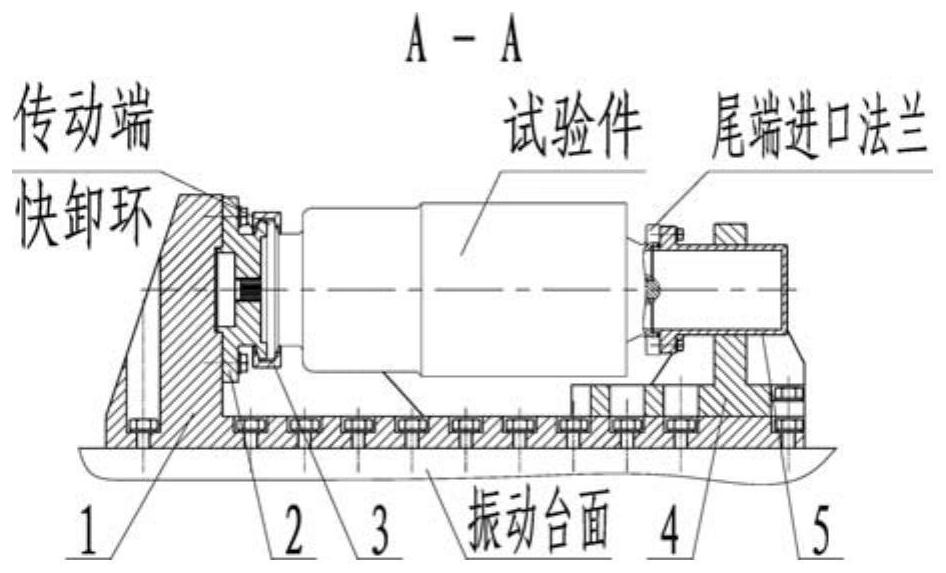

[0025] refer to figure 2 and image 3 , the present embodiment provides an integral vibration fixture for off-line vibration test of a long-axis pump, including a fixture base 1 fixed on the vibrating table with screws; mount 2.

[0026] The positioning pin hole on the mounting base 2 cooperates with the positioning pin of the test piece to fix the axial angle of the test piece after installation; the internal spline on the mounting base 2 is used to brake the drive shaft of the test piece, see Image 6 .

[0027] The integral vibration fixture also includes a tail end support 4 fixed on the fixture base 1 with a threaded protective sleeve and screws, a clamp 3 for fixing the transmission end of the test piece on the mounting seat 2, and an inlet flange fixed at the tail end of the test piece The inlet plug cap 5 on the top; the above inlet plug cap 5 is pressed and fixed by the upper pressure ring of the tail end support 4, see Figure 5 .

[0028] refer to figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com