Vacuum cleaner nozzle incorporating first suction head and second suction head

A technology of vacuum cleaners and suction ports, which is applied in the directions of vacuum cleaners, suction nozzles, household appliances, etc., can solve the problems such as the inability to provide suction nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] In the following description, the vacuum cleaner nozzle is referred to as a nozzle.

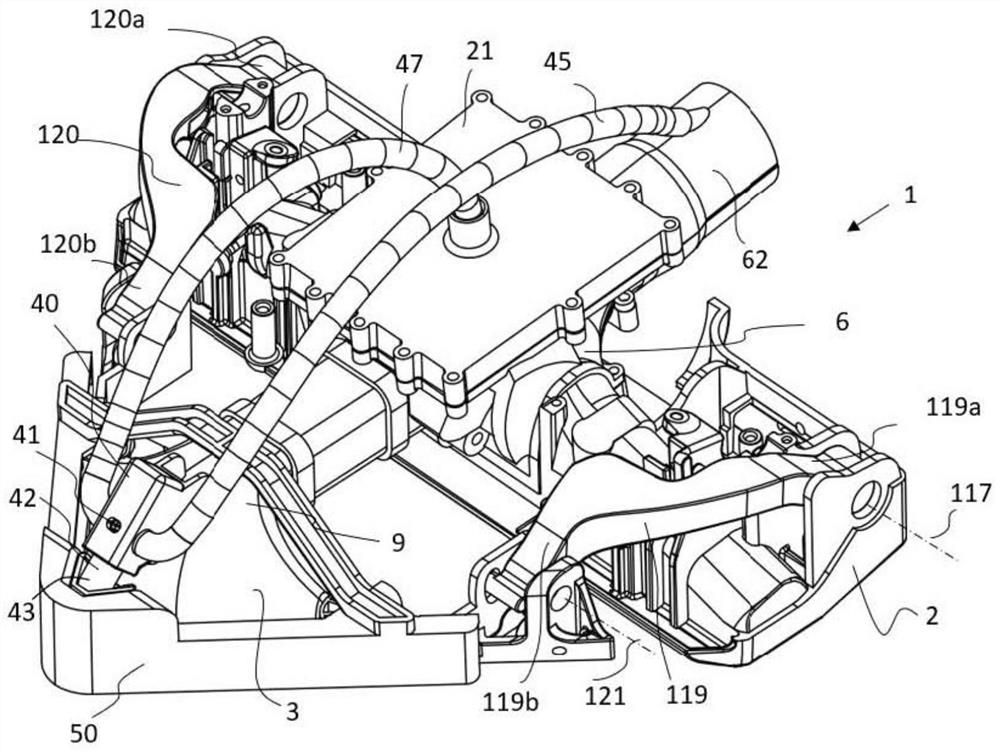

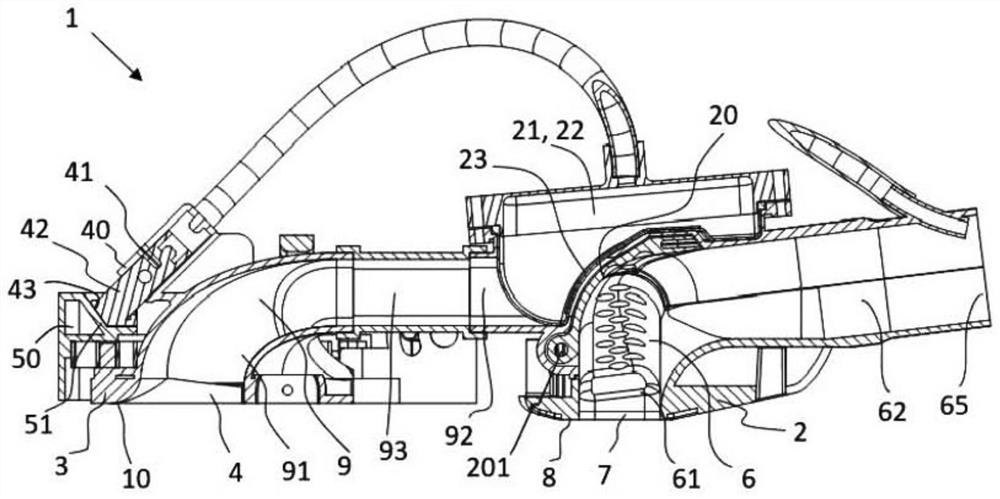

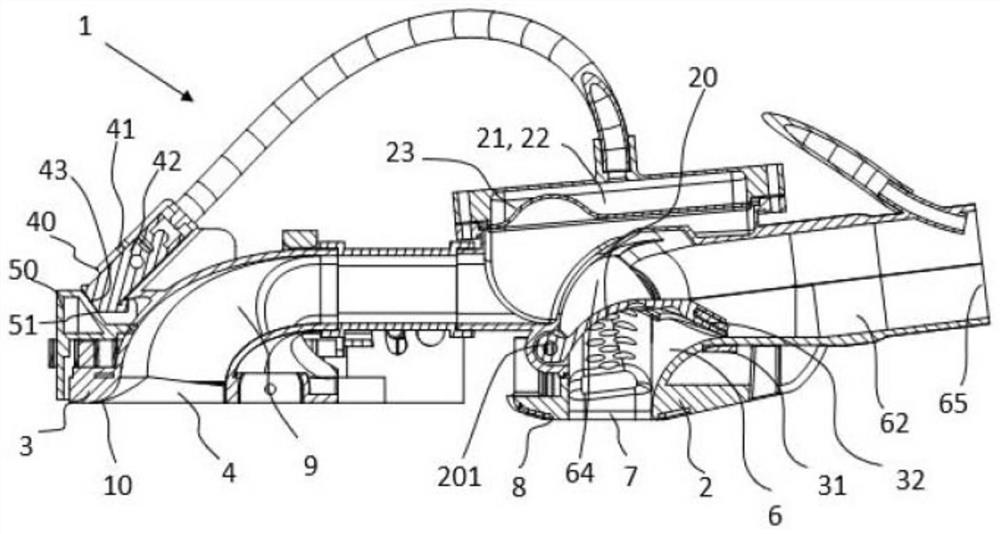

[0096] exist figure 1 In this case, the suction nozzle 1 comprises a first head 2, advantageously constituted by a rectangular head, and a second head 3, advantageously constituted by a triangular head. The second head 3 defines a pointed shape, which includes a suction opening 4, which can also be triangular in shape, so that the suction nozzle 1 can more easily reach the corner of the room or stand along the skirting line. Vacuum surfaces. The suction opening 4 leads to the lower surface 10 of said second head 3 .

[0097] During the process of vacuuming the surface, the suction nozzle 1 is moved back and forth or oppositely. The suction nozzle moves forward when pushed, and moves backward when pulled by, for example, a handle (not shown) integral with a suction pipe (not shown) attached to the suction nozzle 1 . The one or more leading edges of the nozzle define the front of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com