Fish ball forming machine

A technology of forming machine and fish balls, which is applied in fish processing, slaughtering, food science, etc., can solve the problems of affecting product quality, easy to produce defective products, unbalanced feeding pressure, etc., to ensure hygiene, improve quality, and improve feeding The effect of pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

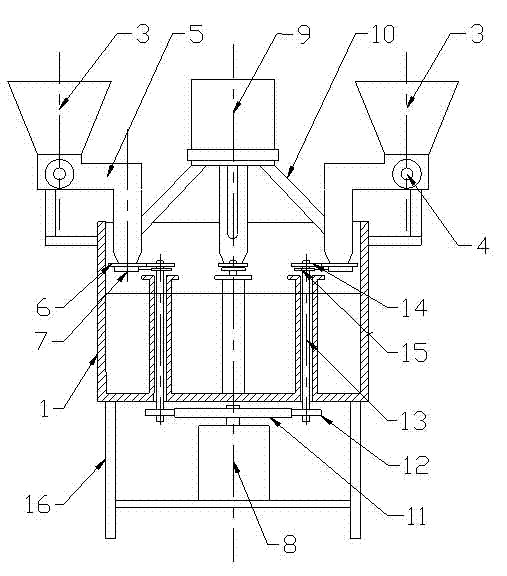

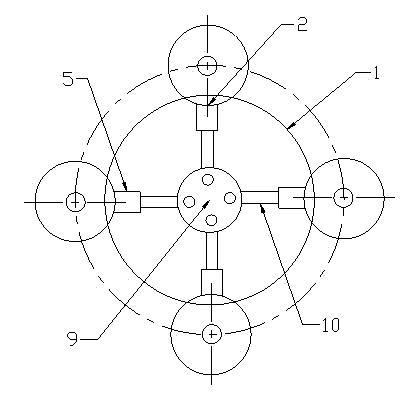

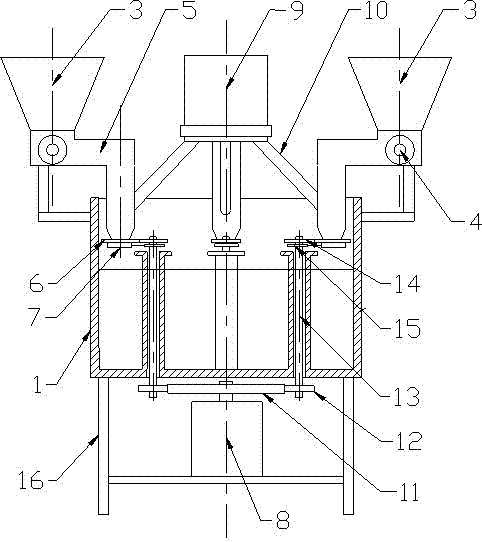

[0010] The fish ball forming machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Following embodiment is an example with 4 fish ball feeding devices, the present invention can also be provided with 6 or 8 fish ball feeding devices.

[0011] The fish ball forming machine of the present invention includes a hot water tank 1 for shaping fish balls, a support 16 is arranged on the bottom side of the hot water tank, and it is characterized in that four fish ball feeders are arranged at intervals around the hot water tank 1 Device 2, the fish ball feeding device 2 is composed of a feed hopper 3 provided above the circumference of the hot water tank 1, a feeding pump 4 and a turning-shaped feeding channel 5, the feeding pump 4 is a vane pump, and the turning-shaped The discharge port below the feeding passage 5 is provided with a pill rubbing device 6 and a shearing forming device 7 in seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com