Upward cutting and energy-saving inner circle slicing machine with single tool bit

A technology of inner circle slicing and cutter head, which is applied in the field of single cutter head energy-saving inner circle slicer, which can solve the problems of low cutting efficiency, high energy consumption, and low yield, so as to improve cutting precision, prevent knife burning, and avoid material drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] The internal circle slicer uses a high-speed rotating stainless steel thin tension blade to cut hard and brittle materials, and sprays cooling and lubricating fluid at the cutting place for forced cooling, lubrication and chip removal. The workpiece feed relies on the main motor to achieve constant tension feed and index feed It is precisely fed by a high-resolution stepping motor, and the cutting thickness and precision are controlled by a PC microcomputer for automatic cycle control.

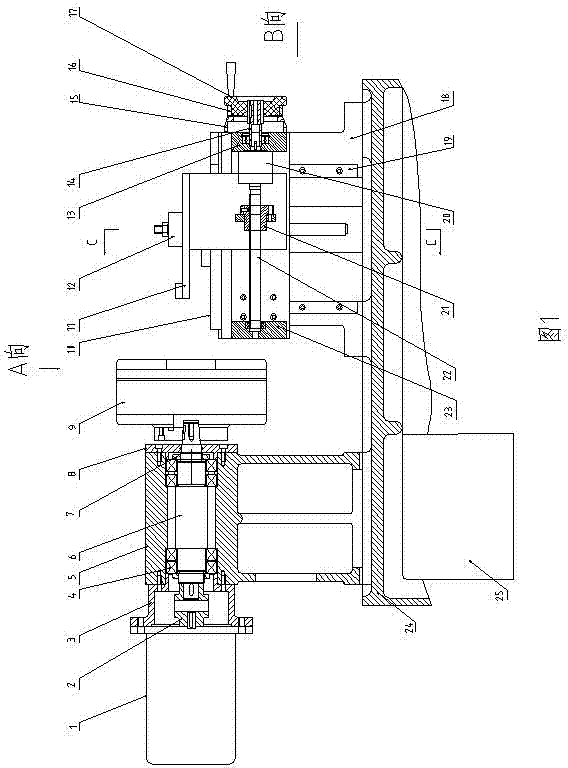

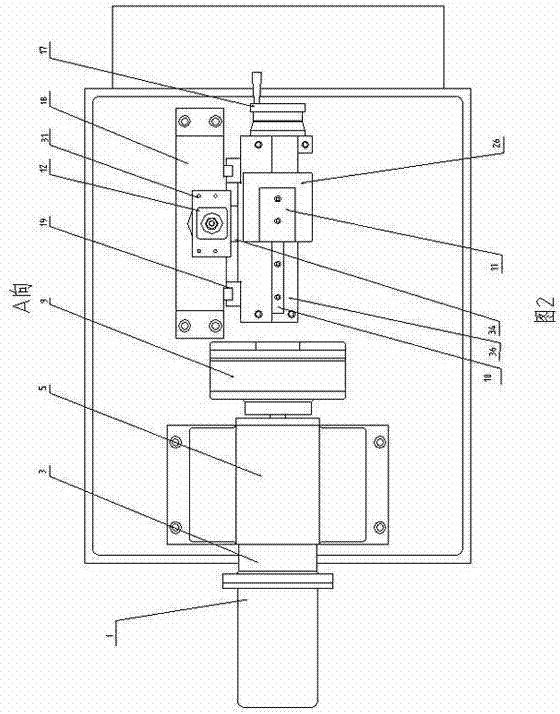

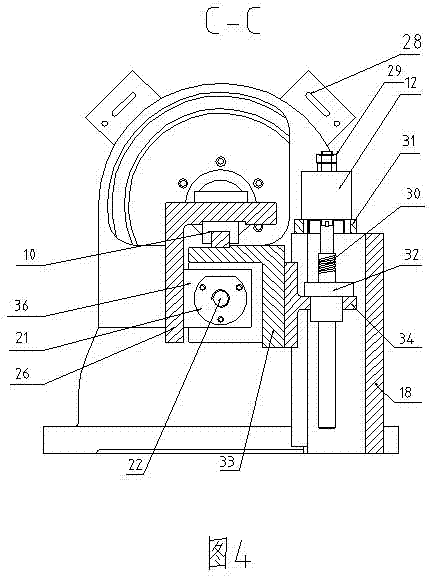

[0012] see figure 1 Shown, the upper left part of the cabinet 24 is provided with a cutting drive, and the right part is provided with a horizontal feeding device and a vertical elevating mechanism. The energy-saving assembly of the present invention is composed of frequency conversion speed regulator 25, main motor 1, shaft coupling 2 and PC microcomputer control system. The main m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com