Radio frequency power supply control method and system applied to etching machine

A technology of radio frequency power supply and control method, which is applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of high etching cost and low etching efficiency of etching machine, and achieve maximum and reduce noise. Interference, achieve the effect of RF power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

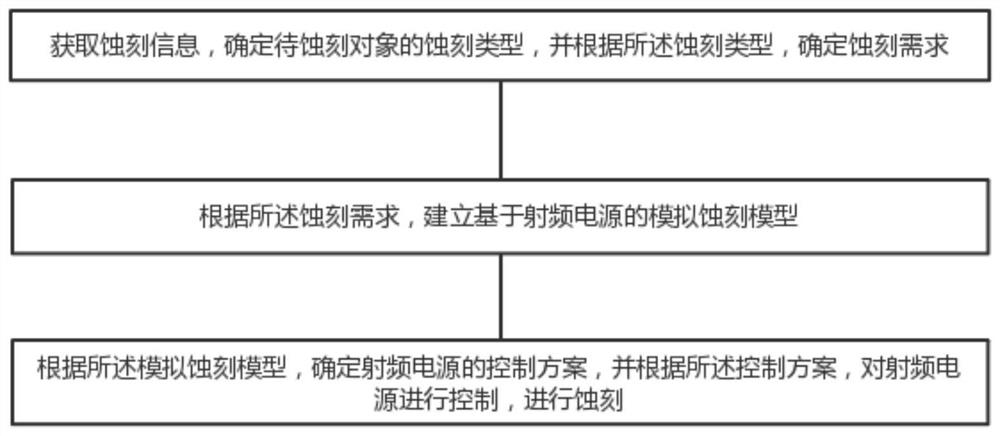

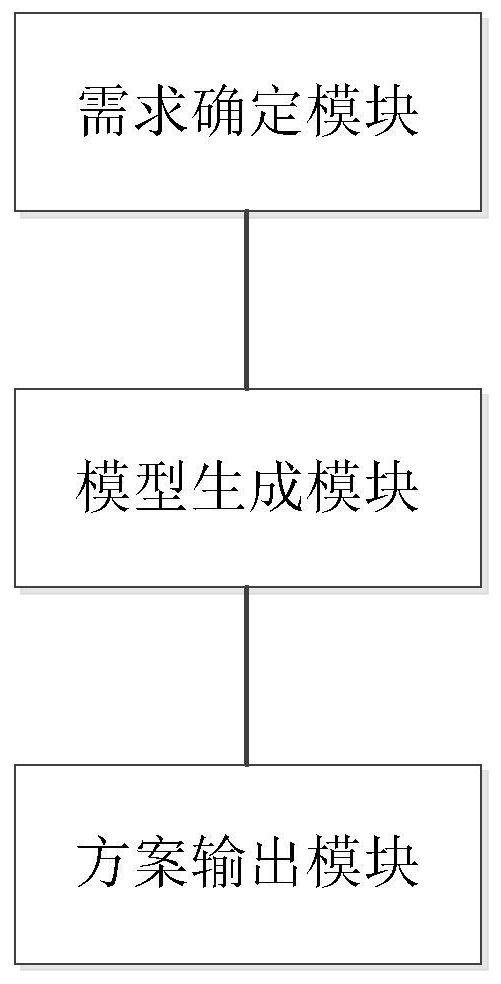

[0069] as attached figure 1 Said, the present invention includes a kind of radio frequency power control method applied to etching machine, comprising:

[0070] Obtain etching information, determine the etching type of the object to be etched, and determine the etching requirement according to the etching type;

[0071] According to the etching requirements, a simulated etching model based on radio frequency power supply is established;

[0072] Determine the control scheme of the radio frequency power supply according to the simulated etching model, and control the radio frequency power supply to perform etching according to the control scheme;

