Steel heat-insulation fireproof door angle grinder capable of continuously grinding fillets

A technology of grinder and angle grinder, which is applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc. It can solve the problems of inconvenient portability and transportation of fire doors, difficulty in determining the grinding angle, and inability to adjust the angle, etc. problem, to achieve the effect of convenient portability, high precision, stable and continuous grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

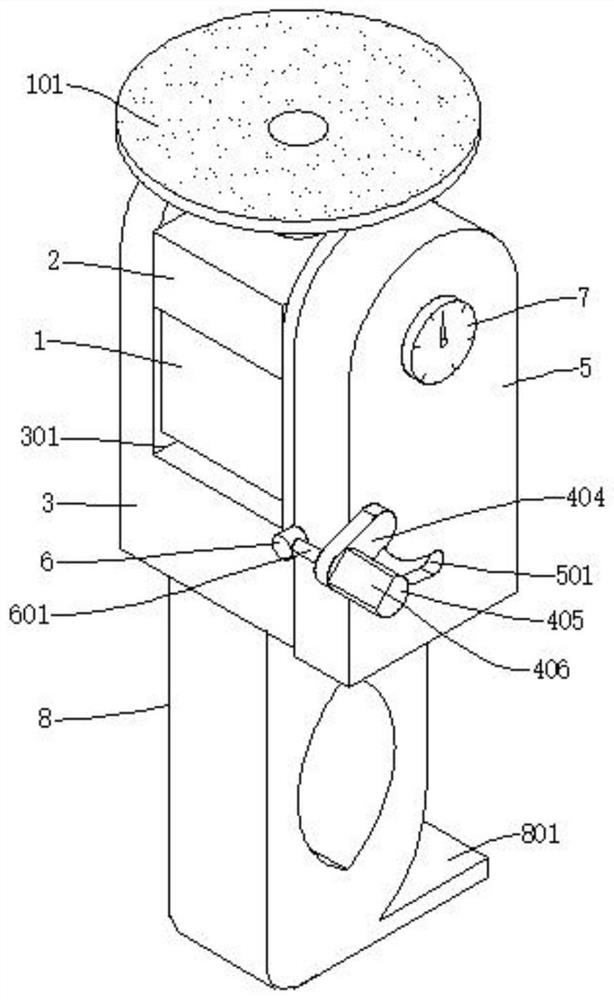

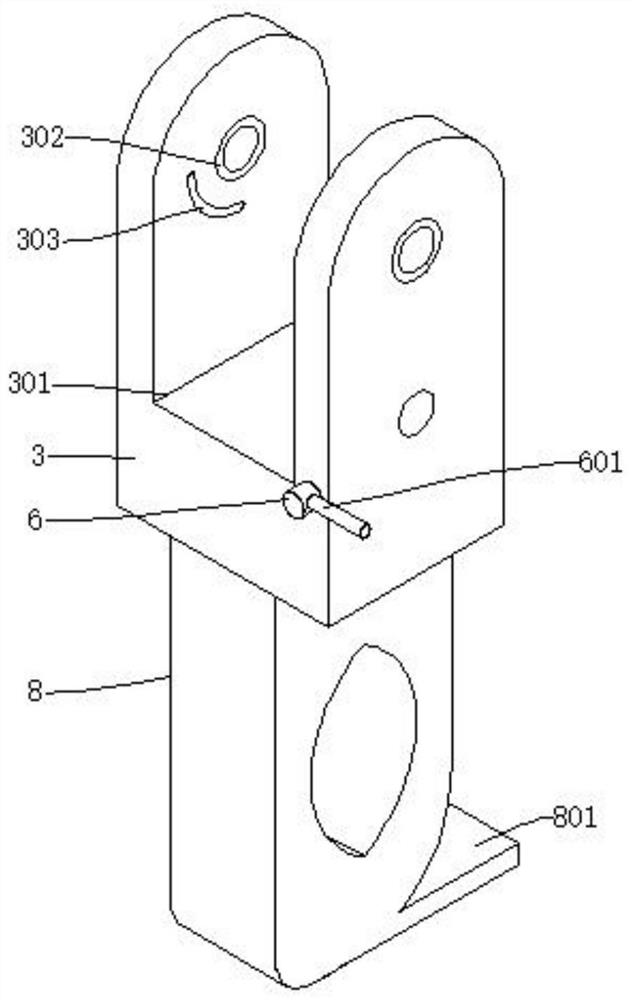

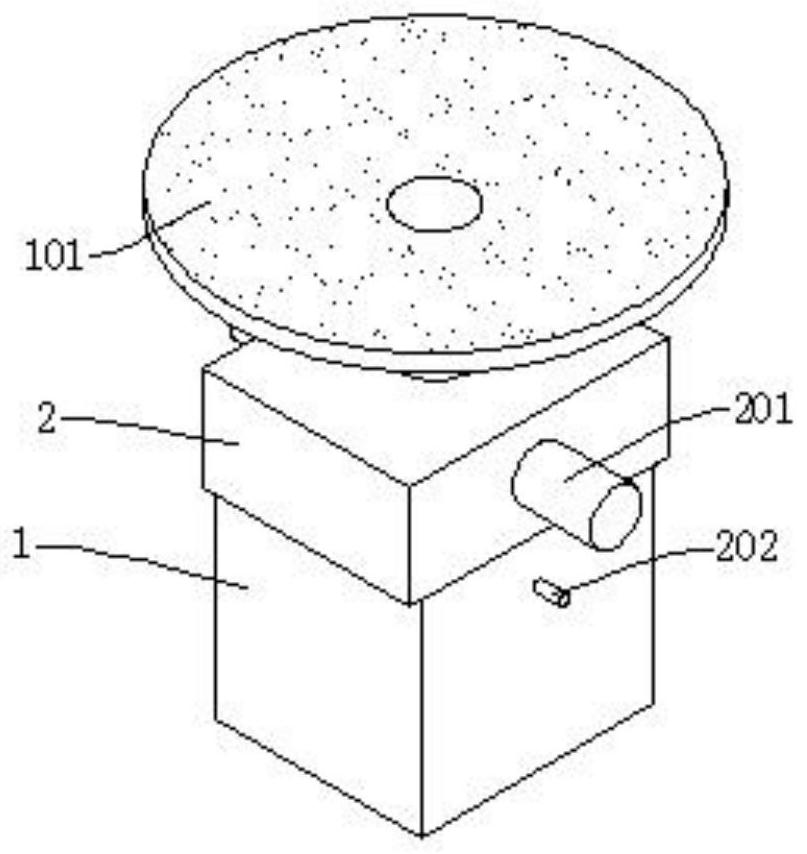

[0026] Such as figure 1 with image 3 As shown, an angle grinder for steel heat-insulated and fire-proof doors that can continuously grind rounded corners includes an angle grinder body 1 and a grinding wheel 101, and the grinding wheel 101 is movably installed on the output shaft above the angle grinder body 1 Above, the upper end of the angle grinder body 1 is threadedly fixed with a connecting cover 2 , and there is an integrally formed connecting column 201 in the middle of the left and right sides of the connecting cover 2 , and the angle grinder body 1 is installed on the In the installation groove 301 of the support base 3, the two connecting columns 201 are movably installed in the installation groove 301 through the bushing 302, and the connecting column 201 on the right side extends out of the support base 3 and is connected with an angle adjustment mechanism 4 on the right side, The outer side of the angle adjustment mechanism 4 is covered with a protective case 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com