An inorganic powder material synthesis device

A technology of inorganic powder materials and synthesis devices, which is applied in the fields of combination devices, dispersed particle filtration, lighting and heating equipment, etc., can solve the problems of harsh process conditions, unsatisfactory mixing and coating effects, and complicated process steps, and achieves high performance. The effect of powder collection efficiency, stable air pressure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

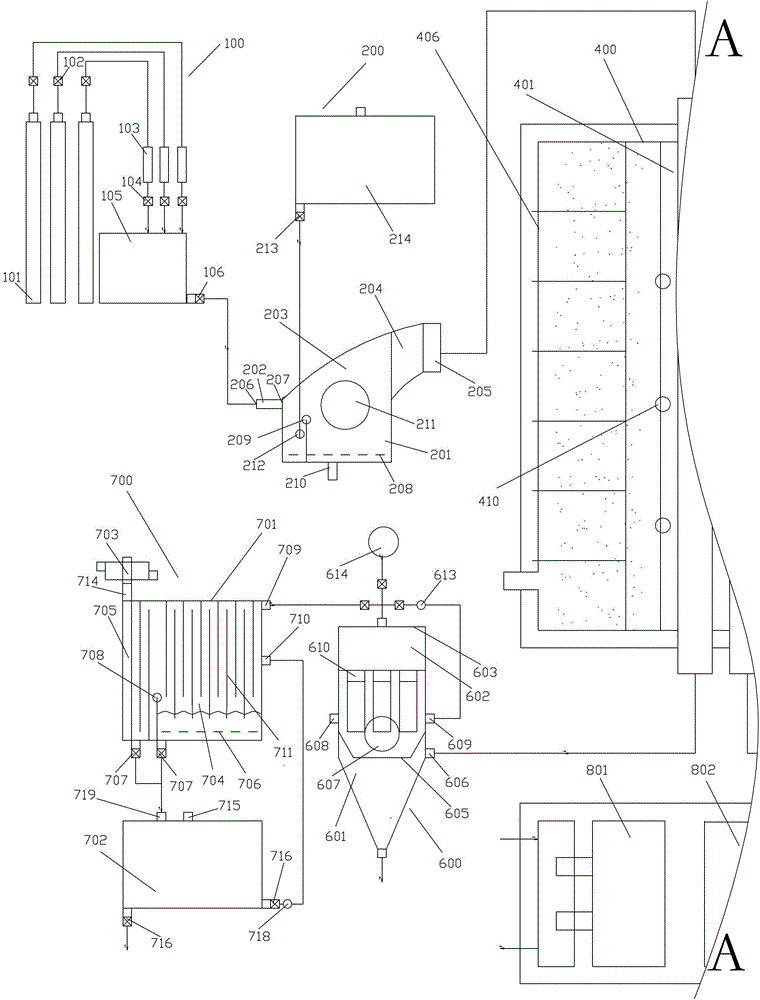

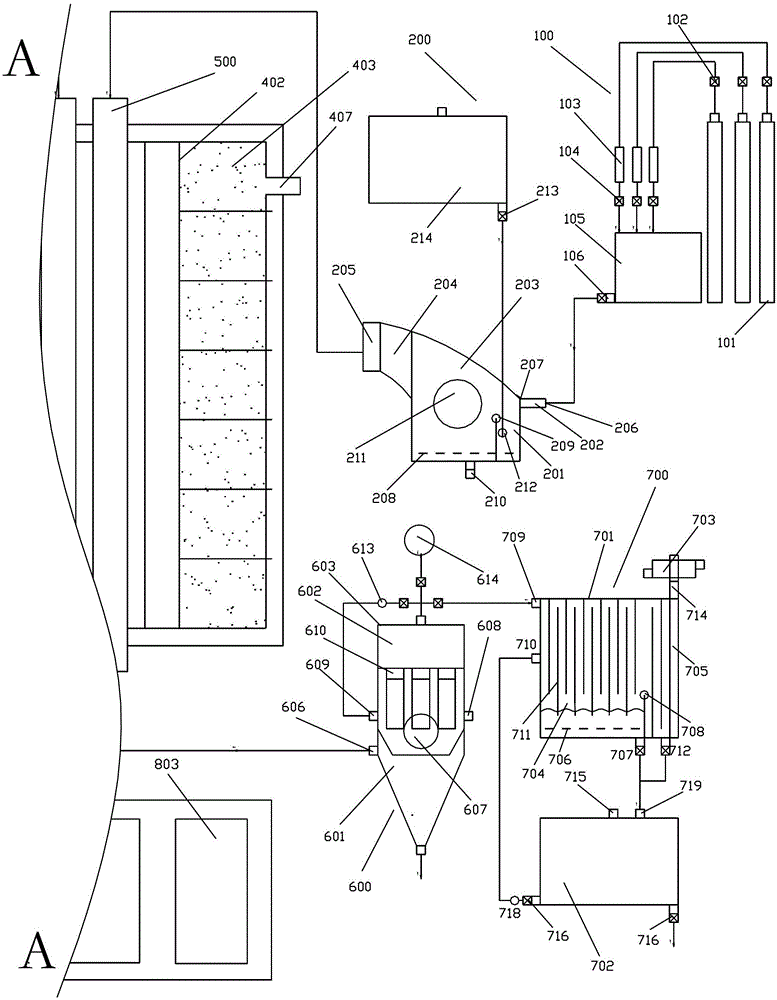

[0049] image 3 It is a schematic diagram of the left half of the inorganic powder material synthesis device of the second embodiment of the present invention with B-B as the fracture surface, Figure 4 It is a schematic diagram of the right half of the inorganic powder material synthesis device in Example 2 of the present invention with B-B as the fracture surface. ,Such as image 3 , Figure 4 as shown,

[0050] The device consists of raw and auxiliary material supply system, reaction system, collection system, tail gas treatment system and electrical control system.

[0051] The device in this embodiment has the same parts and symbols as those in the first embodiment, and the description of the device is omitted in this embodiment.