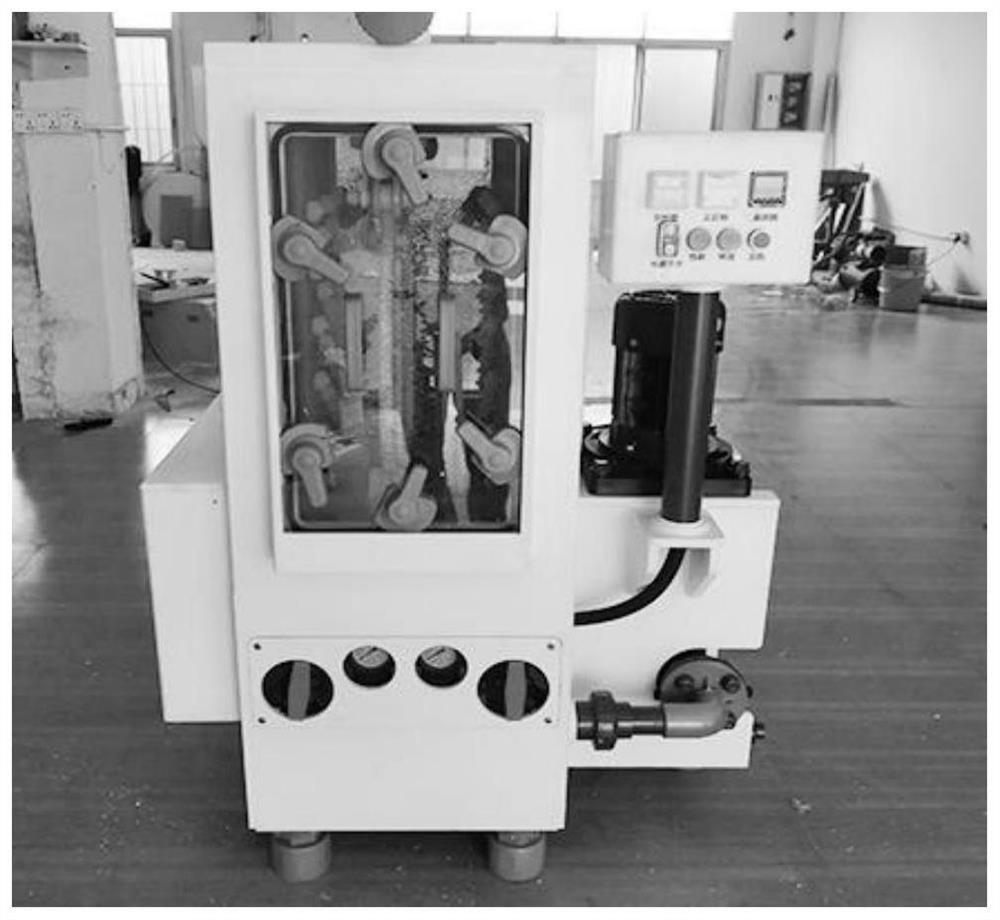

[0073] The working principle of the above technical solution is: in the prior art of the present invention, applying the radio frequency power supply control method to the etching machine requires two radio frequency power supply modules, one of which supplies power to the coil assembly in the etching tank, and the other radio frequ...

Embodiment 2

[0076] In an embodiment of the present invention: said obtaining etching information, determining the etching type of the object to be etched, and determining the etching requirement according to the etching type, includes:

[0077] Acquiring etching information, determining basic parameters of the object to be etched, and determining retrieval information of the object to be etched according to the basic parameters;

[0078] Obtain the etching type and etching process of the object to be etched through the preset etching database according to the retrieval information;

[0079] Analyzing the etching type and etching process of the object to be etched to determine the etching requirements;

[0080] The working principle of the above-mentioned technical solution is: in the prior art of the present invention, when determining the etching demand of the object to be etched, the etching demand is determined by manual input, and it is necessary to wait for the input information befo...

Embodiment 3

[0083] In an embodiment of the present invention: according to the etching requirements, establishing a simulated etching model based on radio frequency power supply, including:

[0084] Obtain historical etching data, determine etching parameters, and use it as training set data;

[0085] Obtain the template etching parameters in the etching database, and use it as test set data;

[0086] Based on the test set data, the training set data is trained to generate a simulated etching model based on a radio frequency power supply.

[0087] The working principle of the above-mentioned technical solution is: in the prior art of the present invention, the application of the radio frequency power control method in the etching machine does not involve the collection and analysis of historical etching data, so there is no simulated etching model based on radio frequency power, which also Although the RF power control method is applied to the etching machine, the etching efficiency is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com