Full-automatic solid-phase organic synthesis modular equipment

An organic synthesis and modular technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as no functional settings, limited applications, and inability to carry out chemical reactions, etc., to achieve easy Easy to operate and switch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

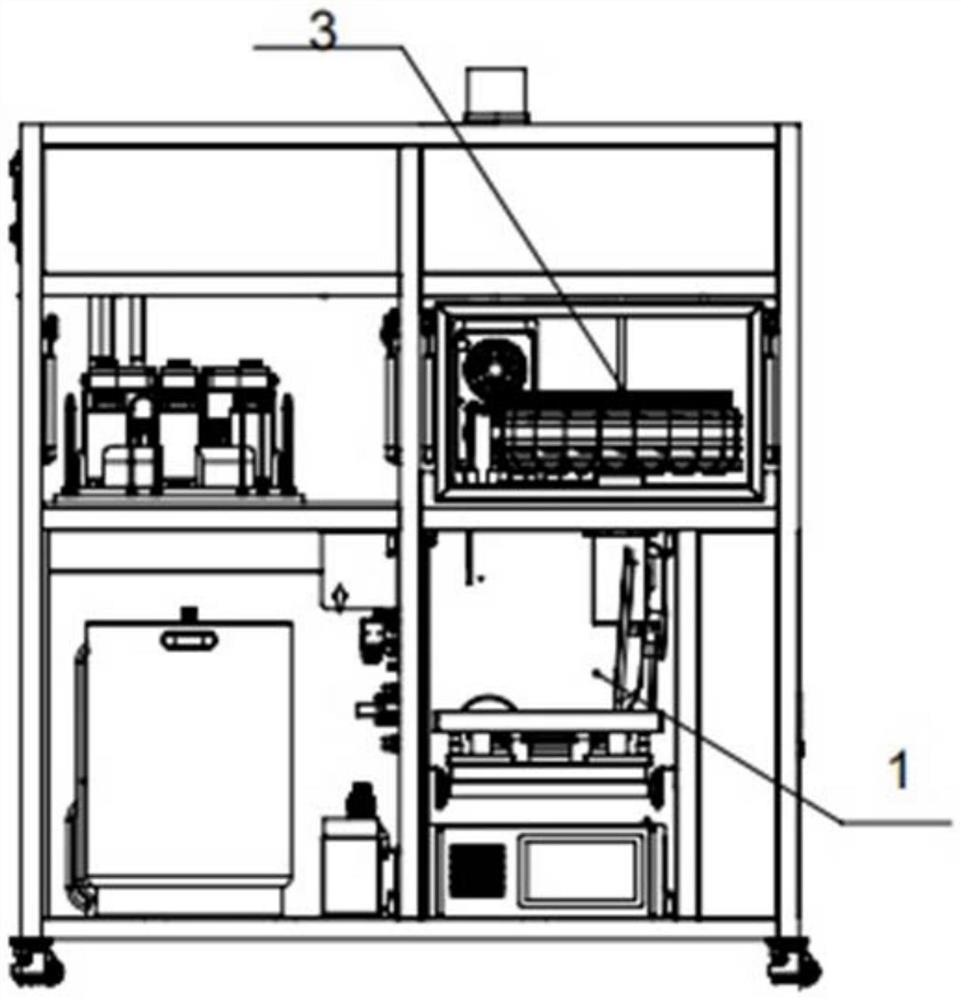

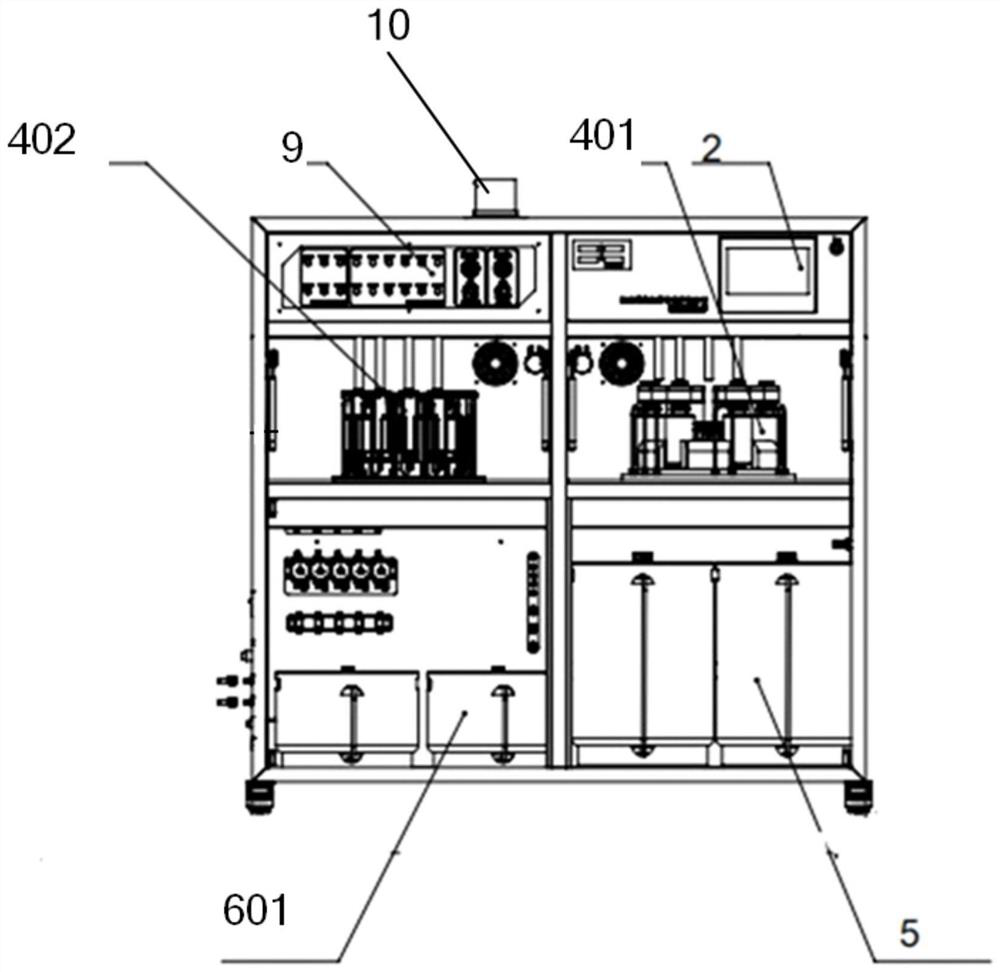

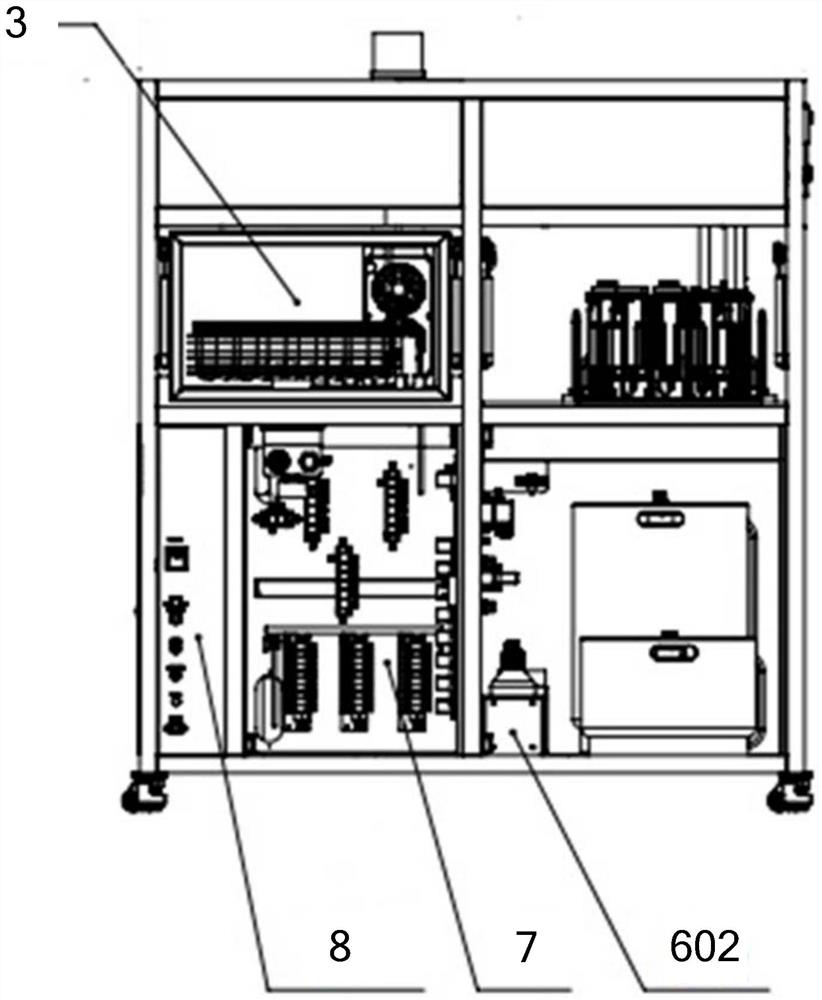

[0059] Such as Figure 1-5 As shown, the present embodiment provides a kind of fully automatic solid-phase organic synthesis modularized equipment, and the equipment consists of an external frame, a reactor module located in the external frame, a reaction reagent preparation module 3, a first solvent module 601, and a second solvent module 602. Valve module 7, electronic device module 8, equipment control and data recording module 1, gas and temperature regulation module 9, waste liquid collection module 5, and connecting pipelines. The device also includes an exhaust port 10 arranged on the outer frame and the top of the device, and the exhaust port 10 is used for exhausting exhaust gas generated in the device.

