Movable pneumatic manipulator

A pneumatic manipulator and mobile technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of affecting the accuracy of grasping objects and affecting work efficiency, and achieve the effect of facilitating movement and position adjustment, reducing cost and execution difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

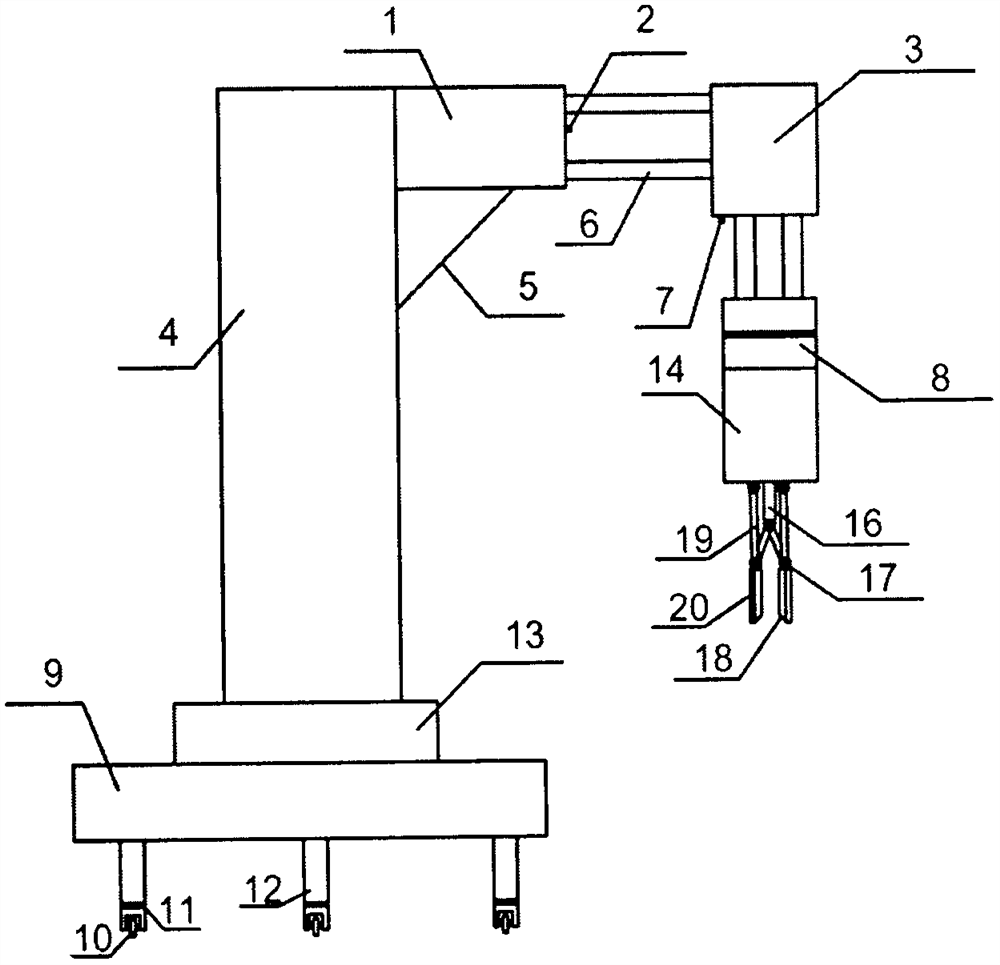

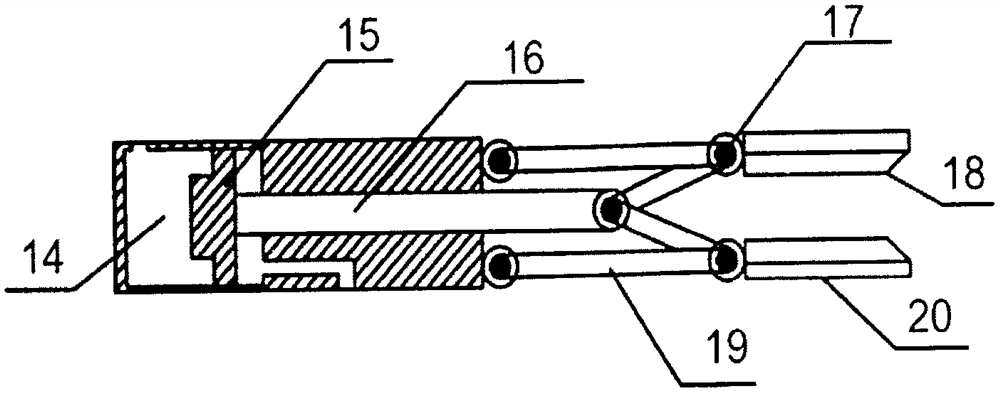

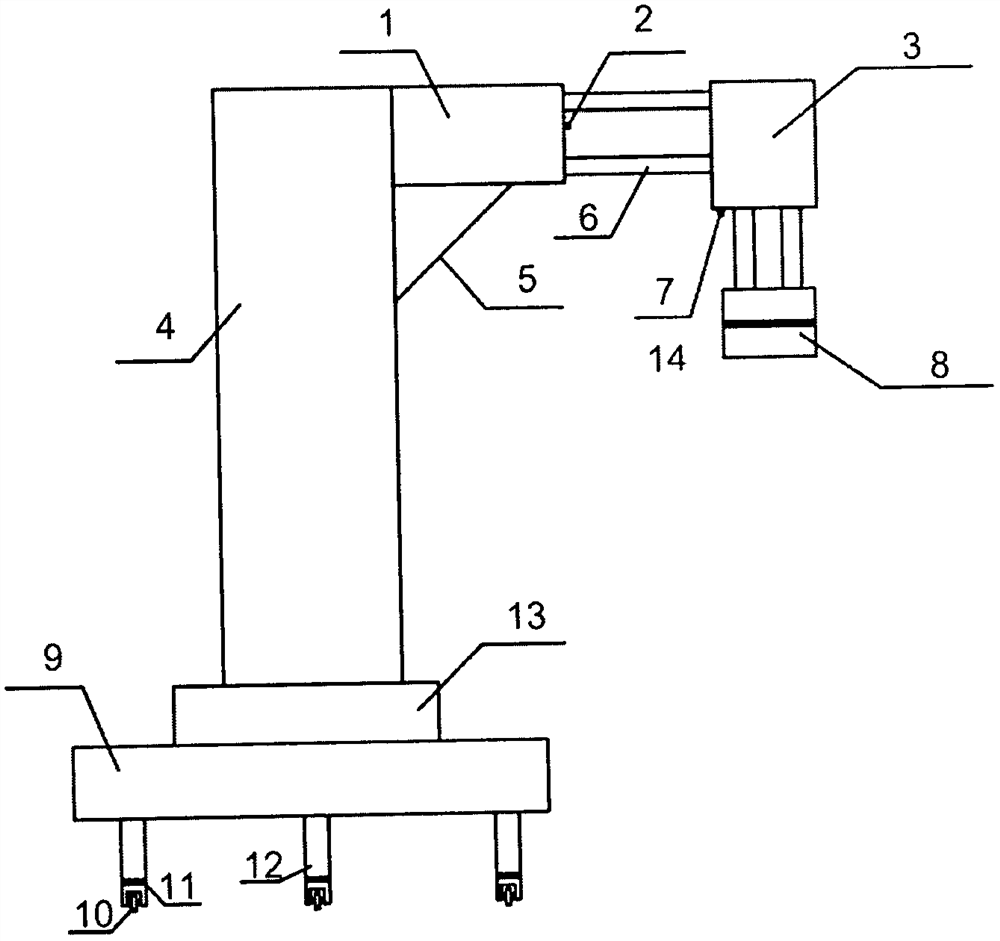

[0021] Such as figure 1 A movable pneumatic manipulator is shown, which includes a mechanical claw linkage part and a mechanical claw placed on the linkage part. The mechanical claw linkage part is provided with a wheel bracket 12, a wheel 10, a load-carrying chassis 9, a rotating bearing 11, and a rotating cylinder 13, fixed frame 4, telescopic cylinder ① 1, support frame 5, limit switch ① 2, telescopic arm 6, telescopic cylinder ② 3, limit switch ② 7, mechanical claw fixed frame 8, wherein, the wheel bracket 12 is respectively connected with the wheel 10, The rotating bearing 11 is connected to the bearing chassis 9, and the bearing chassis 9 is connected to the rotating cylinder 13, and the rotating cylinder 13 is connected to the cylinder fixing frame 4, and the cylinder fixing frame 4 is connected to the telescopic cylinder ① 1 and the support frame 5 respectively. The telescopic cylinder ①1 is connected with the telescopic arm 6 and the limit switch ①2 respectively, the ...

Embodiment 2

[0024] Such as figure 1 As shown, a movable pneumatic manipulator, its use steps are as follows,

[0025] (1) A movable pneumatic manipulator is controlled by PLC programming. The air inlet and outlet are controlled by a two-position three-way solenoid valve, and the air pressure of each executive cylinder is controlled by a corresponding pressure regulating valve.

[0026] (2) Because there are wheels at the bottom of the linkage part of the mechanical claw, the manipulator can be pushed to any suitable position and then fixed.

[0027] (3) When starting to work, the rotary cylinder 13 moves to the specified position, stops, the telescopic cylinder ①1 moves, and reaches a certain position, then the telescopic cylinder ②3 moves, the mechanical claw descends, and the telescopic cylinder ③14 starts to move to a certain position. Air, the gripper 20 opens, then grabs the item, grabs the item, then the telescopic cylinder ②3 moves, the mechanical claw rises, and rises until the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com