Sectional type interval coating pole piece and naked battery cell

A segmented and electrode-layout technology, which is applied to circuits, electrical components, secondary batteries, etc., can solve problems such as potential safety hazards, low volume energy, and performance degradation of battery cells, and achieve optimal high-rate charge and discharge performance, Optimize the transmission path and reduce the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problem solved by the present invention, the technical solution and the technical effects achieved are more clear, and the technical solutions of the embodiments of the present invention will be further described in connection with the accompanying drawings, which will be described in detail. Part of embodiments, not all embodiments. Based on the embodiments of the present invention, those skilled in the art do not have all other embodiments obtained by creative labor, all of which are protected by the present invention.

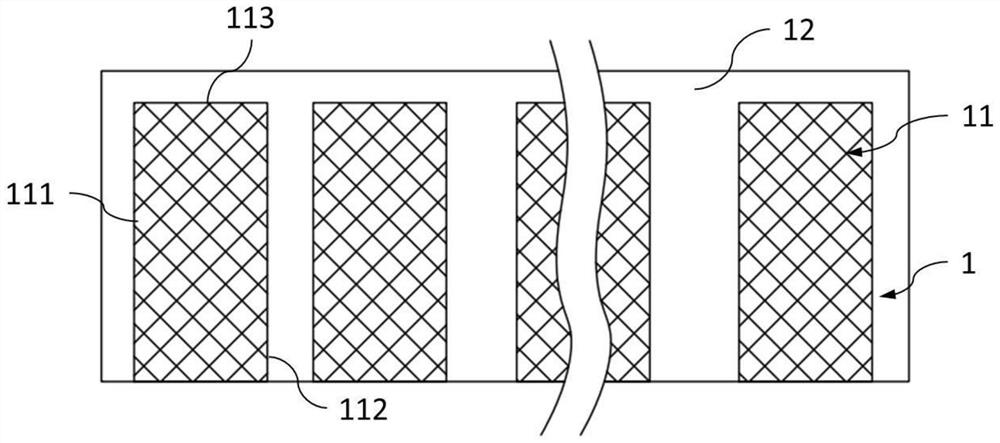

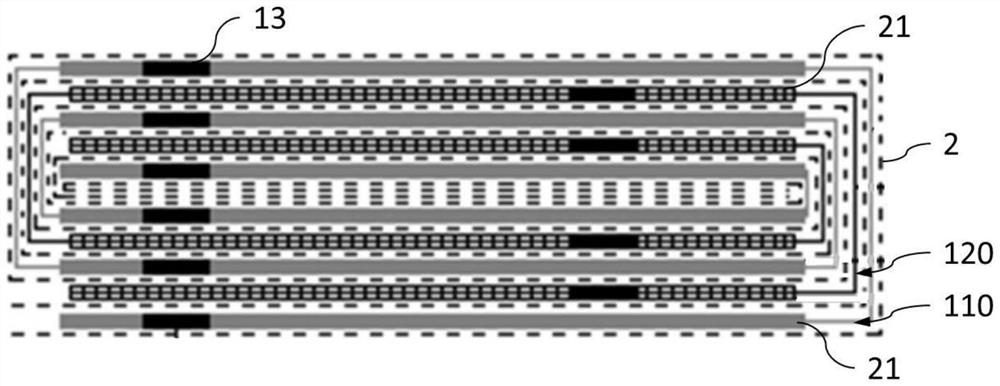

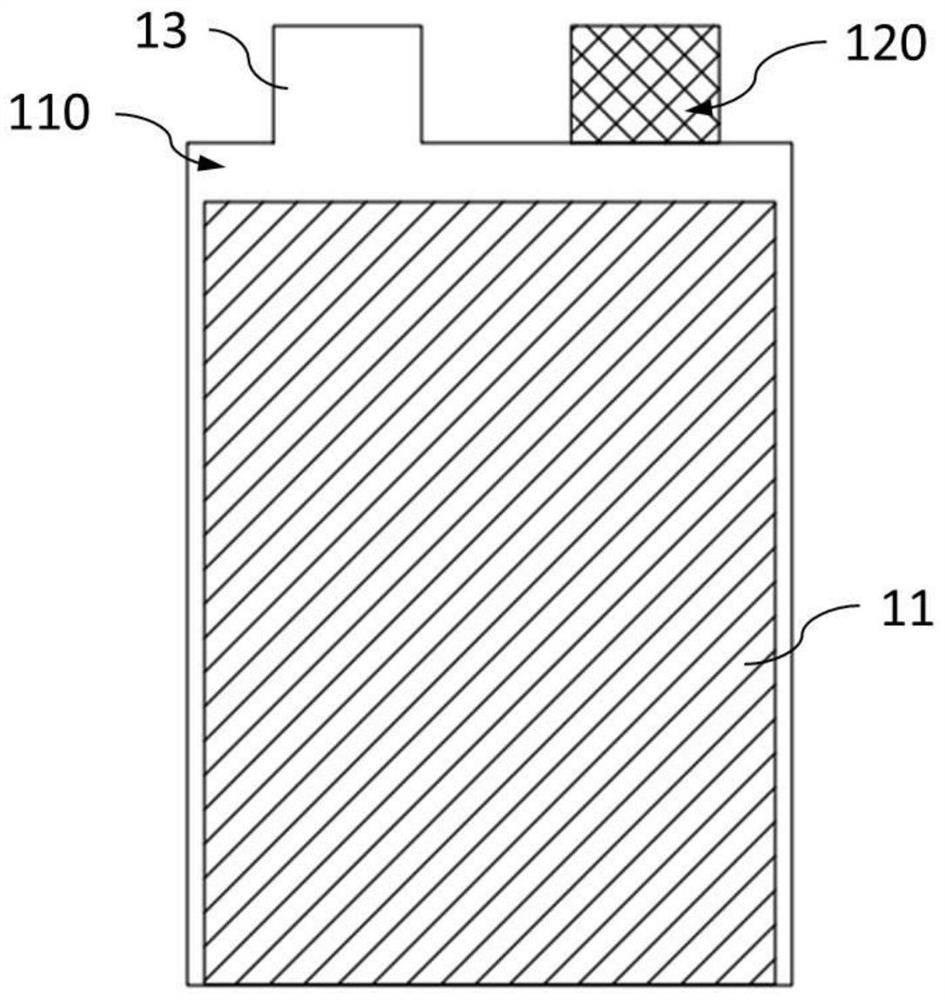

[0033] Such as figure 1 As shown, the present embodiment provides a segmented interval coating plate, which can generally be made into a negative electrode chip 110 or a positive electrode plate 120. The segmented interval coating plate includes a dressing and a current collector 1, and the dressing is coated on the current collector 1, forming a region 11. The material region 11 of the negative electrode chip 110 is configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com