[0052] Compared with Embodiment 1, this embodiment mainly has the following differences:

[0053] The raw material supply system includes a gas raw material supply device, a solid raw material supply device and a liquid raw material supply...

Embodiment 3

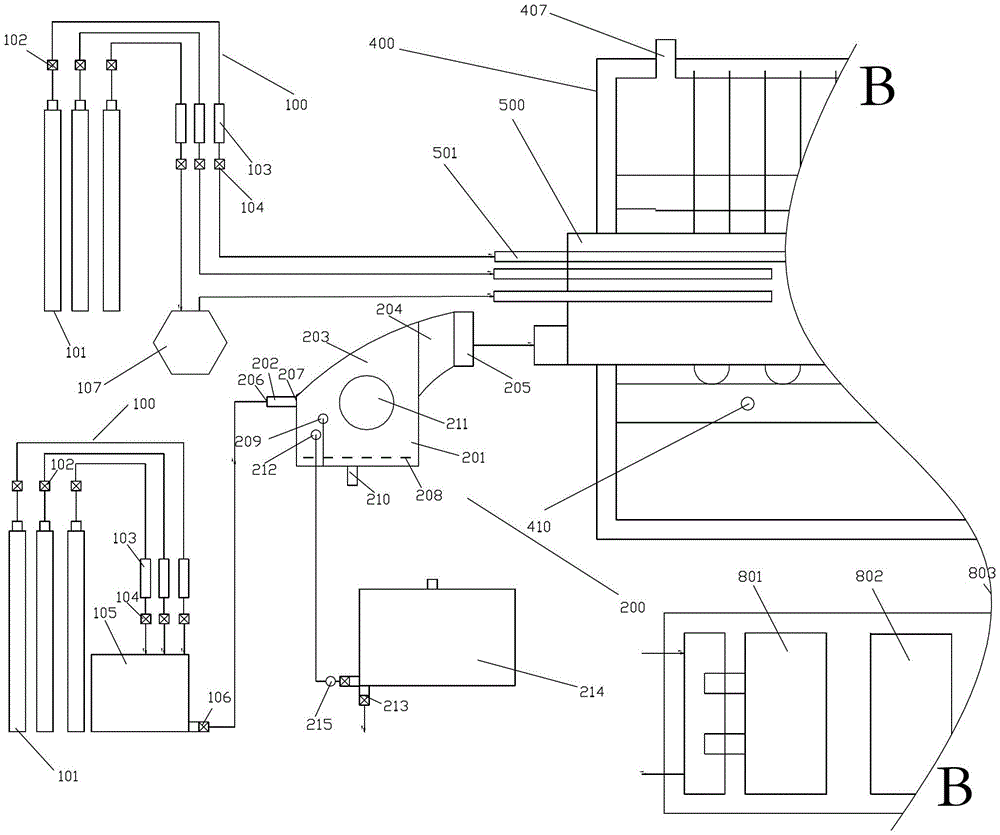

[0058] Figure 5 It is a schematic diagram of the left half of the inorganic powder material synthesis device of the third embodiment of the present invention with C-C as the fracture surface, Image 6 It is a schematic diagram of the right half of the inorganic powder material synthesis device in Example 3 of the present invention with C-C as the fracture surface, as shown in Figure 5 , Image 6 as shown,

[0059] The device consists of raw and auxiliary material supply system, reaction system, collection system, tail gas treatment system and electrical control system.

[0060] The device in this embodiment has the same parts and symbols as those in the first and second embodiments described above, and the description of this embodiment is omitted.

[0061] Compared with embodiment one and embodiment two, this embodiment mainly has the following differences:

[0062] The sintering furnace 400 adopts a tilting structure (the angle between the central axis of the sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com