Liquid storage device, vertical scroll compressor and refrigeration cycle system

A liquid storage device, vertical technology, applied in compressors, compressors, compressors with irreversible cycles, etc., can solve the problems of large gas flow resistance and low energy efficiency, and achieve the effect of less suction superheat and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

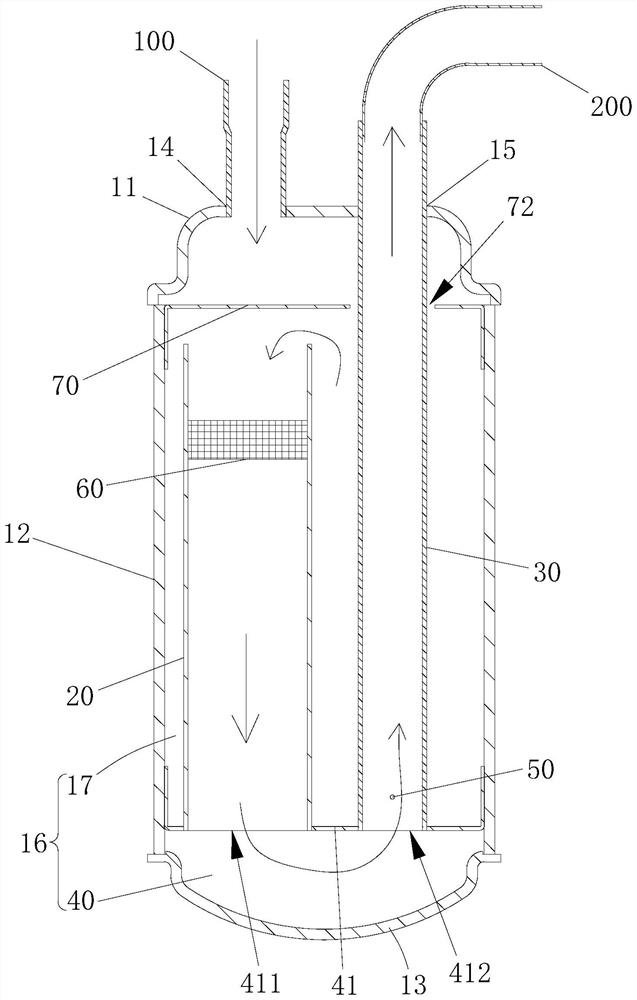

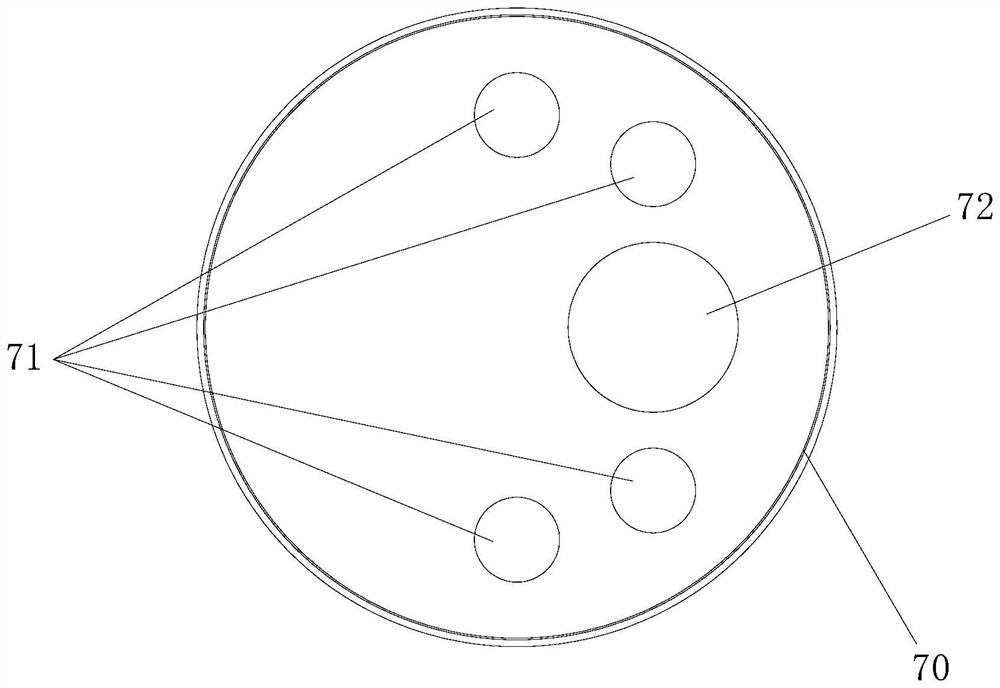

[0039] like figure 2 As shown, Embodiment 1 of the present invention provides a liquid storage device. Specifically, the liquid storage device includes a housing, a first delivery pipe 20, a second delivery pipe 30 and a buffer chamber 40. When specifically designed and assembled, the housing has a cavity 16, and the upper part of the housing is provided with an input port 14 and a buffer chamber 40. Output port 15, one of input port 14 and output port 15 is an air inlet, and the other of the two is an air outlet (in embodiment one, input port 14 is used as an air inlet, and output port 15 is used as an air outlet) , And, the lower part of the housing is provided with a buffer chamber 40 . The first delivery tube 20 is located in the cavity 16, the second delivery tube 30 is located in the cavity 16, the end of the first delivery tube 20 towards the top of the cavity is an open end, and the end of the first delivery tube 20 towards the bottom of the cavity 16 The other end ...

Embodiment 2

[0057] Compared with the liquid storage device of the first embodiment, the liquid storage device of the second embodiment has the following differences.

[0058] Such as Figure 5 As shown, one of the input port 14 and the output port 15 is opened on the top shell 11 , and the other of the input port 14 and the output port 15 is opened on the side shell 12 . In the liquid storage device of the second embodiment, the input port 14 is an air inlet, and the output port 15 is an air outlet. The opening at the end is higher than the air inlet, therefore, the gaseous refrigerant blown into the cavity 16 from the air inlet will first contact the wall of the first conveying pipe 20 and / or the second conveying pipe 30, and the gaseous refrigerant will carry The droplets will adhere to the tube wall of the first delivery tube 20 and / or the second delivery tube 30, and then the droplets will converge and fall along the tube wall to the bottom of the liquid storage chamber 17 for storag...

Embodiment 3

[0061] Compared with the liquid storage device of the first embodiment, the liquid storage device of the third embodiment has the following differences.

[0062] Such as Image 6 As shown, one of the input port 14 and the output port 15 is opened on the top shell 11 , and the other of the input port 14 and the output port 15 is opened on the side shell 12 . In the liquid storage device of the third embodiment, the input port 14 is an air inlet, and the output port 15 is an air outlet. end and the air inlet are staggered from each other, preventing the gaseous refrigerant entering the cavity 16 from the air inlet of the top case 11 from directly flowing into the opening end of the first conveying pipe 20, that is, preventing the liquid droplets carried by the gaseous refrigerant from directly entering The open end of the first delivery pipe 20 enters the compression chamber of the vertical scroll compressor to generate liquid hammer.

[0063] Such as Image 6 with Figure 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com