Riveting tool for anti-loosening riveting bolt

A technology for riveting tools and riveting bolts, which is applied in the direction of bolts, screws, nuts, etc., can solve the problems of reducing the fatigue resistance of bolted joints, reducing the minimum tensile load of bolts, and not being able to fully exert the fastening force. The effect is important, Effects of weight reduction and increased fastening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

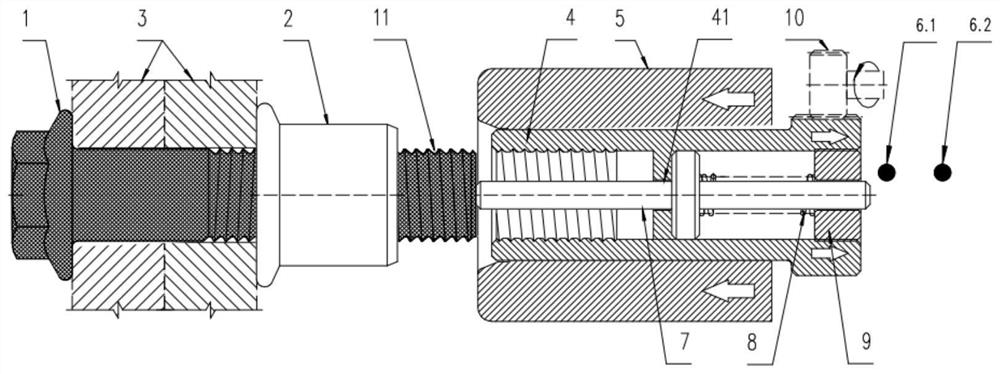

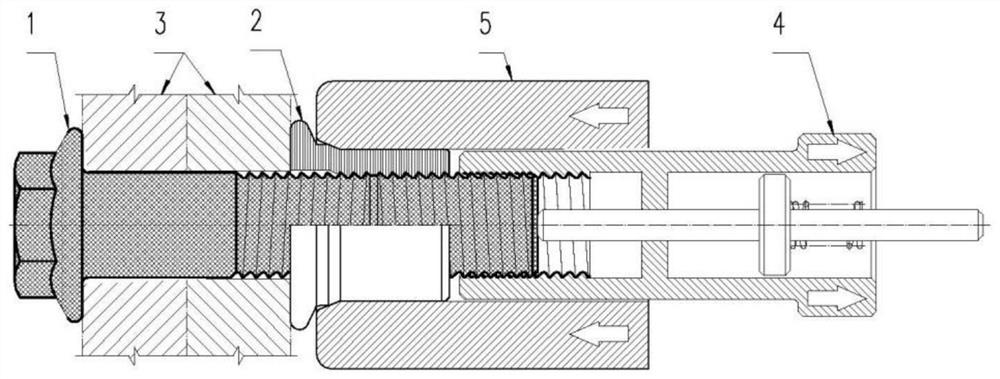

[0039] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

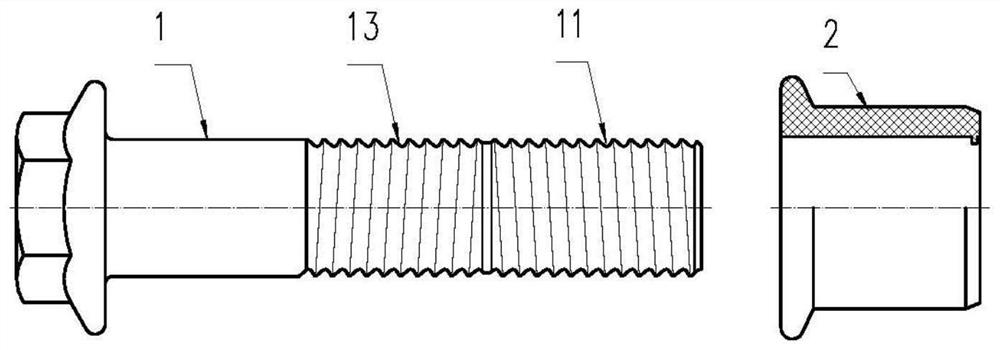

[0040] A riveting tool for riveting bolts. For the anti-loosening riveting bolts, the diameter of the entire length of the bolt shank 1 is the same, and there are threaded sections 11 with opposite directions of rotation on the bolt shank 1 and the riveting lock ring 2 for a length of engagement. 13, or screw to all consistent threads;

[0041] It is characterized in that: the riveting tool is composed of the extrusion die 5 of the outer cylinder and the tension sleeve 4 of the inner cylinder, which are driven by hydraulic power to move axially with each other, and the inner wall of the front end of the extrusion die 5 is in contact with the The shape of the lock ring 2 of the flange matches the shape, and the inner wall of the front end of the tension sleeve 4 is set to be the same as the screw direction and nominal parameters of the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com