[0060] The equipment control and data recording module 1 is connected to the electronic device module 8, and the electronic device module 8 is connected to the reaction reagent preparation module 3, the first solvent module 601, the second solvent module 602, the gas...

Embodiment 2

[0068] This embodiment relates to a solid-phase organic synthesis modular equipment; the equipment is a system capable of synthesizing 20-50 g (5 mmol-20 mmol) solid-phase carriers on a pilot scale.

[0069] 1. External framework:

[0070] The external frame is used to support the reactor module, the reagent preparation module and the solvent module, etc.

[0071] Such as figure 1 As shown, the equipment system adopts a vertical structure, the upper layer of the shelf is a touch screen 2, a gas and temperature adjustment module 9, the top is an exhaust port 10, and the middle layer is placed with the first reactor module 401, the second reactor module 402, and the reaction reagents The preparation module 3; the waste liquid collection module 5, the first solvent module 601 and the second solvent module 602 are placed in the lower layer, and the equipment control and data recording module 1 is in the rear position of the lower layer. The frame structure can be made of other h...

Embodiment 3

[0091] This embodiment relates to a solid-phase organic synthesis modular equipment; the equipment is able to synthesize 1g-5g (0.25mmol-2.0mmol) solid-phase carrier in laboratory scale.

[0092] 1. External framework:

[0093] The external frame is used to support the reactor module, the reagent preparation module and the solvent module, etc.

[0094] Such as figure 1As shown, the equipment system adopts a vertical structure, the upper layer of the shelf is a touch screen 2, a gas and temperature adjustment module 9, the top is an exhaust port 10, and the middle layer is placed with the first reactor module 401, the second reactor module 402, and the reaction reagents The preparation module 3; the waste liquid collection module 5, the first solvent module 601 and the second solvent module 602 are placed in the lower layer, and the equipment control and data recording module 1 is in the rear position of the lower layer. The frame structure can be made of other hard materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com