Lead design method and lead structure of 110kV double-winding vehicle-mounted transformer

A design method, 1.110kv technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, inductor/transformer/magnet manufacturing, etc., can solve the problem of small operable space and reduce welding difficulty , Unified position and size, strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them.

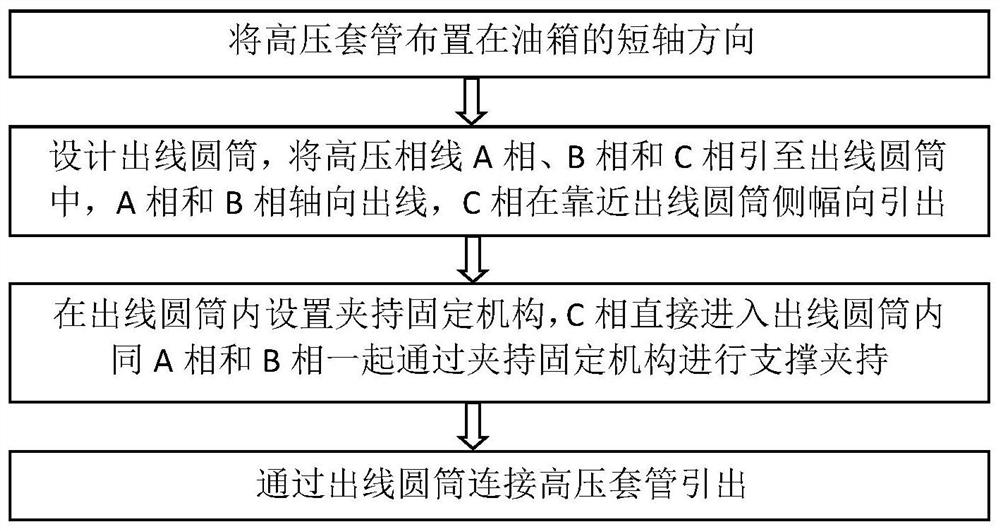

[0024] Such as figure 1 As shown in FIG. 1 , it is a flow chart of the lead design method according to the embodiment of the present invention. A lead design method for a 110kV double-winding vehicle-mounted transformer, comprising the following steps:

[0025] Step 1. Arrange the high-voltage bushing in the direction of the short axis of the fuel tank.

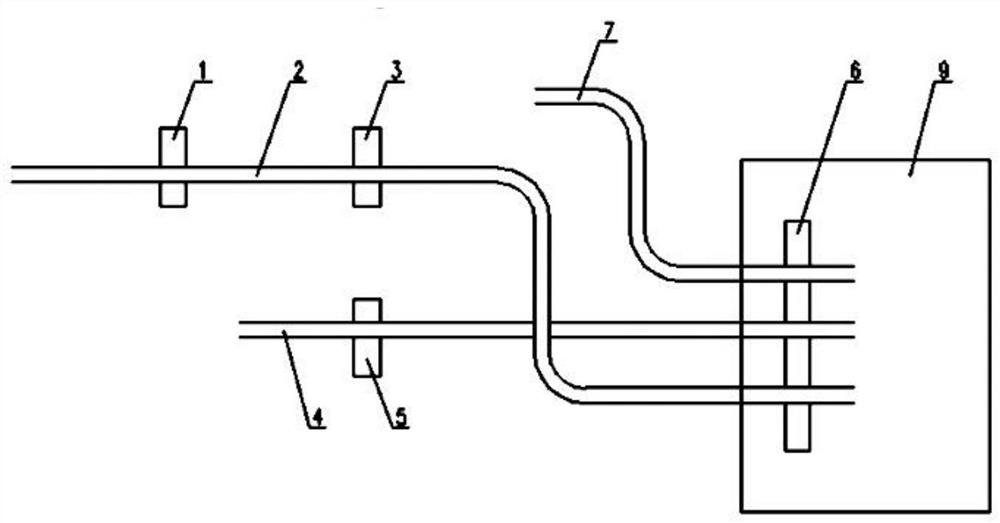

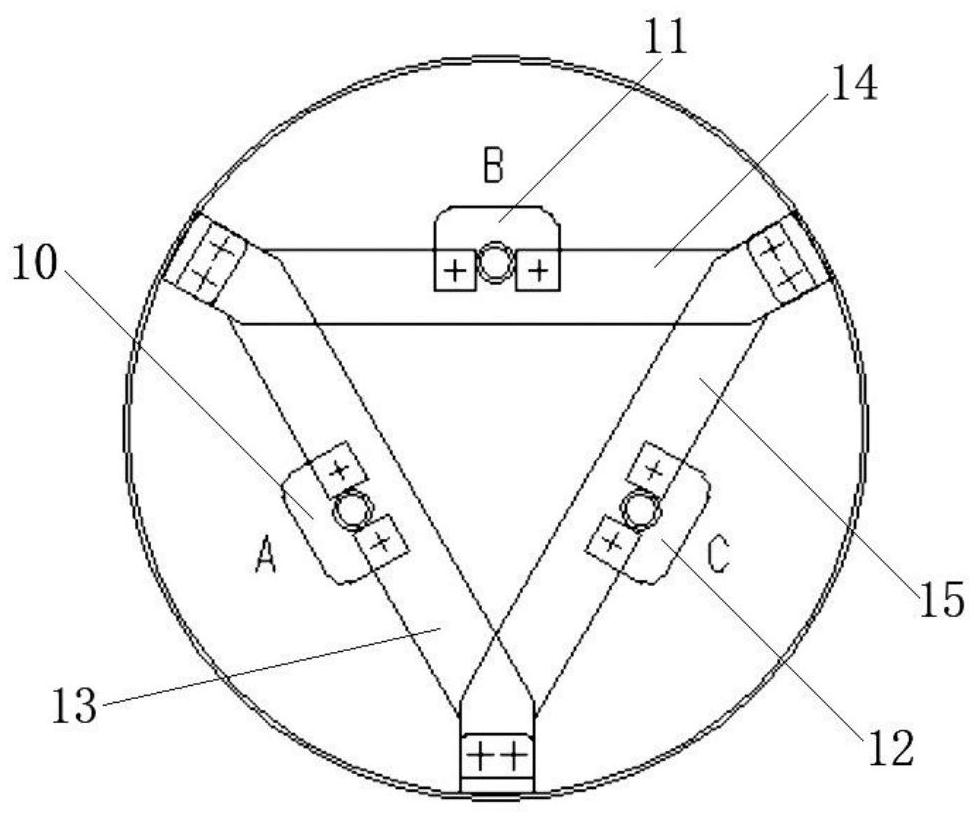

[0026] Step 2. Design the outlet cylinder, lead the high-voltage phase line A phase, the high-voltage phase line B phase and the high-voltage phase line C phase into the outlet cylinder. The wire clamp support clamps the high-voltage phase line A phase and the high-voltage phase line B phase and leads them to the outlet cylinder, and the high-voltage phase line C phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com