Multi-channel reaction kettle heating furnace

A heating furnace and reactor technology, applied in the field of multi-channel reactor heating furnace, can solve the problems of low experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

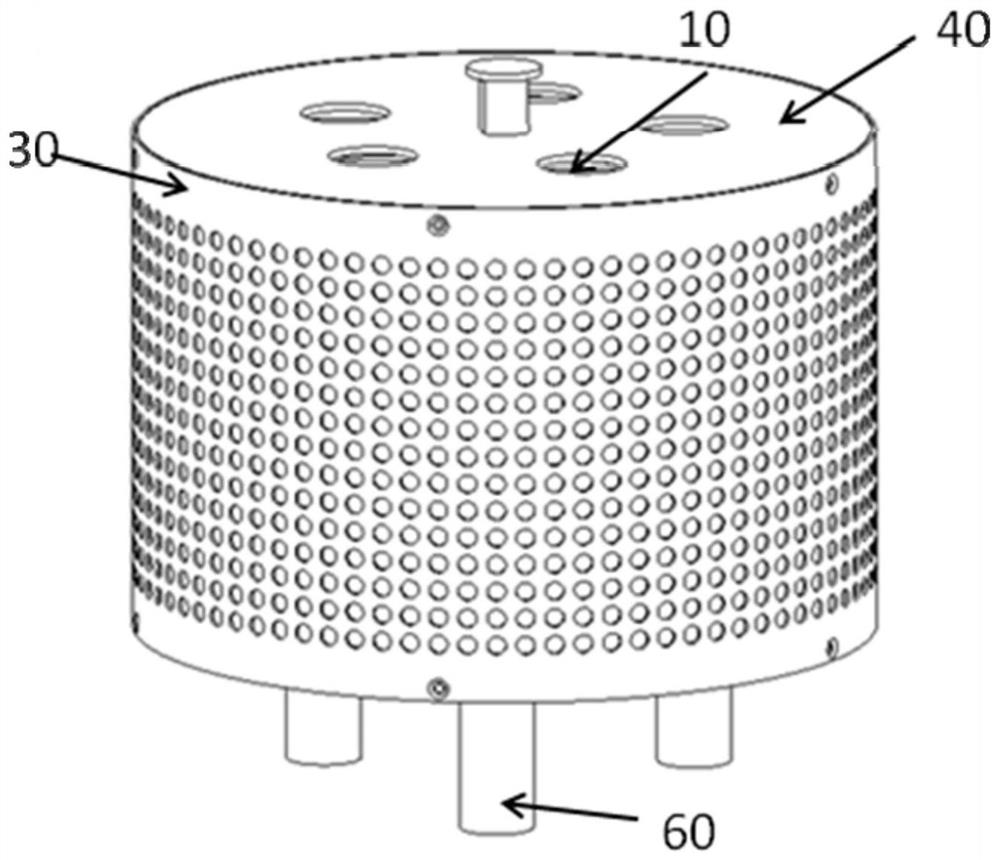

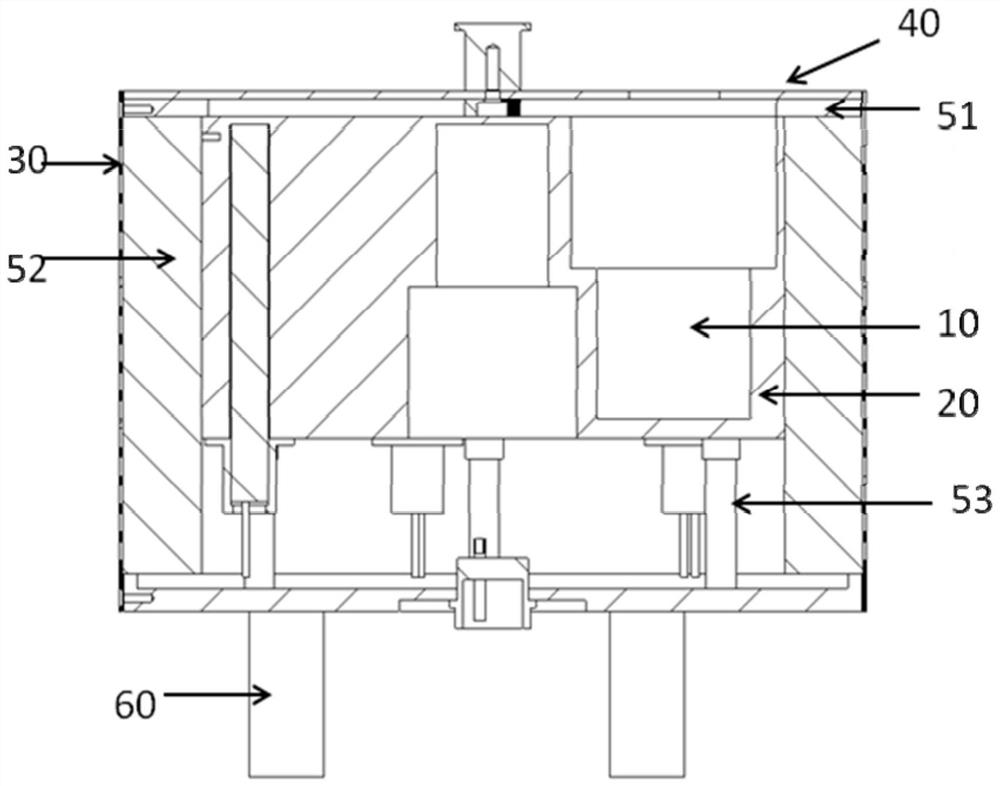

[0031] A multi-channel reactor heating furnace, which includes a heating channel (10), the heating channel (10) is set to provide a heating space for the reactor; a heating element (20), the heating element (20) is arranged on the the outside of the heating channel (10), so as to heat the heating channel (10); a shell (30), the heating channel (10) and the heating element (20) are arranged in the shell (30); A cover (40), the cover (40) is detachably connected to the casing (30) in a sealed manner. There are more than one heating channel (10). The heating element (20) is arranged to surround the outside of the heating channel (10), so as to heat different positions of the heating channel (10), and the heating element (20) adopts a high thermal conductivity aluminum alloy inner core. The casing (30) is configured as a porous structure to increase the heat dissipation rate and reduce the temperature of the casing (30). The casing (30) is respectively fixed to the first heat ins...

Embodiment 2

[0035] A multi-channel reaction kettle heating furnace is provided with a heating channel (10) inside, which can accurately match the appearance size of a standard reaction kettle on the order of 1 liter; there are three heating channels (20) evenly distributed between the heating element (20) and the outer shell The third heat insulating member (53) between the bottom of (30), in order to play the role of separation between the bottom of the shell (30) and the heating element (20) and the fixed connection between the parts; the shell (30) Three evenly distributed support parts (60) are provided on the outside of the bottom.

Embodiment 3

[0037] A multi-channel reaction kettle heating furnace is provided with 8 heating channels (10) inside, which can accurately match the appearance size of a standard reaction kettle on the order of 5 milliliters; the interior is provided with a heating part (20) and the outer shell ( 30) between the bottom of the third insulation (53), in order to play the role of separation between the bottom of the shell (30) and the heating element (20) and the role of fixed connection between the parts; the bottom of the shell (30) There are 4 evenly distributed support parts (60) on the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com